Expect to pay roughly $5,000–$30,000 for NWTI-style welding training depending on program type, length, and what’s included. Short, intensive certificates cost more per month but finish in 3–12 months; community-college tracks run lower overall with extra general ed. Factor in $100–$500 per PPE item, tools, and possible consumable fees. Look for scholarships, payment plans, and whether labs supply wire or you must. Keep going to see detailed breakdowns and saving tactics.

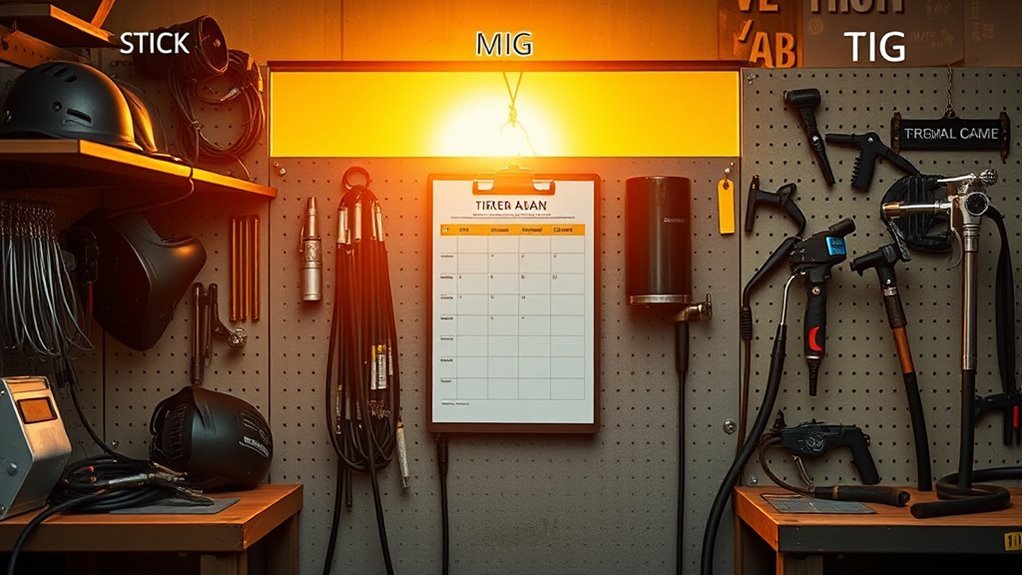

Tuition Breakdown by Welding Program Type

One clear way to budget for welding training at Northwest Technical Institute (NTWI) is to match program depth to your goals: certificate and community-college–level programs generally run $5,000–$15,000 and deliver broad hands-on fundamentals.

Specialized trade-school programs average $15,000–$30,000 for intensive technique and certification prep, and online options cost $200–$4,000 for flexible, theory-focused instruction.

Remember to add the cost of safety gear, tools, and textbooks, which can materially increase your total outlay.

You should evaluate welding program types by expected competencies, contact hours, and credential value. Tuition variations reflect instructor ratios, lab access, and certification exam prep.

Compare program syllabi, graduation outcomes, and licensure alignment so you can prioritize cost against employability and skill depth.

Fees for Tools, Safety Gear, and Supplies

Beyond tuition and program type, you’ll also face out-of-pocket charges for the gear and consumables that let you practice welding skills safely and to industry standards.

You’ll budget for safety gear that ranges from about $100 to $500 per item—helmets, jackets, gloves, boots—and consider buying your own welding machines and hand tools, which materially affect total cost.

Supplies like wire may be provided or require separate purchase. Invest in durable equipment; it lowers lifecycle cost and meets trade expectations.

- Personal protective equipment: helmets, jackets, gloves, boots (budget $100–$500 each)

- Portable welding machines and essential hand tools

- Consumables: wire, tips, electrodes (program may supply some)

- Contingency: replacement parts, maintenance, and living expenses when relocating

Lab Access, Equipment Use, and Material Costs

Although tuition covers lab access at Northwest Technical Institute, you’ll still need to supply your own certified safety gear and in some cases specific portable machines or hand tools required by the curriculum.

