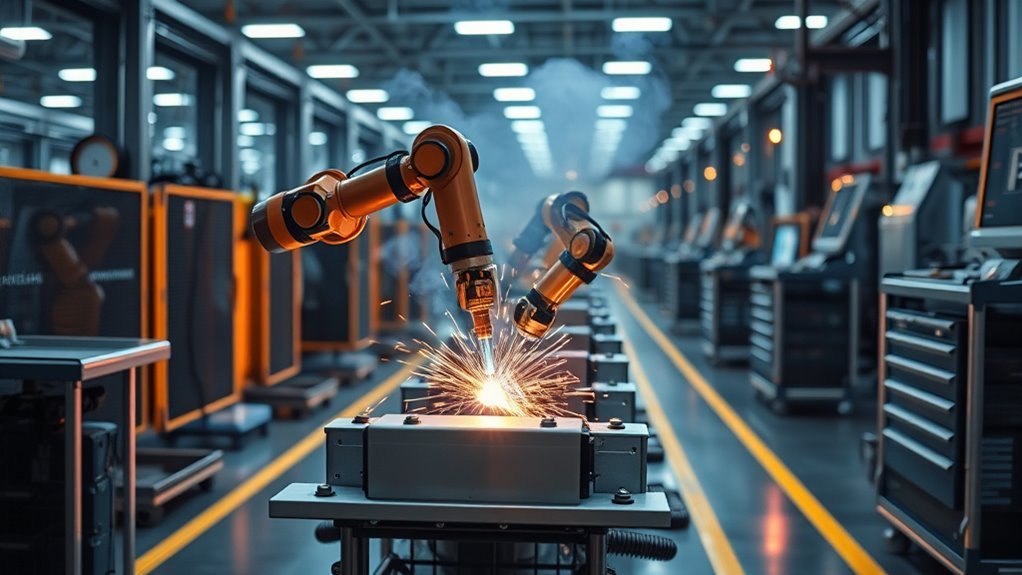

You’ll typically spend about $50,000 for a basic robotic welding cell and $150,000–$250,000 or more for a fully integrated system. Costs depend on robot class (Cartesian, SCARA, articulated, cobot), welding process, end‑effector complexity, safety enclosures, fume extraction, fixturing and integration. Expect installation, programming, maintenance and consumables to add ongoing costs that affect lifecycle value. Estimate TCO and ROI against takt time and part mix to choose the best solution if you want more detail.

Types of Welding Robots and Price Ranges

When budgeting for robotic welding, you’ll choose among Cartesian, SCARA, articulated-arm, and collaborative robots—each with distinct capabilities and cost profiles.

You’ll perform robot selection by matching application requirements to price bands: Cartesian and SCARA systems typically fall between $10,000 and $50,000, excelling in large-spot, TIG/MIG, and high-speed small-part tasks respectively.

Articulated-arm robots span roughly $50,000 to over $500,000, offering reach and dexterity for complex, hard-to-access welds.

Collaborative robots prioritize safe human interaction and can reduce enclosure costs while improving throughput; their pricing often overlaps lower-end articulated units.

For an analytical cost comparison, factor functionality per dollar, workspace constraints, cycle time, and integration complexity rather than just sticker price to determine lifecycle value.

Key Components That Drive System Cost

Although robot hardware usually takes the largest share of the budget, total system cost is driven by a bundle of interdependent components—robot body, welding power source and wire feed, end-effectors and guns, fixtures and tooling, safety enclosures and fume extraction, plus ongoing maintenance and programming.

You’ll budget robot hardware and welding systems first, but you must quantify complementary items: welding guns and tooling for part stability; safety enclosures and fume extraction to meet regulations; and integration labor.

Expect annual maintenance of roughly $2,000–$5,000 depending on robot type and duty cycle. Programming and setup add one-time and recurring costs when part designs change.

Evaluate total cost as a systems problem: optimize component selection and lifecycle expenses rather than focusing solely on upfront robot hardware price.

