Welding does use a noticeable amount of electricity, but how much depends on the machine type, amperage, duty cycle and run-time; small household 110V MIGs typically draw 1–2 kW, mid-range units 2–4 kW, and heavy industrial or three-phase systems can exceed 7–8 kW. Duty cycle controls how long you can weld at full output and affects cumulative kWh. Calculate cost by multiplying operating kW by hours and your rate, and below you’ll find practical examples and savings tips.

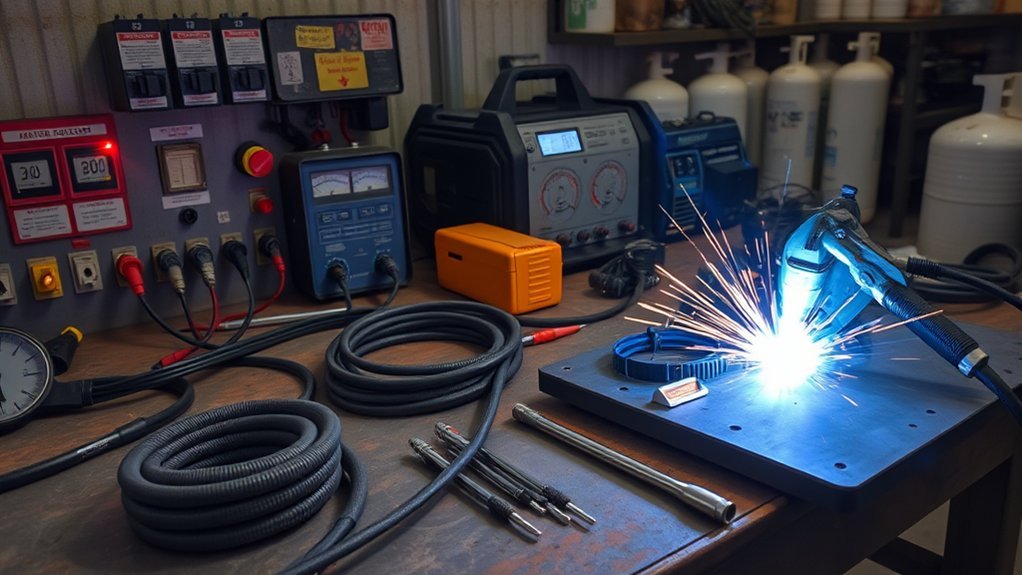

How Welding Machines Consume Electricity

Welding machines draw power according to their design, duty cycle, and operating amperage, so you’ll see consumption range from roughly 1,000–2,000 W for small household units to over 7,800 W for heavy industrial welders; TIG systems are the most efficient, typically using about 3–5 kWh, while common machines run 5–15 kWh per hour depending on load.

You’ll notice consumption rises with amperage and continuous duty: higher current and longer active intervals multiply energy draw, pushing monthly kWh upward (for example, a 15 kW 3‑phase welder used 20 minutes across 150 operations can total ~740.5 kWh).

To manage welding efficiency, monitor duty cycle, amperage, and arc time; choose equipment matched to task rather than oversizing.

Also evaluate energy sources—single‑phase vs 3‑phase supply and available voltage affect inverter performance and losses.

Tracking these variables helps you predict costs, maintain safety margins, and optimize throughput without wasting electricity.

Typical Power Ranges by Welder Type

When you match a welder to a job, expect power draw to vary substantially by type: small 110V household MIGs typically pull about 1,000–2,000 W, mid‑range commercial units run roughly 2,000–4,000 W, and heavy industrial or three‑phase systems can draw 4,000 W up to and beyond 7,800 W.

You’ll select based on task size and available service: 110V units suit light repairs and hobby work, 240V commercial machines handle thicker materials and longer welds, and three‑phase industrial welders support continuous, high-current applications.

Compare welding power ratings against your site capacity to avoid circuit overloads. Also factor welder efficiency—modern inverters deliver higher arc stability and lower input power for the same output than legacy transformer designs, reducing operating cost per weld.

Compare welder ratings to site capacity to prevent overloads, and prefer efficient inverter units to lower input power and operating cost.

Use nameplate wattage and typical operating draw to estimate supply needs and running cost. This technical matching guarantees you get adequate performance without overspecifying equipment or stressing electrical infrastructure.

