Resistance seam welding machines typically cost between $10,000 and over $100,000, depending on several factors like machine type, size, and advanced features. Standard models fall within the $10,000 to $50,000 range, while custom machines can exceed $100,000 based on specifications. Additionally, costs can vary considerably depending on if the machine is new, used, or refurbished. To understand the full scope of costs and considerations, it’s crucial to explore all aspects of these machines further.

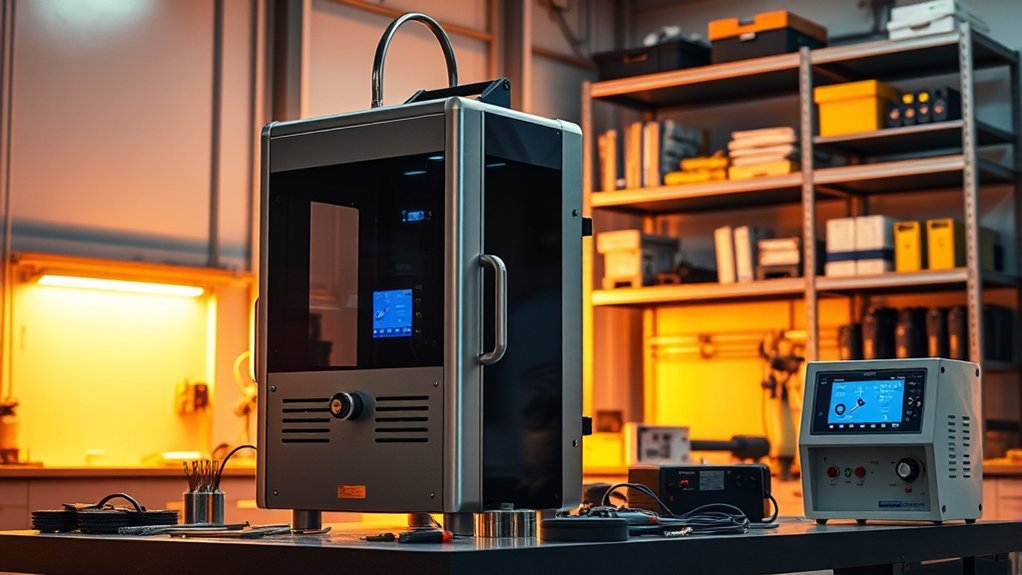

Overview of Resistance Seam Welding Machines

Resistance seam welding machines are essential tools in manufacturing, specifically designed for continuous welding applications. You’ll find these machines primarily used for joining metal sheets or strips, crucial in various processes. They operate by passing a high electrical current through the materials, generating heat at the weld interface, which results in a strong bond.

Available in several configurations, you can choose from standard press types to advanced XY or XYZ servo welders that enhance precision and efficiency. These options allow you to tailor the equipment to your specific production needs.

Choose from versatile configurations, including standard presses and advanced servo welders, to meet your unique production needs.

Maintenance and support services are crucial for these machines, as they help guarantee peak performance and extend the lifespan of your equipment.

Investing in a resistance seam welder means committing to a reliable system that can greatly boost your manufacturing capabilities while maintaining quality and consistency in your welded products.

Factors Influencing the Cost of Seam Welders

When considering a resistance seam welding machine, it’s crucial to understand the factors that influence its cost. Several key elements can greatly affect pricing:

- Machine Type and Size: The specific model and dimensions you choose can lead to substantial variations in cost, with larger and more specialized machines typically being pricier.

- Advanced Features: Custom configurations, such as automation options or multi-gun setups, add to the overall expense. Machines equipped with servo-driven systems for enhanced precision and efficiency also tend to be more expensive.

- Condition and Accessories: The choice between new, used, or refurbished machines impacts pricing. Additionally, don’t forget to factor in costs for necessary accessories, spare parts, and welding consumables, which can add to your budget.

Understanding these factors will help you make an informed decision when investing in a seam welder.

Price Range for Standard Seam Welding Machines

Standard seam welding machines generally fall within a price range of $10,000 to $50,000, influenced by various factors such as power rating, size, and design complexity.

