A Miller laser welding cell typically costs between $20,000 and over $100,000, depending on various factors like model, features, and customization options. Standard features start around $50,000, with upgrades and automation potentially increasing the price by 10-30%. Additional expenses may include accessories and ongoing training. The investment can lead to enhanced productivity and lower maintenance costs. If you’re curious about how these elements impact your decision, there’s more to explore on this topic.

Understanding Laser Welding Technology

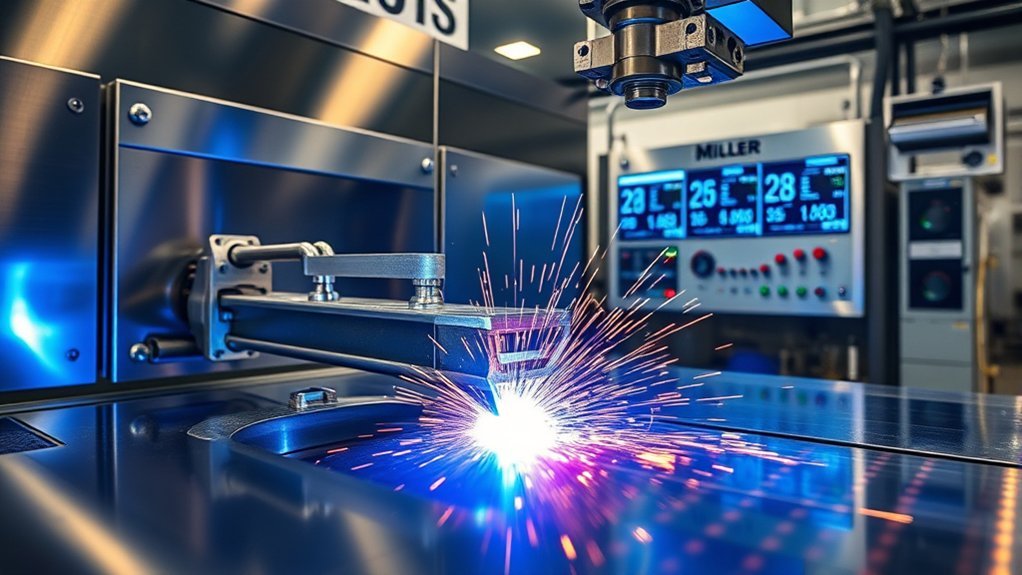

Understanding laser welding technology is essential for anyone looking to enhance their welding processes. This method utilizes focused laser beams to join materials, offering unparalleled precision and minimal thermal distortion compared to traditional techniques.

You’ll find that the Miller Optics 2kW laser welder effectively joins various metals, including mild steel, aluminum, stainless steel, and titanium, all without filler materials. The process leverages fiber optics to transmit laser light, enabling versatile applications such as spot welding, wire welding, and surface cleaning.

One of the key advantages is the impressive travel speed of up to 20 inches per minute, with adjustable settings tailored to specific project needs, greatly boosting production efficiency.

Additionally, laser welding’s cleaning capability strips away rust and oxidation, eliminating the need for time-consuming traditional cleaning methods like pickling and passivating. This technology not only streamlines operations but also improves overall quality in welding applications.

