Yes — you’ll pay more up front and per joint to weld aluminum than to weld most plastics. Aluminum needs AC-capable TIG/MIG gear, shielding gas, specialized filler, and tighter torch consumables control, raising capital and consumable costs. It also requires longer training and higher labor rates, though welds deliver superior strength and longer service life. Plastics use low-cost hot-air or extrusion tools and cheaper prep, but slower throughput and lower joint strength. Continue for a deeper cost-versus-performance comparison.

Cost Drivers: Materials and Consumables

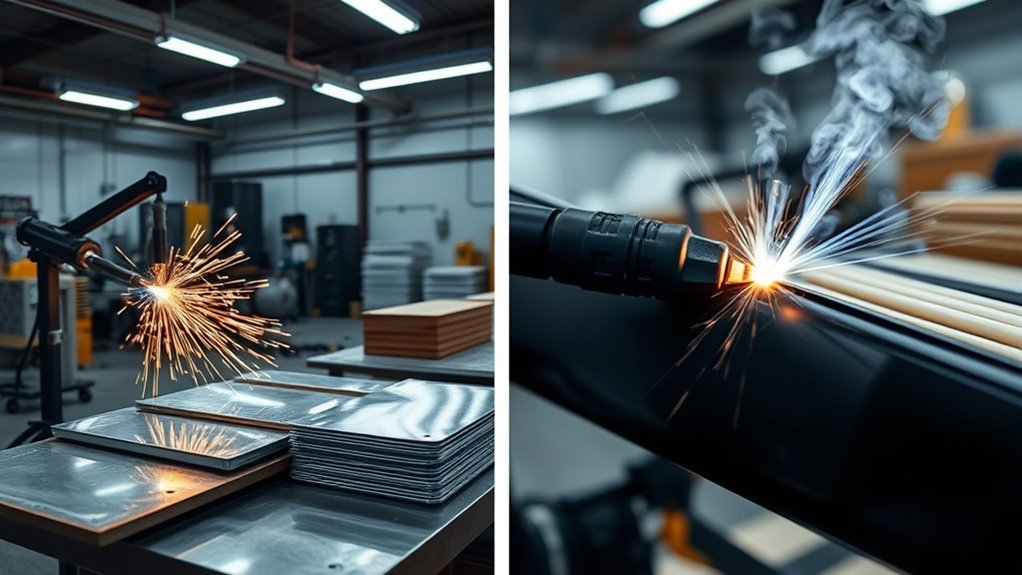

Equipment and consumables drive much of the cost gap between aluminum and plastic welding: aluminum welding typically demands pricier AC/DC TIG machines (often $2,000–$3,000) and specialized filler wires like 5356, plus straight argon and occasional spool-gun parts, while plastic welding can use tools under $100 with cheaper or no filler and no shielding gas.

You’ll see consumable costs concentrate in filler wire, torch consumables, shielding gas, and spool-gun wear for aluminum; these recur per job and scale with production.

Material compatibility adds inspection and prep time for aluminum—surface oxides and dissimilar alloys require cleaning and matched fillers—raising indirect costs.

Plastic welding reduces routine consumable spend and prep complexity, lowering per-joint cost and turnover time.

Equipment Requirements and Capital Investment

Because aluminum welding demands tighter control of arc characteristics and wire feed, you’ll face a substantially higher capital outlay than with most plastic welding setups.

You’ll need TIG or AC square-wave machines ($2,000–$3,000+), possibly spool guns or push-pull feeders, and high-frequency modules to stabilize the arc for clean aluminum joints.

By contrast, plastic welding often uses heat guns or hot-air welders costing from ~$50 upward.

By contrast, plastic welding commonly relies on simple heat guns or hot-air welders starting around $50.

These equipment choices reflect different welding techniques and their tolerances: aluminum demands precise current control and wire delivery, adding initial cost.

Also factor equipment longevity and maintenance: replacement parts and service for metal welding systems are costlier and more frequent than for basic plastic welders, increasing total capital tied to the toolset over its lifecycle.

Skill Level and Labor Costs

You’ll pay more up front for aluminum welding because training and certification programs are costlier and take longer to achieve proficiency.

Expect higher labor hour rates for certified aluminum welders—typically $20–$40/hr versus $15–$30/hr for plastic welders—which, combined with longer time-to-proficiency, raises lifetime labor spend.

Compare course costs, expected ramp-up hours, and prevailing wage rates to quantify the labor cost differential for your projects.

Training and Certification

While both aluminum and plastic welding require formal instruction, aluminum demands more specialized training and certification, which raises labor costs.

You’ll face stricter certification requirements and higher training costs for aluminum: courses can run from a few hundred to several thousand dollars and include theoretical exams plus practical assessments.