Machines with higher power ratings or larger sizes typically command higher prices due to their enhanced capabilities. The complexity of design and features—like advanced control systems or automation—also affects the overall cost.

If you’re considering a more budget-friendly option, used or rebuilt machines can be considerably less expensive, often priced 30% to 70% lower than new models, depending on their condition and any upgrades.

However, keep in mind that while these options are cost-effective, they may lack the latest technology. For specialized applications requiring tailored configurations, the investment can rise, but standard machines generally remain within the $10,000 to $50,000 range, providing a solid foundation for various welding tasks.

Custom Seam Welding Machines and Their Pricing

For manufacturers looking to meet specific production needs, custom seam welding machines offer tailored solutions that can greatly enhance efficiency and output.

The pricing for these machines can vary widely, typically ranging from $20,000 to over $100,000. Several factors influence this cost:

Pricing for custom seam welding machines ranges from $20,000 to over $100,000, influenced by various factors.

- Specifications: The complexity and features you choose, such as automation capabilities or integration with existing lines.

- Material and Speed: The type of materials to be welded and the required production speed can considerably impact pricing.

- Advanced Features: Options like servo-driven systems or multi-gun configurations boost versatility, though they come at a higher price.

When considering a custom seam welding machine, it’s essential to request a detailed quote to grasp the complete pricing structure, including installation and support services.

This guarantees you make an informed decision that aligns with your production goals.

Additional Costs Associated With Seam Welders

While considering the purchase of a seam welder, it’s important to account for additional costs that can greatly affect your overall budget.

Installation expenses can vary considerably based on setup complexity and site-specific requirements. Regular maintenance and repair are vital for peak performance, so factor in these ongoing costs.

Consumables like electrodes and welding tips also contribute to your operating expenses, as they require periodic replacement.

Don’t overlook training costs for operators, particularly if your team is new to resistance welding technology; effective training helps maximize machine efficiency and safety.

Finally, shipping costs can be substantial, especially for larger machines, depending on your location and the chosen shipping method.

Comparison of New vs. Remanufactured Machines

When you compare new and remanufactured resistance seam welding machines, consider the significant differences in initial investment costs, which can impact your budget.

You’ll also need to evaluate ongoing maintenance and support expenses, as new machines may provide better service options and reliability.

Finally, assess the longevity and performance of each option to determine which aligns best with your operational needs.

Initial Investment Differences

Investing in a resistance seam welding machine requires careful consideration of the initial costs associated with both new and remanufactured options.

Here’s a breakdown of the key differences:

- Price Range: New machines typically range from $15,000 to $50,000, while remanufactured units can be 30-50% cheaper, making them budget-friendly.

- Technology and Performance: Remanufactured machines often include updated technology through extensive refurbishment, maintaining performance without the new price tag.

- Warranty and Configuration: New machines usually come with warranties and support services, but custom configurations can increase costs.

Remanufactured machines often offer standard options at lower prices, appealing to basic needs.

Maintenance and Support Costs

Understanding the long-term financial implications of maintenance and support costs is essential for making an informed decision between new and remanufactured resistance seam welding machines.

New machines generally come with extensive warranties and support packages, minimizing initial maintenance expenses. In contrast, remanufactured machines may lack such warranties, leading to unpredictable costs.

Additionally, they often require more frequent maintenance due to prior usage, potentially escalating long-term support costs. Spare parts for new machines tend to be more readily available and compatible with advanced technology, ensuring smoother operations.

Regular maintenance schedules are easier to establish for new machines, providing predictable budgeting, while remanufactured units may introduce variable expenses.

Ultimately, investing in a new machine can enhance efficiency and reduce downtime.

Longevity and Performance Factors

While evaluating the longevity and performance factors of resistance seam welding machines, you’ll find that new models generally outperform their remanufactured counterparts due to advancements in technology and design.

Here are some key considerations:

- Lifespan: New machines can exceed 10 years with proper maintenance, while remanufactured units may have a shorter lifespan based on their prior condition.

- Technology: New models often feature advanced automation, enhancing welding speed and energy efficiency compared to older remanufactured machines.

