Updated on 2025-11-25

Accurately estimating welding costs is critical for profitable manufacturing and construction bids. By breaking down the process into unit costs, you can derive a precise cost per inch.

To calculate welding cost per inch, sum labor, materials, equipment, and overhead expenses, then divide by the total weld length. Measure arc-on time for labor, weight of filler metal and gas for materials, and amortized machine costs for equipment. Apply recovery factors to account for efficiency losses.

Key Takeaways

- Four Pillars: Break costs into Labor, Materials, Equipment, and Overhead.

- Unit Precision: Calculate all expenses per inch of weld to allow scalable bidding.

- Volume to Weight: Convert weld volume (Area × Length) to weight to estimate filler metal needs.

- Recovery Factors: Always adjust theoretical material needs for efficiency (typically 60–70% for manual processes).

Understanding the Components of Welding Cost

When you calculate welding cost, break it down into four measurable components—labor, materials, equipment, and overhead. This allows each to be quantified and traced to specific line items. Start by listing hourly rates, material pricing, equipment depreciation, and fixed facility charges.

You’ll quantify labor by multiplying the welder’s hourly wage (plus benefits) by task hours. Always adjust for labor efficiency using a multiplier to account for rework or idle time.

For materials, sum the cost of the base metal, filler, shielding gas, and consumables per joint length. Equipment costs are derived from purchase or rental prices amortized over expected hours, plus maintenance and power consumption. Finally, overhead allocates utilities, rent, administration, and safety gear proportionally. Record each figure as a unit cost to enable precise per-inch calculations.

Defining the Scope and Measuring Total Weld Length

After you’ve quantified labor, materials, equipment, and overhead as unit costs, define the work scope and measure total weld length so every cost can be allocated accurately.

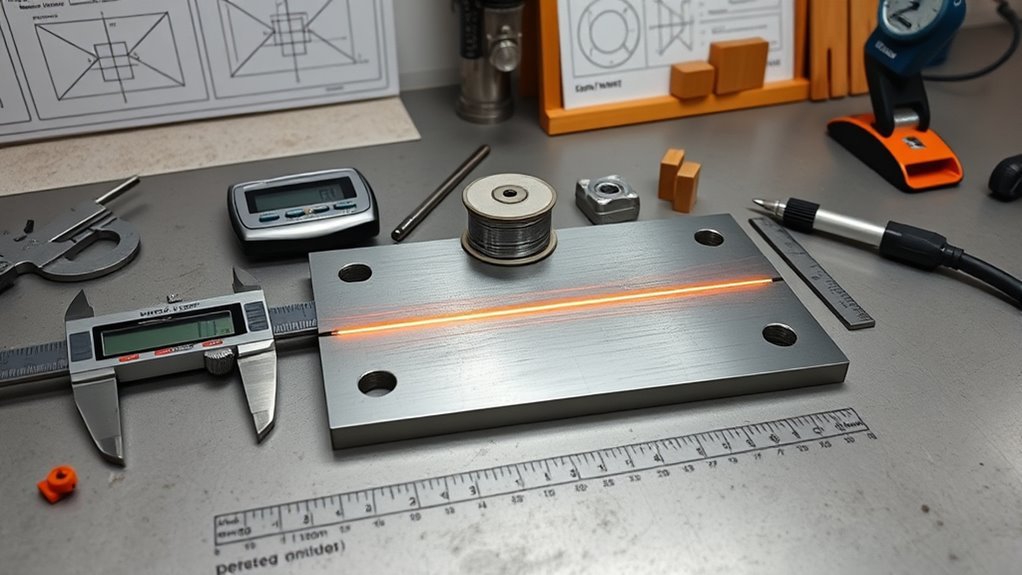

First, list each component and identify weld types and geometry: butt, fillet, beveled, or other weld joint configurations. For each joint, record start/stop points and any gaps or preparation that affect length. Use precise measuring tools—calipers for small features, measuring tapes or laser distance tools for long runs—and log measurements consistently in inches or millimeters.

Sum all joint lengths to produce a verified total weld length. Maintain a tabulated record noting joint type, measured length, units, and tolerances; this dataset feeds your per-inch material and labor calculations.

Selecting the Appropriate Welding Process

Because material type, joint geometry, and service conditions directly determine process suitability, start by listing requirements. Note the base metal, thickness, joint type, required weld strength, and appearance standard. Map those items to candidate processes. For example, use GTAW (TIG) for thin aluminum or stainless steel requiring high-quality appearance, or FCAW/SMAW for thick steel in outdoor conditions.

Next, quantify the job. Count parts by metal (e.g., 50 steel, 20 aluminum), measure thickness ranges, and classify joints. For each class, assign welding techniques ranked by material compatibility and deposition rate. Record expected productivity (in/min or in/hr) and consumable costs ($/lb). Refer to standards from the American Welding Society (AWS) to ensure your process selection meets code requirements.

Use these metrics to select the process that minimizes total cost while meeting strength and appearance goals.

Calculating Weld Metal Volume and Weight

Accurate weld-metal calculations start with the simple relation V = A × L. First, determine the weld cross-sectional area (A) for the joint type and multiply it by the weld length (L) to get volume in cubic inches or cubic centimeters.

