You can determine your welder’s electrical use by reading the dataplate for voltage and amperage, multiplying V×A to get volt‑amps, then dividing by 1,000 to convert to kilowatts. Adjust that figure for duty cycle and welding efficiency to estimate average input kW, multiply by actual run hours to get kWh, and apply your utility rate for cost. Use a clamp wattmeter for validation, and continue below to see practical examples and adjustment tips.

Why Knowing Your Welder’s Electrical Consumption Matters

Because operating costs hinge on energy use, you should know your welder’s electrical consumption to estimate project expenses accurately.

You’ll quantify voltage and current to calculate kilowatt draw, then multiply by runtime and local tariffs to produce precise cost figures. That data feeds energy management protocols: scheduling weld cycles during off-peak rates, reducing idling, and selecting more efficient processes.

Monitoring consumption identifies abnormal draws that signal maintenance needs or improper settings, enabling targeted interventions.

Monitoring unusual power draws flags maintenance issues or incorrect settings, allowing targeted fixes that prevent downtime and waste

Accurate electrical metrics support cost optimization by informing equipment selection, duty-cycle planning, and lifecycle budgeting.

You’ll therefore convert measured power data into actionable financial controls, lowering bills and raising profitability while maintaining welding performance and adhering to operational constraints.

Reading the Welder Dataplate: Voltage, Amperage, and Power

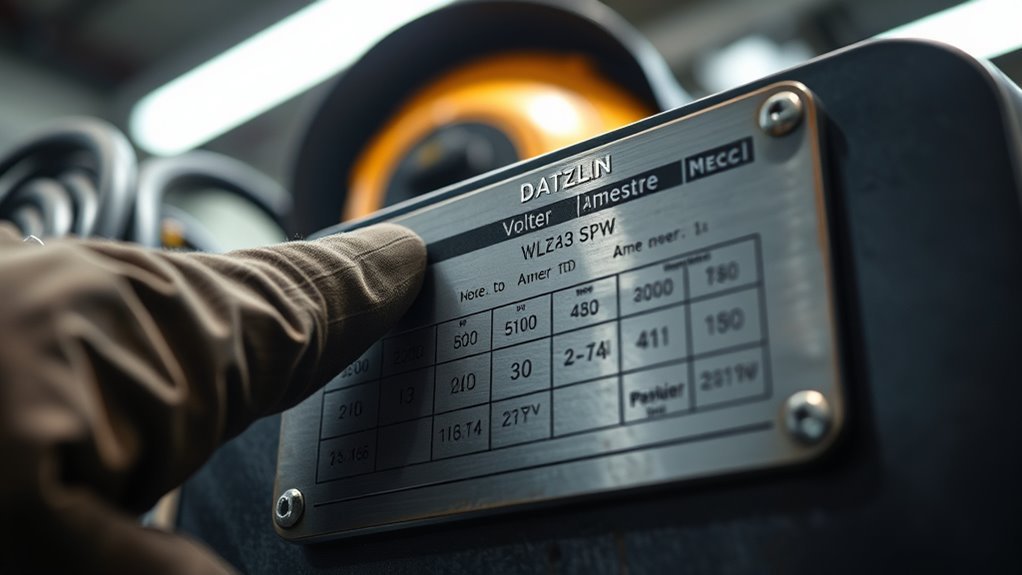

The dataplate on your welder is a compact technical summary you’ll consult before hookup and cost estimates, because it lists the machine’s rated voltage and amperage — the two parameters you need to compute its apparent power. Read dataplate details to locate voltage ratings (V) and amperage (A). Voltage expresses potential; amperage expresses current. Multiply V × A to obtain volt-amperes (VA). Use the dataplate example: 240 V and 250 A yields 11,280 VA. Verify whether ratings are per phase or for the entire unit; note duty cycle and any correction factors on the plate. Accurate reading prevents undersized feeders and incorrect breakers, and supports efficient, safe operation.

| Parameter | Example |

|---|---|

| Voltage (V) | 240 |

| Amperage (A) | 250 |

| Apparent Power (VA) | 11,280 |

| Duty Cycle | 60% |

Converting Volt-Amps to Kilowatts and Estimating Kwh Usage

Start by converting the welder’s volt-amps to kilowatts: divide the VA value by 1,000 (kW = VA / 1,000), so a 240 V, 250 A machine rated at 11,280 VA corresponds to about 11.28 kW.

Use this conversion technique: compute VA as Volts × Amps, then apply the 1,000 divisor for kW calculations.

To estimate kWh usage, multiply the resulting kW by hours of operation (for example, 11.28 kW × 1 hour = 11.28 kWh).

For cost estimation, multiply total kWh by your electricity rate (11.28 kWh × $0.12 ≈ $1.35).

Document runtime precisely; continuous operation yields proportionally greater energy and cost.

Apply these conversion techniques and kW calculations consistently for accurate, repeatable estimates.

Accounting for Efficiency, Duty Cycle, and Operating Factor

When you account for efficiency, duty cycle, and operating factor together, you translate a welder’s nameplate VA into realistic kW and kWh figures that reflect actual shop conditions.