- Cost vs. Maintenance: Although remanufactured machines offer 30-50% savings, they may require more frequent servicing, impacting overall performance and uptime.

Investing in a new machine can yield better longevity and reduced operational costs in the long run.

The Role of Specifications and Capabilities in Pricing

Specifications and capabilities play an essential role in determining the cost of a resistance seam welding machine. Factors like power rating, size, and automation greatly influence pricing. For instance, machines built for high-volume production or advanced automation feature enhanced complexity, resulting in higher costs. Custom configurations tailored to your specific needs can also elevate the price.

Here’s a quick overview of how different specifications impact costs:

| Specification Type | Cost Impact |

|---|---|

| Standard Machine | $3,000 – $10,000 |

| Advanced Automation Features | $10,000 – $50,000 |

| Customized Configurations | $15,000+ |

Additional features, such as integrated servo systems, can further increase pricing. While used or remanufactured machines may be budget-friendly, their condition and specifications will dictate their overall value compared to new models.

Requesting Quotes From Manufacturers and Distributors

How can you guarantee you’re getting the best price for a resistance seam welding machine? The key lies in requesting quotes from various manufacturers and distributors. Here’s how to approach it effectively:

- Detail Your Needs: Clearly specify your welding application, production volume, and any custom configurations. This helps manufacturers tailor their quotes to your requirements.

- Consider All Costs: When asking for quotes, inquire about additional expenses such as shipping, installation, and support services. This assures you understand the total investment.

- Compare Multiple Offers: Gather quotes from different suppliers to identify competitive pricing. This comparison can lead you to the best equipment that fits both your budget and operational needs.

Importance of Considering Support Services and Repairs

When evaluating quotes from various manufacturers and distributors, it’s essential to also consider the support services and repair options they offer. These factors can notably impact your equipment’s lifespan and performance, minimizing costly downtime. Regular maintenance and timely repairs are vital to avoid issues from wear and tear, ultimately saving you money.

| Support Services | Benefits | Considerations |

|---|---|---|

| Spare Parts Availability | Quick repairs | Check local stock levels |

| Operator Training | Reduced operational errors | Assess training programs |

| Extensive Support | Better operational reliability | Evaluate service contracts |

| Regular Maintenance | Prolonged equipment life | Set maintenance schedules |

| Customer Support | Rapid issue resolution | Review response times |

Investing in a welding machine from a supplier with robust support services enhances your operational reliability and overall return on investment.

Frequently Asked Questions

What Is the Average Lifespan of a Resistance Seam Welding Machine?

A resistance seam welding machine typically lasts between 10 to 15 years with proper maintenance. Regular inspections, timely repairs, and adherence to operational guidelines can greatly enhance its longevity and efficiency in production environments.

Can I Finance the Purchase of a Seam Welding Machine?

Yes, you can finance the purchase of a seam welding machine. Many suppliers offer financing options, allowing you to pay over time. Be sure to compare interest rates and terms to find the best deal.

What Are Common Maintenance Requirements for Seam Welders?

Think of your seam welder as a finely-tuned instrument. Regularly check and clean the electrodes, inspect electrical connections, lubricate moving parts, and calibrate settings to guarantee peak performance and longevity. Consistent maintenance prevents costly breakdowns.

Are There Warranty Options Available for Seam Welding Machines?

Yes, many manufacturers offer warranty options for seam welding machines. These typically cover parts and labor for a specific period. Be sure to read the terms carefully to understand coverage limits and conditions.

How Do I Choose the Right Seam Welder for My Needs?

To choose the right seam welder, consider that 70% of manufacturers prioritize durability. Assess your materials, production volume, and desired weld quality. Research machine specifications, and consult experts to match your operational needs effectively.

Conclusion

To summarize, understanding the cost of resistance seam welding machines involves more than just the initial price tag. You’ll find that factors like specifications, customizations, and additional services can greatly impact your investment. Notably, many buyers overlook the long-term savings associated with remanufactured machines. By exploring these options and considering total ownership costs, you can uncover hidden opportunities for efficiency and value that might just reshape your welding operations. Don’t underestimate the importance of thorough research in this decision-making process.