You’ll usually pay between about $3,000 for a short certificate and $20,000+ for advanced or degree-level welding programs, with most students spending roughly $5,000–$15,000 once supplies, PPE and fees are included. Community colleges tend to be cheaper than private trade schools, and apprenticeships or employer-sponsored training can cut costs further. Expect extra expenses for tools, testing and living costs. Keep going and you’ll get specifics on program types, aid and ROI.

Typical Price Ranges for Welding Programs

Expect to pay a wide range for welding training: most programs fall between $5,000 and $15,000, though advanced tracks can top $20,000.

You’ll see certificate courses from about $3,000 to $10,000, diplomas typically $5,000–$15,000, and associate degrees roughly $10,000–$25,000 depending on institution and location.

Community college options often sit at the lower end, around $5,000 for two-year programs.

Don’t forget additional expenses: equipment, materials, and living costs can add $500 to $15,000.

When you run welding school comparisons, break costs into tuition, supplies, and living to spot real differences.

Use that breakdown for financial planning so you know upfront what you’ll need and can compare true total cost efficiently.

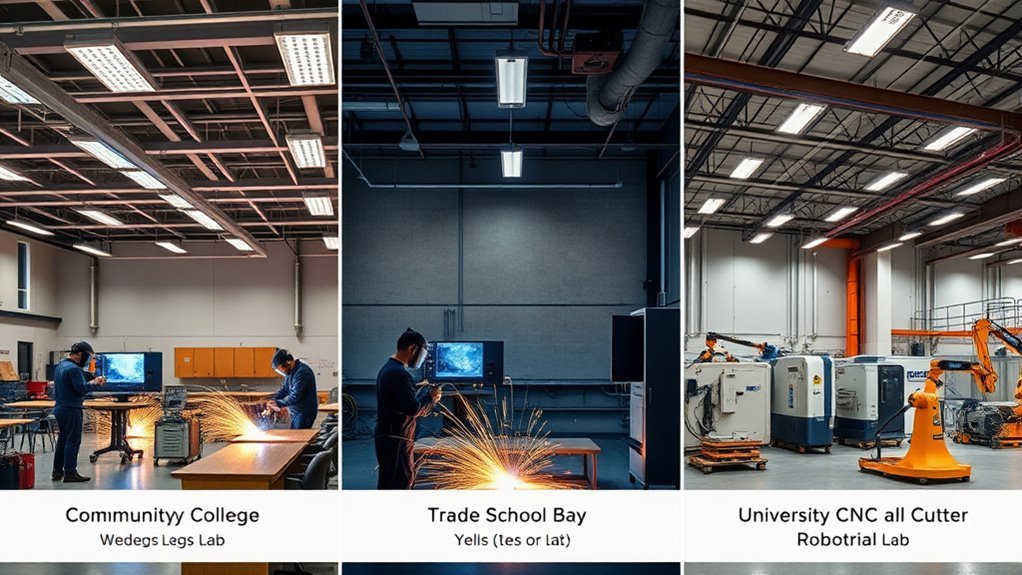

Types of Schools and How They Affect Cost

Because the type of school you choose determines both the training style and the price tag, it’s important to compare options before you enroll.

You’ll find trade schools focus on hands-on vocational training, with welding school tuition typically between $5,000 and $20,000; that higher per-program cost often buys intensive shop time and industry connections.

Community colleges offer a lower-cost path — around $5,000 for a two-year program — and include general education classes.

Community colleges provide an affordable two-year option (about $5,000) and include general education alongside technical training.

Certificate programs run $3,000 to $10,000 for shorter, skills-focused courses.

Advanced associate or bachelor programs climb higher, reflecting longer study and broader curricula.

For an accurate cost comparison, factor in equipment, materials, and living expenses, which can add $5,000–$15,000 per year.

Program Lengths: Certificates, Diplomas, and Degrees

You’ll choose between short certificate courses that run weeks to months, one-year diplomas, two-year associate degrees, or even four-year bachelor’s tracks depending on your goals.

Certificates get you into the shop fastest and cheapest, diplomas and degrees add broader training and higher tuition over longer timelines.

Compare program length, hands-on hours, and whether general education is included so you can match cost to the credential you want.