Key Features of the Miller Optics 2kW

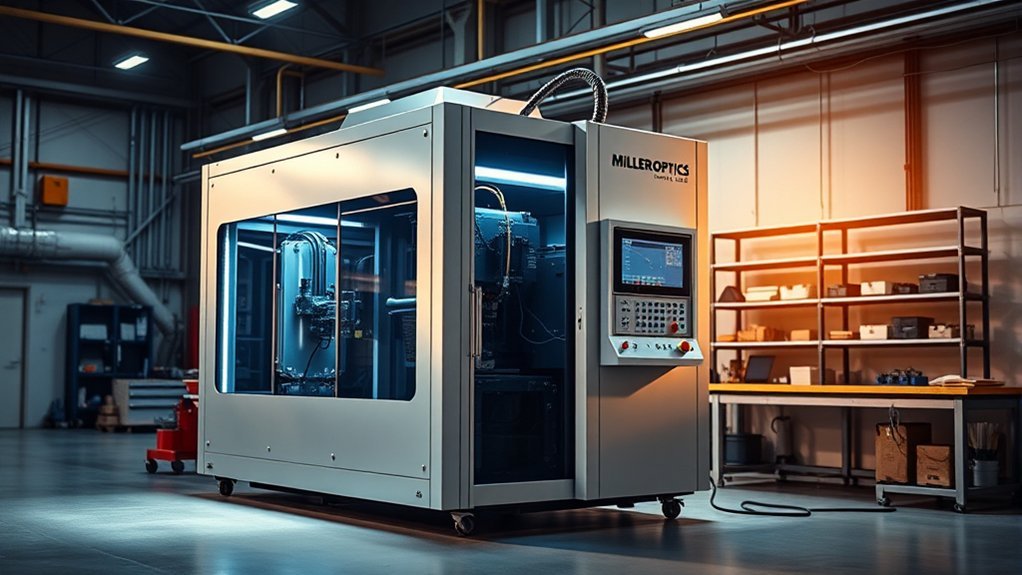

The Miller Optics 2kW laser welder showcases advanced laser technology that enhances precision in various welding applications.

You can perform spot welding, wire welding, and cleaning tasks without filler material, making it highly versatile.

With its ability to handle multiple materials, this welder meets diverse industrial needs efficiently.

Advanced Laser Technology

When you explore the capabilities of the Miller Optics 2kW laser welder, you’ll notice its advanced laser technology markedly enhances welding efficiency.

This system employs fiber optics to transmit laser light, enabling precise welding without filler material. You can weld various materials, including mild steel, aluminum, stainless steel, and titanium, making it adaptable for different projects.

The dual laser lenses not only improve safety but also guarantee protection during the welding process. With adjustable speed settings, you can operate the welder at a travel speed of 20 inches per minute for wire welding, meeting diverse requirements.

Additionally, the built-in cleaning function effectively eliminates rust and oxidation, simplifying maintenance compared to traditional methods like pickling and passivating.

Versatile Welding Applications

While exploring the versatile applications of the Miller Optics 2kW laser welder, you’ll find it adept at tackling a wide range of materials, including mild steel, aluminum, stainless steel, and titanium.

This welder excels in various welding techniques, enabling flexibility for your projects.

- Performs welding without filler material, enhancing efficiency.

- Conducts spot and wire welding at speeds up to 20 inches per minute.

- Offers a cleaning capability of 15 mm, effectively removing rust and oxidation.

With integrated safety features, like a continuity clamp that prevents accidental firing, you can work confidently.

The Miller Optics 2kW truly stands out for its multifunctionality, making it a valuable asset for diverse welding applications.

Factors Influencing the Cost of Laser Welding Cells

Various factors contribute to the cost of a Miller laser welding cell, making it essential for buyers to understand these influences before making a purchase.

First, the specific model and features dictate pricing, typically ranging from $20,000 to over $100,000. The power output of the laser, such as a 2kW option, considerably affects capabilities and applications, leading to cost variations.

Advanced technologies, like fiber optics for laser transmission and safety features, can increase the overall price.

You should also consider additional costs for necessary accessories, including welding fixtures, protective gear, and maintenance tools.

Finally, the complexity of supported welding processes, such as spot welding, wire welding, and cleaning, can further influence pricing based on the versatility required for your specific projects.

Understanding these factors will help you make an informed decision when investing in a Miller laser welding cell.

Comparison of Miller Optics With Other Laser Welders

Miller Optics laser welders stand out in a competitive market due to their advanced fiber optic technology and versatile capabilities. Unlike many traditional welders, the Miller Optics 2kW model eliminates the need for bulky setups, ensuring a streamlined operation.

Its ability to perform ayous welding without filler material gives you flexibility across various applications.

Consider these key differentiators:

- Material Compatibility: Welds mild steel, aluminum, stainless steel, and titanium, unlike some competitors with limited options.

- Integrated Cleaning Features: Effectively strips rust and oxidation, enhancing efficiency compared to models lacking this capability.

- Enhanced Safety: Includes a continuity clamp for user safety, setting it apart from other systems that may overlook such protective mechanisms.

With these advantages, the Miller Optics 2kW laser welder proves to be a superior choice for diverse welding needs.

Customization Options and Their Impact on Price

When considering a Miller laser welding cell, it’s essential to evaluate how customization options affect your overall investment.