Tuition grants shop access, but students must provide certified PPE and any required portable tools or machines.

You’ll use NTWI’s well-equipped shops for hands-on training, but personal PPE ($100–$500) and any mandated portable welders remain your responsibility. Confirm whether consumables like wire and electrodes are included per course; if not, budget separately.

Observe strict lab safety protocols and document equipment maintenance routines for assigned stations — failure to do so can restrict access.

NTWI’s quality lab assets represent a long-term professional investment, so treat shared machines with care, report faults immediately, and follow scheduled maintenance to protect your training continuity and reduce unexpected replacement costs.

Financial Aid, Scholarships, and Payment Plans

You’ll evaluate NTWI’s financial aid options, including federal and state grants and program-specific scholarships, to determine which cover welding tuition and fees.

Review available payment plan choices to spread costs across the program term and compare terms, deposits, and installment schedules.

Check application deadlines and eligibility criteria so you can maximize grant and scholarship awards before you enroll.

Financial Aid Options

Wondering how you’ll afford welding training at NTWI? You’ll get targeted guidance to build financial literacy, verify grant eligibility, and select the best aid mix.

NTWI’s advisors walk you through federal and state grants, scholarship criteria, and external vocational funding so you can craft a cost plan that matches program requirements.

- Federal and state grants: determine eligibility, complete FAFSA, and document need.

- Scholarships: review merit and need-based awards specific to welding programs.

- Local/state vocational programs: pursue employer, union, or community funding opportunities.

- NTWI resources: attend information sessions, access application checklists, and get timeline support.

You’ll leave with a practical funding roadmap that minimizes out-of-pocket expense and optimizes available aid.

Payment Plan Choices

How will you structure payments to keep welding training affordable and predictable? You’ll combine financial aid, scholarships, and NWTI’s payment plans to manage costs.

Start by applying early for federal and state grants and local or trade-association scholarships; deadlines and limited funds make timing critical. Contact admissions or check the NWTI website to identify eligible awards and application steps.

If grants and scholarships don’t cover full tuition, enroll in NWTI’s flexible payment plans to spread installments across the program term, reducing lump-sum strain. Track disbursements and plan monthly obligations to maintain payment flexibility.

Develop basic financial literacy—budgeting, tracking aid, and reconciling statements—so you can optimize aid use and avoid missed payments.

Short Courses and Continuing Education Pricing

Because short courses and continuing education cover varied topics and lengths, their pricing at Northwest Technical Institute reflects each course’s focus and duration and can differ from the Basic Welding Class rate.

You’ll find the short course benefits and continuing education advantages are tied to modular formats, targeted skills, and optional certification paths. Costs vary to cover instruction, materials, and any exam fees.

- Fees scale with course length and technical depth, so expect variable tuition.

- Materials and lab consumables may be itemized separately from tuition.

- Certification exams or specialty assessments can add a one-time charge.

- Safety gear costs typically range $100–$500 per item and may be required.

You’ll choose courses based on precise needs and budget constraints.

Cost Comparisons: Community College Vs Trade Programs

When comparing community college and trade program costs, you should weigh tuition and required fees against the hands-on training you’ll receive.

Community colleges typically charge $5,000–$15,000 for longer associate programs that can include business and financial aid options, while trade schools run $15,000–$30,000 for shorter, skills-focused certificates.

Factor program length into value assessments—shorter trade programs get you into the workforce faster, but longer community college programs may offer broader credentials and funding flexibility.

Tuition and Fees

Compare your options by looking beyond the sticker price: community college welding programs typically run $5,000–$15,000, while trade schools concentrate on specialized technique training and often cost $15,000–$30,000.