Example Calculation:

If Area (A) = 2.47 in² and Length (L) = 14 in:

V = 2.47 × 14 = 34.6 in³

For weight calculation, multiply that volume by material density: Weight = V × Density. Using a steel density of roughly 0.283 lb/in³ (source: MatWeb), the calculation is:

Weight = 34.6 × 0.283 ≈ 9.62 lb

Record units, round consistently, and note the density source. These numeric steps allow you to quantify material needs and drive per-inch cost estimates.

Estimating Filler Metal and Shielding Gas Consumption

Estimating filler metal and shielding gas starts with the weld volume you already calculated. You must convert that theoretical volume into the actual consumables you’ll buy.

Convert volume (V) to weight by multiplying by filler metal density. Divide the required filler weight by the rod or wire unit weight to get the units needed.

Tip: Convert weld volume to weight using filler density (e.g., 0.284 lb/in³), then divide by rod or wire unit weight.

Adjust for filler metal efficiency. For many processes, efficiency is 60–70%.

Required purchase = Calculated need / Efficiency

Estimate shielding gas by selecting the process and joint. Set the flow rate (CFM) and calculate total cubic feet using: Total = CFM × welding time (minutes) / 60. Alternatively, use per-inch empirical consumption rates. Multiply purchased quantities by unit costs to get the total material expense.

Determining Labor Time and Labor Costs

Having calculated consumables, you now quantify the labor required to lay those welds. First, measure total joint length and divide by welder travel speed (inches per minute) to get arc-on minutes; convert this to hours.

Use arc time as the numerator in the operating factor (OF = arc time / total shift time) to reflect labor efficiency. Typical arc-on time is only 20–40% of a shift. Adjust arc time by the OF to estimate productive labor hours.

Multiply the resulting hours by a realistic labor rate (wage plus benefits and payroll burdens)—usually $55–$60/hr—to get total labor cost. Finally, divide total labor cost by total welded inches to produce a precise labor cost per inch.

Adding Equipment, Power, and Overhead Expenses

Now add equipment and power to the per-inch calculation. List each welder and ancillary tool, assign annual depreciation or rental and maintenance costs, then divide by expected annual weld inches to get equipment cost per inch.

Calculate power by measuring total kWh used for the welding cycles and multiplying by your local rate to produce a kWh cost per inch. Combine these figures with labor and material costs for a complete estimate.

Equipment Depreciation Costs

Equipment costs drive the baseline of any estimate. Calculate depreciation from the purchase price minus residual value, divided by the estimated useful life. Convert that to a per-inch charge by dividing by annual productive hours or expected total weld inches. Allocate overhead proportionally after deriving per-inch depreciation.

| Item | Annual Cost | Per-Inch Charge |

|---|---|---|

| Purchase depreciation | $2,400 | $0.12 |

| Maintenance & repairs | $600 | $0.03 |

| Allocated overhead share | $1,200 | $0.06 |

| Total | $4,200 | $0.21 |

Power and Utilities

Start by quantifying the power you’ll charge. Calculate kWh consumption from welding voltage and amperage, adjust for machine efficiency and duty cycle, then multiply by your local electricity rate.

Add equipment-related charges by prorating welding machine depreciation. Sum direct utility consumption (electricity, gas) and apply current utility pricing. Finally, allocate overhead by dividing facility rent, administrative costs, and insurance across billable inches. Total per-inch cost = energy + equipment depreciation + utilities + allocated overhead.

Computing Cost Per Inch and Applying Recovery Factors

When you break the job down to dollars per inch, sum the total labor, materials, consumables, overhead, and power costs. Divide that sum by the total weld length in inches to get a precise cost-per-inch.

Be sure to adjust consumable quantities using the recovery factor for the chosen welding process. This ensures your filler-metal weight reflects actual usage rather than theoretical deposition.

Practical Tips, Examples, and Common Pitfalls

Now that you’ve converted expenses into a verified cost-per-inch, turn your attention to practical adjustments.

- Contingency: Add a 5–15% contingency buffer.

- Benchmarking: Compare against past projects. If a prior average was $0.75/in and your calculation is $0.60/in, investigate potential missed prep or travel time.

- Scenario Planning: Prepare best-case and worst-case scenario tables for budgeting.

- Recovery Factors: Never omit recovery factors; they are the most common source of material shortages in estimates.

Frequently Asked Questions

How do taxes affect welding cost per inch?

Taxes increase per-inch costs by adding percentage-based liabilities to labor and materials. You must apply specific tax rates to each category before summing the final unit price.

Can subcontractor rates be used in the calculation?

Yes. Convert subcontractor quoted rates to hourly equivalents, add material and overhead markups, and calculate a weighted average cost per inch based on production rates.

How to account for inspection and testing costs?

Itemize technician hours, equipment depreciation, and consumables for methods like NDT. Divide the total inspection cost by total welded inches to get the per-inch inspection cost.

Should scrap and rework be included per weld inch?

Yes. Quantify historical scrap rates and rework hours, then allocate these costs proportionally to the per-inch rate to ensure budgeting covers material loss and efficiency gaps.

How to price travel and mobilization per inch?

Total all travel and mobilization fees for the project, divide by the total estimated weld inches, and add a contingency percentage to derive a per-inch allocation.

Conclusion

You now have a methodical way to get welding cost per inch: measure total weld length, choose a process, calculate weld volume, and estimate all inputs including overhead and recovery factors. Using templates and pre-calculated tables speeds up this granular process. Rely on real shop data to keep your bids competitive.