That intensity translates to longer, more technical programs and documented competencies employers require. As a result, you’ll pay higher hourly rates for certified aluminum welders and invest more time and money to reach hireable standards.

Economically, the up-front training outlay is offset by greater earning potential and market demand for qualified aluminum welders, but your immediate labor budget will be higher than for comparable plastic welding labor.

Time to Proficiency

How quickly you can become proficient depends heavily on the material: aluminum welding demands considerably more time and practice than plastic welding.

You’ll face a steeper learning curve with aluminum because it’s heat-sensitive and unforgiving of contamination. Technique mastery involves precise heat control, joint preparation, and maintaining a stable weld pool — skills that typically require formal training and extended hands-on practice.

Plastic welding has a lower barrier to entry and shorter skill ramp, so you can attain functional proficiency faster.

Because aluminum requires more time to master, you’ll incur higher upfront training and initial labor inefficiencies as you develop competence.

In procurement or staffing decisions, factor the prolonged technique mastery for aluminum when estimating long-term labor cost impacts and workforce development timelines.

Labor Hour Rates

Mastering aluminum welding takes longer, and that extended training directly affects labor hour rates you’ll face.

In the current labor market, aluminum welding rates typically run $75–$150/hour versus $50–$100/hour for plastic welding. You’ll pay more because aluminum demands TIG/MIG proficiency, tighter tolerances, and specialized equipment that lengthen job times and training cycles.

Skilled aluminum welders are scarcer, so supply constraints push rates up; plastic welding can often be handled by less specialized technicians at lower cost.

Regional variations matter: urban centers usually command premium rates compared with rural areas, altering project budgets considerably.

When you estimate costs, account for higher hourly rates, potential for longer task durations due to material handling, and equipment-driven time increases.

Process Speed, Efficiency, and Throughput

Because aluminum conducts heat rapidly and melts at a relatively low temperature, you can often weld joints faster than with many plastics. However, that speed comes with higher amperage demands and the need for specialized TIG or MIG setups that raise per-job costs.

Aluminum’s rapid heat conduction lets you weld faster than many plastics, but requires higher amperage and specialized TIG/MIG setups.

You’ll select welding techniques based on material properties and throughput targets: TIG offers precise control but lower deposition rates, while MIG increases speed with spool-fed wire.

In production, you’ll boost efficiency through automation and optimized fixturing, achieving higher cycle counts than manual plastic welding.

Plastics demand slower, controlled heating because of poor thermal conductivity and risk of distortion, reducing throughput.

Joint Strength, Durability, and Lifecycle Value

1 key advantage of aluminum welding is the higher strength-to-weight joints you get compared with most thermoplastics, and that advantage materially affects durability and lifecycle value.

You’ll find joint performance of welded aluminum consistently exceeds plastic welds because aluminum’s mechanical properties resist impact, fatigue, and environmental degradation.

In a material comparison, aluminum delivers longer service life and lower maintenance frequency, so your total lifecycle cost can be favorable despite higher upfront welding equipment and process expense.

When structural integrity is critical, aluminum welding provides predictable failure modes and greater resistance to temperature cycling than thermoplastics, which can creep or soften.

You should weigh initial capital outlay against reduced replacement and repair costs over the asset’s operational lifespan.

Common Applications and Industry Use Cases

You’ll see aluminum welding dominate structural and safety-critical parts like automotive body sections and aerospace components where strength-to-weight matters.

Plastic welding, by contrast, is common in bumper repairs, consumer appliances, and non-pressurized tanks where cost and speed outweigh high structural performance.

For industrial piping and storage tanks you’ll choose materials and methods based on chemical compatibility, pressure requirements, and lifecycle cost rather than raw equipment price alone.

Automotive Repairs and Bumpers

How do you choose between aluminum and plastic welding for bumper and body repairs?

You evaluate bumper types, damage severity, and structural role.

Plastic bumpers and trim respond to hot-air or extrusion welds—repair techniques that use lower-cost tools and are faster for cosmetic fixes.

Aluminum bumpers or reinforcements demand TIG or MIG processes, higher amperage machines, and experienced operators because heat control affects metallurgical integrity.

Equipment costs ($2,000–$3,000 for aluminum vs. low-cost plastic welders) and operator skill drive economics: plastic welding wins for minor impact repairs and rapid turnaround; aluminum welding is necessary when structural strength and crash performance are at stake.

In practice, you select plastic for panels and trims, aluminum for load-bearing components.