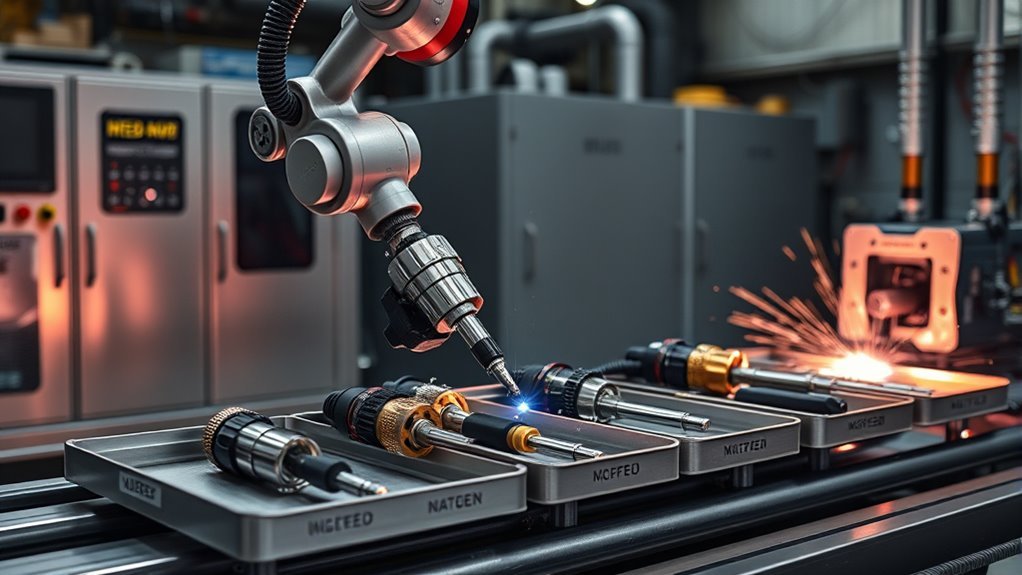

End-Effector Options and Their Price Impact

Having budgeted robot hardware and supporting systems, you now need to evaluate end-effectors because their selection materially shifts both upfront and lifecycle costs. You’ll assess end effector types — spot, TIG, laser, electron-beam, and specialty rigs — against performance needs. Pricing strategies vary: bundled basic guns lower entry cost; modular or bespoke units raise capital and service expenses. High-tech end-effectors improve throughput and quality but add tens of thousands to system price; niche aerospace or defense designs can spike costs further. Choose by duty cycle, joint geometry, and maintenance profile to balance ROI and operating expense. Below is a simple emotional prompt to focus decision gravity:

| Choice | Cost impact | Emotional weight |

|---|---|---|

| Spot | Low | Relief |

| TIG/laser | Medium | Caution |

| Electron-beam/specialty | High | Anxiety |

Safety, Facility, and Integration Expenses

Because safety, facility layout, and integration shape both capital and ongoing costs, you should budget for enclosures, fume-extraction, emergency interlocks, adequate floor space, and tailored software as part of the system price.

Budget for enclosures, fume extraction, interlocks, floor space, and custom software—safety and integration drive system cost.

You’ll face capital outlays to meet safety regulations: welded-cell fencing, interlocks tied to robot controllers, and industrial extraction sized for welding fume loads.

Facility layout dictates cell footprint, material flow, and utility routing; inefficient layouts raise installation and operating costs.

Integration expenses include custom I/O, communication protocols, and controller configuration so the robot fits existing conveyors and PLCs.

Plan for periodic verification of safety systems and software updates as ongoing expenses.

Accurate line-iteming of these elements prevents scope creep and improves ROI forecasts for robotic welding deployment.

Programming, Maintenance, and Consumables Costs

You’ll need to budget for programming setup costs, which can include internal hours or outsourcing fees and scale with cell complexity.

Plan annual maintenance expenses—typically $2,000–$5,000 depending on robot type—and schedule inspections, software updates, and component replacement to preserve uptime.

Account for consumables and replacement parts, noting robots use materials more efficiently but still incur $1,000–$3,000 monthly in welding-specific supplies.

Programming Setup Costs

When planning robotic welding, factor in programming setup alongside ongoing maintenance and consumables to get realistic operating costs. You’ll evaluate programming efficiency and outsourcing options to minimize downtime and per-part cost.

Consider these components:

- Initial programming — in-house setup using teach pendants; requires operator training and time allocation.

- Reprogramming — new-part cycles or design changes; outsourcing typically billed $100–$200/hr.

- Consumables impact — welding gas, wire, tips; robotic consistency reduces waste, lowering monthly spend.

- Budgeting margin — include estimated annual maintenance ($2,000–$5,000) and monthly consumables ($1,000–$3,000) when calculating break-even.

Quantify hourly rates, training hours, and frequency of reprogramming to model total cost per part precisely.

Ongoing Maintenance Expenses

Although robotic welding cuts per-part labor, ongoing expenses for programming, maintenance, and consumables remain a significant portion of operating cost and must be quantified precisely.

You should budget robotic maintenance at roughly $2,000–$5,000 annually, variable by robot class and duty cycle. Programming adds discrete costs: initial pathing and periodic reprogramming for new parts either consume internal engineering hours or incur outsourcing hourly fees.