Certificate Program Duration

Certificate-level welding programs typically run from a few weeks to several months, making them the quickest route to hands-on skills and entry-level work.

You’ll appreciate the program flexibility: accelerated tracks let you focus on core welding processes, while specialty short courses target techniques like TIG or pipe welding.

Because these certificates concentrate on practical skill acquisition, you’ll spend most time in the shop rather than in general-education classes.

Costs for these short programs generally range from $3,000 to $10,000, and some trade schools offer specialized certificates under a year that keep expenses and time commitment low.

If you need rapid entry into the workforce or to add a specific credential, certificates give clear, measurable competence in a short span.

Degree & Diploma Timelines

If you need more extensive training or longer-term career options than short certificates offer, consider diploma and degree programs that expand both skill depth and credentials.

You’ll weigh diploma advantages like focused, one-year trades training against degree requirements that demand more coursework and time. Typical timelines and costs vary by school type:

- One-year diplomas: practical shop hours, tuition roughly $5,000–$15,000, faster entry to industry.

- Two-year associate degrees: broader theory plus credentials, tuition about $10,000–$25,000, better for supervisory roles.

- Four-year bachelor’s degrees: include business/engineering, tuition $40,000–$100,000, suited for management or engineering pathways.

Choose based on your career goals, budget, and how much classroom versus hands-on time you want.

Required Tools, Gear, and Additional Materials

You’ll need to plan for personal protective equipment, basic hand tools, and larger machines that aren’t always covered by tuition.

Expect PPE and small supplies to run roughly $100–$500, tools and welding machines to range from $500 up to $2,000, plus books and course materials that can add another $100–$500.

Also budget for certification test fees of about $300–$550 each so you’re not caught off guard.

Essential Personal Protective Equipment

Safety gear is nonnegotiable when you start welding, and you’ll want to budget for gloves, safety glasses, welding hoods, and other PPE that together typically cost $100–$500.

You’ll follow safety regulations from day one, so invest in certified items and keep a simple gear maintenance routine to extend life and performance.

Expect schools to either require your PPE or offer kits.

- A sturdy pair of leather gloves with gauntlets — protects from heat and spatter.

- Auto-darkening welding hood — protects eyes and face, usually the biggest single PPE cost.

- Safety glasses and ear protection — for grinding and nearby operations.

Plan on $100–$500 for PPE; total protective costs with extras often reach $500–$1,500.

Tools, Machines, and Supplies

Now that you’ve got your PPE sorted, expect to add a set of tools, machines, and consumables to your budget; these items let you practice outside class and meet program requirements.

Plan on $500–$1,500 for hand tools, chipping hammers, clamps, gauges, and replacement consumables. If your program requires a personal welding machine, budget $500–$2,000; choose equipment that matches your course processes and includes service support.

Add $100–$500 for filler rods, wire, tips, and shielding gas during training cycles. Factor in certification test fees of $300–$550 per exam and living expenses of $5,000–$15,000 annually.

Focus on welding tool selection for durability and on machine maintenance to extend service life and avoid unexpected costs.

Certification and Testing Expenses

Because certification testing usually isn’t included in tuition, you should budget separately for exam fees that typically run $300–$550 each, with specialized tests (like underwater welding) costing more.

You’ll want to confirm testing prerequisites with your program—completing coursework often makes you eligible for AWS exams. Certification benefits include clearer hiring paths and higher pay, so view fees as an investment.

Confirm testing prerequisites with your program—completing coursework often qualifies you for AWS exams; certifications open hiring paths and higher pay.

- Visualize scheduling a $400 AWS practical and a $350 written test over two days.

- Picture adding preparatory tack-time or a retest fee if you need more practice.

- Imagine paying extra for specialty endorsements (higher-cost exams, travel, or equipment).

Plan for test fees, possible retakes, and specialty surcharges when you set your budget.

Financial Aid, Scholarships, and Payment Plans

If you’re worried about upfront costs, federal grants, low‑interest loans, scholarships from professional groups (and some schools like MTI), plus flexible payment plans can make welding training affordable.

You can apply for federal aid to lower tuition, and low‑interest loans bridge gaps when grants don’t cover everything. Look for scholarship opportunities from trade associations, private companies, and schools—MTI often targets high school seniors entering welding.