Industrial Piping and Tanks

In industrial piping and tank work, you pick aluminum when weight savings, strength and corrosion resistance matter, and plastics like HDPE or PVC when chemical inertness and cost-efficiency are primary requirements. You evaluate tank design and material compatibility: aluminum suits high-pressure, structural systems where MIG/TIG welding controls heat input; plastics suit chemical storage where hot-air or extrusion welding yields simple repairs and lower material cost. Equipment, joint integrity, and service environment drive choice. Aluminum has higher up-front welding equipment and filler costs; plastics reduce material and repair labor but limit pressure rating. Use the table to compare key trade-offs.

| Property | Implication |

|---|---|

| Weight | Aluminum lighter |

| Corrosion | Plastics inert |

| Pressure rating | Aluminum higher |

| Welding gear | Aluminum specialized |

Consumer Goods and Appliances

After comparing tanks and industrial piping, consider how the same material trade-offs play out in consumer goods and appliances where production volume, part function, and cost per unit dominate decision-making.

You’ll find aluminum welding used in appliances, automotive trim, and electronics where lightweight construction and corrosion resistance meet consumer trends favoring performance and longevity. Aluminum requires higher-capital equipment ($2,000–$3,000) but yields superior product durability for high-stress parts.

Plastic welding, common for containers, toys, and housings, offers minimal setup cost (budget options near $50) and faster cycle times, suiting mass production and lower unit cost.

You should weigh upfront investment against lifecycle expectations: choose aluminum when strength and durability justify expense, and elect plastic where cost sensitivity and rapid assembly govern design.

Repairability, Maintenance, and Long-Term Costs

Although aluminum welding demands higher upfront investment and ongoing service, it can still be cost-effective for high-stress or structural applications where metal properties justify the expense.

You’ll face higher initial equipment and consumable costs (TIG units, filler rods, shielding gas) and more complex repair techniques that require skilled labor.

Maintenance frequency is greater for aluminum rigs because AC/high-frequency components need regular inspection and occasional replacement to maintain weld quality.

Plastics offer simpler, quicker repairability with low-cost welders and fillers and typically no shielding gas.

Over the life cycle, aluminum may incur additional costs from corrosion protection and more frequent component servicing, while plastic systems often yield lower long-term maintenance and faster turnaround on repairs, reducing total operational downtime and labor expense.

Choosing the Right Method: Cost vs. Performance

Which method gives you the best return on investment depends on balancing cost drivers against performance requirements.

You’ll perform a cost analysis comparing equipment (AC TIG $2,000–$3,000 vs. lower-cost plastic welders), consumables (5356 filler wire vs. simple plastic rods or stainless mesh), labor skill premiums, and setup/time overhead.

For each application you’ll run a performance evaluation: required joint strength, environmental exposure, and acceptable failure modes.

Use a decision matrix weighting upfront capital, per-repair labor/time, and long-term maintenance costs.

For small, nonstructural repairs, plastic welding typically minimizes total cost.

For load-bearing or automotive structural needs, aluminum welding’s higher expense is justified by superior mechanical performance.

Choose the method that meets your quantified performance thresholds at the lowest lifecycle cost.

Frequently Asked Questions

Can Aluminum and Plastic Be Welded Together Directly?

No, you can’t directly weld aluminum to plastic; you’ll need specialized welding techniques or intermediate materials because material compatibility differs, so you must analyze thermal, chemical, and mechanical interfaces and select adhesives, inserts, or hybrid joining methods.

How Do Environmental Regulations Affect Welding Costs?

Environmental regulations increase welding costs by requiring emissions controls, waste disposal, monitoring, and documentation; you’ll factor environmental impact assessments and regulatory compliance training into bids, raising labor, equipment, and permitting expenses across aluminum and plastic welding.

Are There Safety Differences Between Aluminum and Plastic Welding?

Think of a quiet storm: yes, safety differs—aluminum yields metallic welding fumes and intense heat, while plastic emits toxic vapors; you’ll use specific safety gear, ventilation, and procedures tailored to each material’s hazards and controls.

Can Welding Methods Affect Product Recyclability?

Yes — welding methods can affect recyclability: you’ll gain recyclability benefits when choosing techniques that preserve material properties, minimize contamination and facilitate disassembly, enabling cleaner streams, higher recovery rates, and more efficient downstream processing.

Is Post-Weld Finishing (Painting/Coating) Costlier for Either Material?

Post-weld finishing is typically costlier for aluminum because you’ll need more surface prep for post weld durability; coating options like anodizing or specialized primers add expense, whereas plastics often accept simpler painting or overmolding.

Conclusion

When deciding between aluminum and plastic welding, you’ll weigh upfront equipment, materials, and skilled labor against long-term durability. Think of a welder I knew who fixed an aluminum heat exchanger that lasted 15 years—each repair cost was like paying rent; plastic fixes needed frequent renewals. With aluminum you pay more initially but get higher strength and longer life; with plastic you save early yet face recurring service and replacement costs. Choose by lifecycle value.