You begin by applying welding efficiency to the input power: divide useful welding power by the machine efficiency percentage to get true input kW.

Next factor in duty cycle: multiply the machine’s rated output time fraction (percentage of a 10‑minute interval) to estimate average arc-on power during cycles.

Then apply the operating factor (OF) to convert arc-on time to shift-level utilization (typical OF 20–40%).

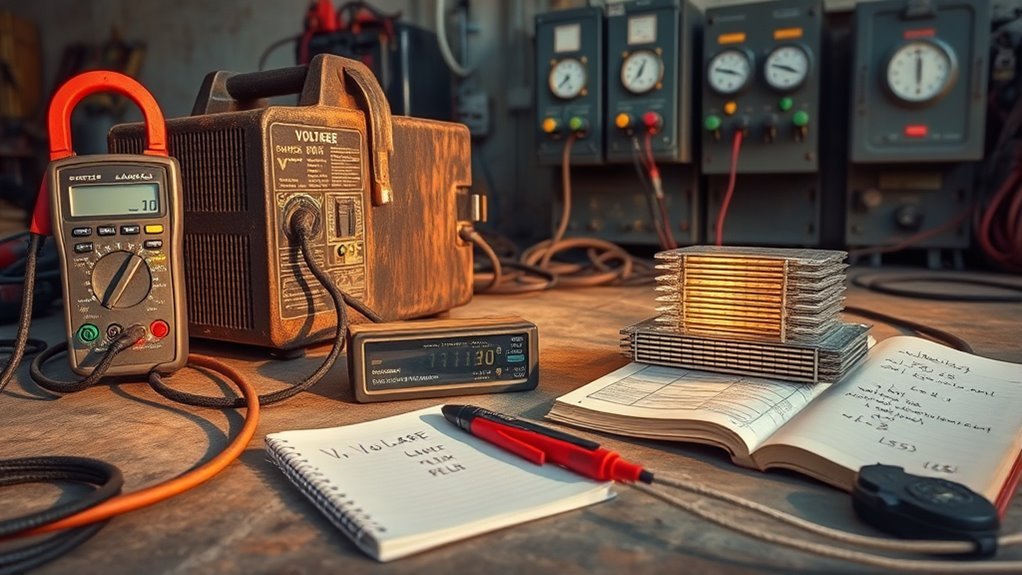

For highest accuracy, validate calculated draw with a wattmeter during representative welds. Record amperage and voltage during arc-on to reconcile calculated kWh with measured consumption.

Calculating Hourly and Project Electricity Costs

Costing out welding electricity is straightforward if you use the welder dataplate: multiply rated voltage by rated amperage to get volt‑amps (VA), divide by 1,000 to convert to kilowatts (kW), then multiply kW by your utility rate (for example, $0.12/kWh) and by the fraction of an hour the machine is actually drawing power to obtain dollar‑per‑hour and project costs.

Use that method to compute baseline hourly cost (e.g., 11,280 VA → 11.28 kW → $1.35/hr at $0.12/kWh). For project estimates, sum timed intervals at actual output levels (half capacity for 0.5 hr ≈ $0.68).

Record measured run-times to improve cost prediction and support electricity management decisions; update calculations with measured duty cycle and operating efficiency for greater accuracy.

Frequently Asked Questions

Do Different Welding Processes Change Electricity Rates Charged by Utilities?

Yes — utilities don’t usually vary rates by welding process, but you’ll see different electricity consumption. You’ll need to evaluate welding efficiency, duty cycle, and load profile so billing demand and time‑of‑use charges reflect actual usage.

How Do Standby Losses From Idle Welders Affect Monthly Bills?

Like a slow-dripping faucet, standby energy from idle welders quietly grows your bill: you’ll see idle consumption add fixed kilowatt-hours each month, so measure, isolate, and schedule shutdowns to cut costs and demand charges.

Can Solar or Battery Systems Power My Welder Efficiently?

Yes — you can. You’ll evaluate solar efficiency and battery capacity against your welder’s duty cycle, peak power, and surge current; design PV array, inverter and storage with margin, and include proper charge controllers and thermal management.

Should I Size My Shop Electrical Service for Peak or Average Welding Load?

Size for peak demand, not average load. You’ll calculate electrical capacity based on simultaneous welders, duty cycles, and inrush currents, apply diversity factors cautiously, and guarantee service, breakers, and busbar ratings meet peak requirements precisely.

Do Utility Demand Charges Apply to Sporadic Welding Operations?

Yes — like a sudden drumbeat, demand charges can apply to sporadic welding operations; you’ll be billed on peak kW, so measure instantaneous loads, shift welding timing, or use diversity strategies to lower recorded peaks and reduce charges.

Conclusion

You’ve traced the welder’s electrical heartbeat from dataplate to kilowatt-hour, and now you’ll put numbers to work like a machinist tightening the last bolt. Picture the meter spinning as you factor in voltage, amperage, efficiency, duty cycle and operating time — each variable a gear in the same clock. With precise conversions and methodical checks, you’ll transform opaque specs into predictable costs, keeping budgets steady and surprises grounded.