How Duty Cycle Affects Energy Use

Because the duty cycle defines the percentage of time a machine can run at full-rated output within a fixed interval (commonly 10 minutes), you can directly predict operating energy by matching expected weld-on time to that percentage.

You’ll use duty cycle implications to size workload and avoid overheating; a 60–80% machine sustains longer continuous welds and consequently consumes more electricity during extended runs. Conversely, lower-duty machines draw less over a shift, so they’re efficient for intermittent tasks.

Apply power management by planning weld sequences, staggering jobs, or selecting a higher-capacity unit only when necessary. For example, a 15 kW three-phase welder used at rated output for 20 minutes across a month can yield substantial kWh totals, so match duty cycle and expected run-time to limit wasted energy and downtime.

- You’ll feel relieved when duty cycle aligns with job demands.

- You’ll avoid surprise shutdowns and lost time.

- You’ll gain confidence in energy forecasts.

- You’ll reduce unnecessary power draw.

- You’ll protect equipment lifespan through proper power management.

Calculating Electricity Costs for Welding

Now that you’ve matched duty cycle to job demands to limit wasted run-time, you can turn attention to quantifying what that run-time actually costs.

Calculate on-arc energy by measuring operating kW: typical arc welding draws about 5–7 kWh when active, and many machines range 5–15 kWh. Multiply on-arc kW by actual welding hours per billing period to get kWh consumed.

Measure on-arc kW (typically 5–15 kW) and multiply by actual welding hours to calculate kWh consumed.

Apply your utility rate for a straightforward cost analysis: e.g., 9.6 kWh/week at $0.15/kWh equals roughly $6.19/month. Include only active welding time; idle draw is minimal and usually negligible in monthly totals.

For higher-amp, high-duty-cycle tasks, expect proportional increases in kWh and cost — incorporate those runs into your estimate. Use welding efficiency (machine and process) to refine estimates: more efficient transfers reduce required welding time and kWh per weld.

Track actual run-time and bills for calibration so your cost analysis reflects real-world use rather than theoretical maxima.

Factors That Change Welding Power Consumption

Although several variables interact to determine a welder’s power draw, you can generally predict consumption by focusing on amperage, process type, duty cycle, and material properties.

You’ll see most machines draw 5–15 kWh in operation; extremes run 1–50 kWh. Higher amperage for greater material thickness raises instantaneous power, and a higher duty cycle increases energy consumed over time.

Different welding techniques matter: TIG tends toward 3–5 kWh while MIG commonly uses 6–10 kWh. Machine efficiency and control electronics alter real-world consumption; modern units often reduce losses.

Material composition also affects required heat input—denser metals need more energy to reach penetration. When estimating costs, convert amperage and duty cycle into average kW, then multiply by hours used.

- You’ll feel reassured when calculations match reality.

- You’ll appreciate predictable energy ranges.

- You’ll worry less about surprises in bills.

- You’ll gain confidence selecting processes.

- You’ll respect the impact of material thickness.

Energy-Saving Practices and Equipment Options

When you optimize equipment and procedures, welding energy use drops noticeably: choose efficient TIG machines (3–5 kWh ranges) for detailed work, keep gear serviced to prevent power losses, and set amperage to match material thickness so you don’t overheat parts.

You should prioritize energy efficient machines with digital controls and inverter technology; they deliver higher arc stability at lower input power and reduce idle consumption.

Implement targeted maintenance practices — calibrated meters, clean cooling channels, tight electrical connections, and scheduled consumable replacement — to preserve efficiency and prevent drift that increases draw.

Adjust process parameters: lower amperage, optimized duty cycles, and correct travel speed reduce cumulative kWh per joint.

Consider retrofit options such as power factor correction devices to cut reactive power and lower utility charges.

When you combine modern equipment selection, disciplined maintenance practices, and parameter tuning, welding operations consume measurably less electricity and produce predictable, reproducible cost savings.

Comparing Electric Welding to Other Power Sources

When you compare electricity to diesel or propane for welding, electricity usually gives lower operating costs per hour—most commercial electric welders draw about 2,000–4,000 W versus fuel consumption and maintenance for engine-driven units.

You’ll trade portability and sustained high-output capability for the lower noise, simpler upkeep, and minimal standby draw of electric machines.

Assess jobsite power availability and required duty cycle to decide whether lower energy cost or mobile power density is the priority.