Standard features may provide a baseline price, but optional accessories and enhancements can greatly increase costs, sometimes by 30% or more.

Analyzing these customization impacts will help you understand the trade-offs between initial expenditure and long-term operational efficiency.

Standard Features Pricing

The Miller Optics 2kW laser welder offers a solid foundation with its standard features, starting at around $50,000. This pricing includes essential components that enhance functionality and safety, but customization options can considerably increase your investment.

Consider these standard features included in the base price:

- Fiber optics transmission for efficient energy transfer

- Dual laser lenses that improve versatility

- Safety continuity clamps ensuring user protection

When evaluating your options, remember that additional features or advanced control systems can raise costs anywhere from a few thousand to tens of thousands.

Additionally, factor in maintenance and potential upgrades when examining the total investment required for a customized welding cell, ensuring you make an informed decision.

Optional Accessories Costs

As you consider the base price of the Miller Optics 2kW laser welder, it’s important to explore optional accessories that can enhance its capabilities and tailor it to your specific needs.

Additional fiber optic cables, varying in price depending on length and specifications, can add several hundred dollars to your investment. Specialized lenses and attachments for different welding techniques can also impact the overall cost based on their complexity.

Furthermore, safety accessories, including enhanced protective gear, play an essential role in operator safety and can increase your initial costs. Maintenance kits, incorporating replacement parts and cleaning supplies, should be factored into ongoing expenses.

Finally, integrating automation options, like robotic arms, notably elevates costs while improving productivity and precision.

Customization Impact Analysis

While evaluating the cost of a Miller Laser Welding Cell, you’ll find that customization options can greatly influence the overall price. These choices can transform your investment markedly, often adding thousands of dollars to the base cost.

Consider the following factors:

- Upgraded control systems and software can increase the price by 10-30%.

- Automation integration, like robotic arms, can escalate costs considerably.

- Specialized training and support services for custom setups may incur ongoing expenses.

Aesthetic choices, while less impactful, can still contribute to the overall price.

Therefore, understanding how these customizations affect your budget is vital for making an informed decision on your Miller Laser Welding Cell purchase.

Financing Options for Purchasing a Laser Welder

Exploring financing options for purchasing a Miller laser welder can greatly ease the financial burden on your business. You can consider various avenues, including equipment leasing, in-house financing from manufacturers, and third-party lenders. These options often come with flexible terms and manageable monthly installments.

Here’s a breakdown of financing options:

| Financing Option | Benefits | Considerations |

|---|---|---|

| Equipment Leasing | Lower upfront costs | Long-term commitment |

| In-House Financing | Competitive interest rates | Limited availability |

| Government Grants | Offset purchase costs | Application process |

| Trade-In Programs | Reduces initial price | Dependent on existing equipment |

Cost-Benefit Analysis of Investing in Laser Welding

When considering the initial investment in a Miller Optics 2kW laser welder, it’s important to weigh the upfront costs against potential long-term savings.

This technology not only boosts efficiency and productivity but also minimizes the need for filler materials and extensive surface preparation.

Initial Investment Considerations

Investing in a Miller Optics 2kW laser welder can seem challenging due to the initial costs, which typically range from $15,000 to $30,000, depending on features and installation.

However, this initial expenditure can provide significant advantages that may justify the investment.

- Enhanced productivity: The high precision and speed of laser welding allow for quicker project turnaround.

- Versatility: You can work with various materials like aluminum, stainless steel, and titanium, broadening service offerings.

- Lower maintenance costs: Laser systems often require less frequent repairs compared to traditional welding equipment.

Long-Term Savings Potential

While the initial costs of a Miller Optics 2kW laser welder might seem intimidating, the long-term savings potential makes it a prudent investment for many businesses.

By eliminating the need for filler material, you’ll greatly reduce material costs over time. The welder’s efficiency, operating at speeds up to 20 inches per minute, decreases labor costs compared to traditional methods.

Additionally, its cleaning capabilities remove the need for expensive processes like pickling, enhancing savings further. With versatility in welding materials such as mild steel and titanium, you’ll minimize the need for multiple machines.

Plus, robust safety features can lower workplace accidents, potentially reducing insurance premiums and liability costs, making this investment even more attractive in the long run.