Ask the school about structured payment plans in 7‑ or 10‑week increments so you pay smaller, regular amounts. Some programs offer pay‑as‑you‑go plans without credit checks or interest, giving extra payment flexibility.

Remember to budget separately for certification test fees, typically $300–$550, which aren’t always included.

Apprenticeships and Employer-Sponsored Training

When you join an apprenticeship or employer‑sponsored training program, you’ll learn on the job while getting paid and often gain classroom instruction that counts toward certification. This makes it easier to shift into full‑time work once you complete the program.

You’ll get clear apprenticeship benefits: paid training, progressive wages, and direct hiring pathways. Employer obligations usually include covering tuition/materials or providing scheduled mentorship and wage increases tied to milestones.

- Picture yourself welding under a trainer’s eye, earning while you practice.

- Picture classroom nights that build code knowledge alongside shop time.

- Picture wage steps that rise as your skill level advances.

Choose programs where employer obligations are written and progression timelines are explicit.

Calculating Return on Investment and Earning Potential

Although upfront tuition can look steep—typically $5,000 to $15,000 and sometimes over $30,000 for advanced programs—you should weigh that against median wages (about $47,540 in May 2022), speed of entry into the workforce, and the premium you can earn with certifications and specialized skills.

Calculate ROI by comparing total program cost to first-year salary and expected time to recoup expenses; entry-level placement often shortens that horizon.

Factor in welding industry trends and job market analysis: demand in oil and gas, shipbuilding, and aerospace drives higher pay for certified specialists.

Project longer-term earnings growth with experience and niche qualifications, and include certification exam costs, tool purchases, and regional wage differences for a realistic financial picture.

Picking the Right Program for Your Budget and Goals

You’ve run the numbers on ROI and now need to match those projections to a program that fits both your budget and career aims.

Evaluate program length, credential type, and total cost — tuition plus materials and certification fees — so your projected earnings align with outlay. Community colleges often give lower tuition (~$5,000) for associate degrees; certificates cost $3,000–$10,000 and get you into the workforce faster.

Match program length, credential, and total cost—tuition plus materials and certification—so projected earnings justify the investment.

Factor in $500–$2,500 for gear and tests and explore scholarships or federal loans to lower debt.

- Short, cheap certificate for quick entry and basic skill development.

- Two-year associate for broader training and stable welding career growth.

- Apprenticeship or combo program for paid experience and certification.

Frequently Asked Questions

How Long Before I Can Get a Welding Job After Graduation?

You can often get a welding job within weeks to a few months after graduation if you’re proactive; complete certification programs, build job readiness through hands-on practice and portfolios, network with employers, and prepare for practical and safety assessments.

Are Welding Programs Available Online or Hybrid Formats?

You’ll be thrilled to learn online welding and hybrid programs exist: they mix virtual theory with hands-on labs at local shops or campuses, so you’ll get practical skill practice, scheduled shop time, instructor feedback, and credential pathways.

Do Welding Schools Assist With Job Placement or Internships?

Yes — many welding schools provide job placement and internship opportunities; they’ll connect you with employers, host career fairs, arrange apprenticeships, coach your resume and interviews, and follow up to help you secure work after graduation.

Can Prior Experience or Military Service Reduce Program Cost?

Yes—your prior experience can earn credits or waivers, and military benefits often fund tuition or provide GI Bill support. Check schools’ credit-evaluation policies and veterans’ offices to maximize reduced costs and available tuition assistance.

What Safety Risks Are Taught Beyond Basic PPE and Procedures?

Imagine a trainee who nearly lost a finger to molten spatter; you learn welding hazards beyond PPE: confined-space risks, fume exposure, fire control, electrical shock, ergonomics, and emergency response—safety training drills these scenarios and mitigation steps.

Conclusion

Welding school costs vary, but you can make smart choices that fit your budget and goals. Weigh program length, school type, tool and certification fees, and potential financial aid. Apprenticeships can cut costs while boosting experience. Think of your education as an investment—shop programs like you’d compare tools: focus on durability and value, not just price. Pick a program that balances upfront cost with the earning potential you want.