Electricity vs. Fuel Costs

How much will welding add to your operating costs? You’ll find electric consumption typically runs 5–15 kWh/hour, and at $0.10–$0.15/kWh that translates to low per-hour and monthly expenditures (roughly $6.19/month based on 9.6 kWh/week).

Electric welders draw minimal idle power, so your duty-cycle governs cost. By contrast, gas or diesel units expose you to volatile fuel prices and storage overhead, reducing effective fuel efficiency.

- You’ll breathe easier with predictable monthly bills.

- You’ll avoid surprise fuel price spikes.

- You’ll appreciate lower idle parasitic draw.

- You’ll reduce logistical headaches around fuel storage.

- You’ll see welding costs stay small relative to other workshop loads.

Portability and Power Tradeoffs

Although electric welders deliver quiet, efficient operation for shop work, they tie you to a reliable electrical supply and heavier infrastructure that can limit field mobility.

You’ll weigh electric welder portability against performance: typical machines consume 5–15 kWh and high-end units can exceed 7,800 W, requiring substantial cabling and sometimes generator support.

In a power source comparison, gas or diesel systems offer true remote capability because they don’t depend on mains power, though they demand ongoing fuel and maintenance costs.

Electric units give lower operational cost and better energy efficiency—modern designs reduce consumption versus many fuel-based alternatives—but expect higher initial setup costs for onsite electrical upgrades.

Choose based on site access, total cost of ownership, and mobility needs.

Real-World Examples of Welding Energy Use

Because duty cycle and machine type directly affect consumption, you’ll see wide variation in real-world welding energy use: typical machines draw 5–15 kWh during operation, TIG units tend toward 3–5 kWh while MIG welders run about 6–10 kWh, and a 50 A welder at 230 V will pull roughly 11.5 kW under full load.

You can calculate costs by multiplying kW by hours and your rate; a 15 kW 3-phase unit running 20 minutes monthly consumes about 740.5 kWh annually when duty cycle is high, so monitor runtime closely.

Using efficient welding techniques and specifying energy efficiency in machine selection reduces consumption. Many hobbyists report only modest bill increases (~$6.19/month) with moderate use, while industrial shops see substantial draws.

Efficient techniques and energy-smart machine choices cut consumption—hobbyists see small bill bumps, shops face larger draws.

Base decisions on measured runtime, duty cycle, and process (TIG vs MIG). Balance task requirements, cycle length, and machine efficiency to optimize energy and cost without compromising weld quality.

- Pride in doing precise, efficient work

- Frustration at unexpected high bills

- Confidence from measured savings

- Concern over heavy-duty usage

- Satisfaction with optimized processes

Frequently Asked Questions

Can Welding Machines Be Powered by Solar Panels?

Yes — you can: picture panels glinting on a roof feeding an inverter and battery bank. You’ll need high solar panel efficiency and verify welding machine compatibility, system sizing, and duty cycle to guarantee reliable, safe operation.

Does Welding Increase Home Insurance Premiums?

Yes — if you weld at home without proper welding safety measures, your insurer may raise premiums or deny insurance coverage; you should disclose activities, document precautions, use certified equipment, and consult your broker to avoid surprises.

Are Battery-Powered Welders as Strong as Mains Welders?

Like a thunderbolt in your toolbox, you’ll find battery-powered welders can match mains for many tasks. You’ll compare battery performance and power comparison specs: duty cycle, amperage, and efficiency determine whether they’re equally capable.

Does Welding Produce Electrical Interference With Electronics?

Yes — welding can cause electrical interference with electronics. You’ll generate welding interference (EMI/RFI) that can upset nearby electronic devices; you should shield sensitive gear, increase distance, use grounded cables, and apply filters or ferrites.

Can Welding Skills Reduce Overall Electricity Consumption?

By mastering skill applications, you’ll cut wasted arcs and preheat time, improving energy efficiency; you’re basically a steely-time tinkerer — you’ll lower consumption through technique, equipment tuning, and consistent parameters for predictable power use.

Conclusion

You’ve seen how welders draw power like different-sized engines—MIGs and stick welders roar with higher amps, TIGs sip more precisely, and duty cycle limits the pulse of energy. Think of electricity as the weld pool’s heartbeat: control it, and you steady the arc and the bill. Apply duty cycles, efficient machines, and good technique, and you’ll trim consumption without sacrificing quality—practical steps that keep your shop’s lights steady and costs predictable.