Consumables are material-usage driven and typically fall between $1,000–$3,000 per month, though efficient systems can lower waste. Regular inspections, software updates, and proactive component servicing reduce unplanned downtime and preserve throughput.

For effective cost management, model annual totals combining maintenance, programming labor, and monthly consumables, then run sensitivity scenarios against utilization and reprogramming frequency.

Consumables and Replacement Parts

Because consumables and replacement parts drive recurring spend, you should treat them as predictable line items and track them alongside programming and maintenance labor.

You’ll typically see monthly consumable expenses of $1,000–$3,000 and annual maintenance of $2,000–$5,000; include outsourced programming hourly fees when estimating total operating cost.

Robots improve welding efficiency, lowering wire and gas waste and enabling measurable cost reduction versus manual processes.

- Track monthly consumable usage (wire, gas) and unit costs.

- Budget annual maintenance and spare parts based on robot type and duty cycle.

- Account for programming/reprogramming labor and potential contractor rates.

- Monitor KPIs (consumable per part, downtime, repair frequency) to validate cost reduction and optimize procurement.

Calculating Total Cost of Ownership and ROI

If you’re evaluating a robotic welding purchase, calculate total cost of ownership (TCO) by summing the initial capital outlay (typically $50,000–$150,000+), installation ($10,000–$25,000), and predictable recurring costs—consumables ($1,000–$3,000/month) and maintenance ($2,000–$5,000/year)—then compare that to quantified savings from up to 50% labor reduction, lower material waste, and productivity gains (systems can reach ~85% overall efficiency and 95% arc-on time) to estimate payback (commonly 1–3 years) and multi-year ROI.

| Item | Typical Range |

|---|---|

| Initial purchase | $50,000–$150,000+ |

| Installation | $10,000–$25,000 |

| Consumables (monthly) | $1,000–$3,000 |

| Maintenance (annual) | $2,000–$5,000 |

Model net present value, annualized savings, and return investment to support capital approval.

Choosing the Right Robot for Your Production Needs

When specifying a welding robot, start by mapping your part geometry, cycle time targets, and access constraints to the robot class and end effector: Cartesian systems suit large, linear welds; articulated arms handle complex geometries and hard-to-reach joints; SCARA fits high-speed, precision work on small-to-medium parts and typically costs $10k–$50k.

You’ll evaluate robot selection criteria and application considerations to balance upfront cost, duty cycle, and future flexibility.

- Define production volume, takt time, and required reach to narrow classes.

- Compare end-effectors (spot guns to electron-beam) for throughput and cost impact.

- Allocate budget for safety enclosures, fume extraction, and integration.

- Prefer modular systems for upgrades, reducing long-term replacement expense.

Frequently Asked Questions

Can Robotic Welders Operate Unattended Overnight or Weekends?

Yes — you can run robotic welders unattended overnight or weekends. You’ll boost robotic efficiency and realize automation benefits, but you’ll need reliable programming, remote monitoring, safety interlocks, preventive maintenance, and quality checks to prevent downtime and defects.

What Training Is Required for Operators and Programmers?

You need operator certifications and programming skills: obtain welding safety and robot operator certifications, plus training in robot programming languages, motion planning, welding parameters, troubleshooting, and PLC/HMI basics; hands-on practice and periodic recertification are required.

How Does Warranty Coverage and Service Contract Pricing Work?

Like a safety net, you’ll get warranty terms defining coverage, exclusions, and duration, while service agreements list rates, response times, and SLAs; you’ll analyze total lifecycle cost, compare options, and negotiate extensions or performance clauses.

Are There Financing or Leasing Options Available for Purchases?

Yes — you can access financing options and leasing agreements; you’ll evaluate interest rates, term lengths, residual values, and tax implications, model cash flow impacts, compare vendor versus third‑party terms, and choose the most cost‑efficient structure.

Can Existing Jigs and Fixtures Be Reused With a Robot?

Yes—you can often reuse existing jigs and fixtures, but you’ll assess jig compatibility, perform fixture modification for robot access, add tooling or sensors, and validate tolerances; expect iterative adjustments to guarantee repeatable, safe robotic welding operation.

Conclusion

You’ve seen how robot type, payload, end‑effector, safety, integration, programming, and upkeep shape price — but the real question is what those numbers mean for your floor. Crunch the TCO: upfront equipment, cell build, installation, training, spare parts, and energy versus throughput gains, scrap reduction, and labor redeployment. Don’t rush the selection; pick a configuration that meets cycle, accuracy, and duty‑cycle needs. Do that, and the investment either pays off — or tells you to walk away.