You’ll track tuition trends and program affordability to judge true cost versus outcome. Community colleges usually bundle broader coursework — sometimes business management — increasing curricular value; trade schools charge a premium for concentrated hands‑on technique.

Online modules exist at $200–$4,000 if you need flexible, lower‑cost theory.

- Factor in mandatory PPE, tools, and consumables.

- Estimate living and transportation for on‑site labs.

- Compare credit transferability and credential recognition.

- Weight instructional hours per dollar for cost‑effectiveness.

Use this technical cost breakdown to make a pragmatic enrollment decision.

Program Length & Value

Program length directly shapes the value you get per dollar: community college welding tracks often span 1–2 years for certificates or associate degrees, delivering broader coursework and lower per-term tuition ($5,000–$15,000).

In contrast, trade schools compress intensive, skill-focused training into 3–12 months with higher upfront costs ($15,000–$30,000) but more lab hours per week.

You should weigh program benefits against time and cost: longer community college programs add general education and potential business-management modules that support career advancement and mobility.

Meanwhile, shorter trade programs prioritize welding throughput, specialized techniques, and small-class, equipment-rich labs for rapid employability.

Choose based on whether you need depth and credentials or concentrated, hands-on skill acquisition to enter the workforce quickly.

Budgeting Tips and Cost-Saving Strategies

If you want to keep welding training affordable, start by mapping out all program and equipment expenses so you can prioritize what’s essential and what can wait.

Use budgeting strategies and a rigorous cost analysis to compare programs from community colleges ($5,000–$15,000) to private schools ($5,000–$30,000).

Factor in safety gear ($100–$500 per item) and recurring material costs when forecasting cash flow.

Seek scholarships, local grants, and reduced-tuition vocational options to lower upfront burden.

Buy durable PPE to reduce replacement frequency.

- Compare program inclusions and hidden fees before committing

- Prioritize high-quality safety gear over cheaper, short-lived alternatives

- Apply for trade-specific scholarships and financial aid early

- Consider local vocational or community-college routes for lower tuition

Frequently Asked Questions

What Certifications Do Graduates Qualify for After Completing NWTI Welding Programs?

You’ll earn certification types like AWS D1.1, SMAW/GMAW/GTAW process certificates and NCCER credentials, demonstrating compliance with industry standards and practical code-related qualifications for structural, fabrication, and pipe welding in professional settings.

Are There Job Placement or Apprenticeship Assistance Services Available?

Yes — you’ll get job placement support and connections to apprenticeship programs; we’ll provide resume review, interview prep, employer introductions, and technical placement matching so you can shift directly into paid apprenticeships or entry-level welding roles.

What Are Class Sizes and Instructor-To-Student Ratios in Welding Labs?

You’ll typically find welding class sizes of 8–16 students with instructor ratios of 1:6 to 1:10, ensuring hands-on supervision, safety compliance, individualized feedback, and efficient equipment use for skill development in practical lab settings.

Is Housing or Local Accommodation Assistance Offered for Out-Of-Town Students?

Yes — you’ll get housing options and student support; we’ll coordinate local accommodation referrals, vetted listings, and short-term dorm or homestay placements, provide arrival logistics, and maintain a point person for any housing-related issues or adjustments.

Can Employers Sponsor or Reimburse Tuition for Enrolled Students?

Yes — you can pursue tuition assistance; many employers offer employer sponsorship or tuition reimbursement programs, so check eligibility, submit required documentation, coordinate billing with the school, and confirm whether sponsorship covers exams, materials, or prorated fees.

Conclusion

You’ll balance tuition spreadsheets against the heat of the torch: one column lists predictable fees, the other the unexpected burn of consumables. You’ll choose programs with clear lab access and durable tool lists, not shiny promises. Use scholarships, payment plans and bulk-buy supplies to convert variability into predictable cost per hour. With technical rigor and practical discipline, you’ll plan like an engineer and spend like a foreman, keeping quality high and surprises low.