Efficiency and Productivity Gains

By adopting the Miller Optics 2kW laser welder, you can achieve remarkable efficiency and productivity gains that directly impact your bottom line.

This advanced technology dramatically reduces welding time, allowing for spot welding in just two counts and wire welding at a speed of 20 inches per minute.

Consider these benefits:

- Reduced Labor Costs: The laser’s cleaning capability minimizes the need for post-welding preparation.

- Lower Material Expenses: Welding without filler material cuts down on waste and costs.

- Increased Project Versatility: Capable of welding various materials, you can expand your project offerings and revenue streams.

Investing in this laser welder positions your business for enhanced productivity and profitability.

Maintenance and Operating Costs to Consider

When operating a Miller Optics 2kW laser welder, you’ll encounter several maintenance and operating costs that can impact your budget.

First, consider the periodic replacement of fiber optic components, which varies based on how intensely you use the equipment.

Next, electricity consumption is a significant factor; the 2000-watt laser demands a reliable power source for peak performance.

Regular cleaning and servicing are vital, and these costs can add up to guarantee your welder remains functional and efficient over time.

Additionally, don’t forget about consumables like protective gear and safety equipment for operators, which are necessary for compliance and safety.

Training for operators is also essential to maximize the welder’s capabilities, potentially leading to further expenses for workshops or certification courses.

Future Trends in Laser Welding Technology

As maintenance and operating costs shape your laser welding budget, staying informed about future trends in laser welding technology can enhance your investment strategy.

The global laser welding market is set to expand, driven by advancements in automation and precision welding techniques. Innovations in fiber laser technology are improving efficiency, while AI and machine learning are optimizing processes in real-time.

The laser welding market is poised for growth, fueled by automation advancements and real-time optimization through AI and fiber laser innovations.

Key trends to watch include:

- Increased adoption of laser welding in industries like automotive and aerospace, favoring lightweight materials and intricate designs.

- Enhanced operational efficiency through AI-driven process adjustments, reducing waste and improving quality.

- A shift towards sustainable practices, including eco-friendly laser cleaning methods that minimize environmental impact.

Where to Purchase the Miller Optics 2kW

Purchasing the Miller Optics 2kW laser welder is straightforward, thanks to a network of authorized distributors and dealers listed on the official Miller websites.

You can find detailed information on purchasing options by visiting miller.com or millerwelds.com. Pricing for the 2kW model may vary depending on the distributor and any additional features or accessories included in your order.

It’s essential to explore nearby retailers to compare prices and options effectively. Some distributors offer financing or leasing agreements, making it easier for businesses to acquire the welder without a hefty upfront cost.

When considering your purchase, check for ongoing promotions or discounts from authorized dealers, as this could greatly impact your final price.

Frequently Asked Questions

What Is the Warranty Period for Miller Laser Welding Cells?

Miller laser welding cells typically come with a warranty period of one to three years, depending on the specific model and components. Always check the manufacturer’s details for precise warranty information and coverage policies.

Are There Training Programs Available for Using the Miller Optics?

Yes, Miller offers training programs for using their optics. For instance, a recent workshop in Ohio improved participants’ precision and efficiency by 30%, demonstrating how effective these programs are in enhancing operational skills.

How Do I Determine the Best Model for My Needs?

To determine the best model for your needs, assess your project requirements, material types, thicknesses, and production volume. Compare specifications, features, and reviews of available models, ensuring compatibility with your existing equipment and operational goals.

What Support Services Are Offered After Purchase?

After purchase, you’ll receive technical support, training programs, and maintenance services. These services guarantee your equipment operates efficiently, helping you troubleshoot issues and optimize performance, ultimately maximizing your investment in the welding cell.

Can I Get a Demo Before Purchasing a Miller Laser Welder?

Absolutely, you can arrange a demonstration before making your purchase. This allows you to experience the machine’s capabilities firsthand, ensuring it meets your specific needs and expectations. Just contact your local distributor to set it up.

Conclusion

In the world of precision welding, investing in a Miller laser welding cell is like planting seeds in fertile soil; with the right care, they’ll yield remarkable results. By understanding the costs involved and weighing the benefits, you can make an informed choice that propels your operations forward. As technology evolves, staying ahead of trends guarantees your investment remains fruitful. So, plunge into the details, and let your welding capabilities shine like a well-aimed laser beam.