You’ll typically pay $20 to $100 to cut and weld an exhaust, depending on shop rates, job complexity, and whether parts are needed. Independent shops usually charge less than national chains, and localized pipe or muffler repairs cost far less than full-system or manifold work. Labor often makes up 25–40% of the bill, so get a parts-versus-labor breakdown. If you want a clearer estimate, keep going for factors, DIY tips, and how to pick a good shop.

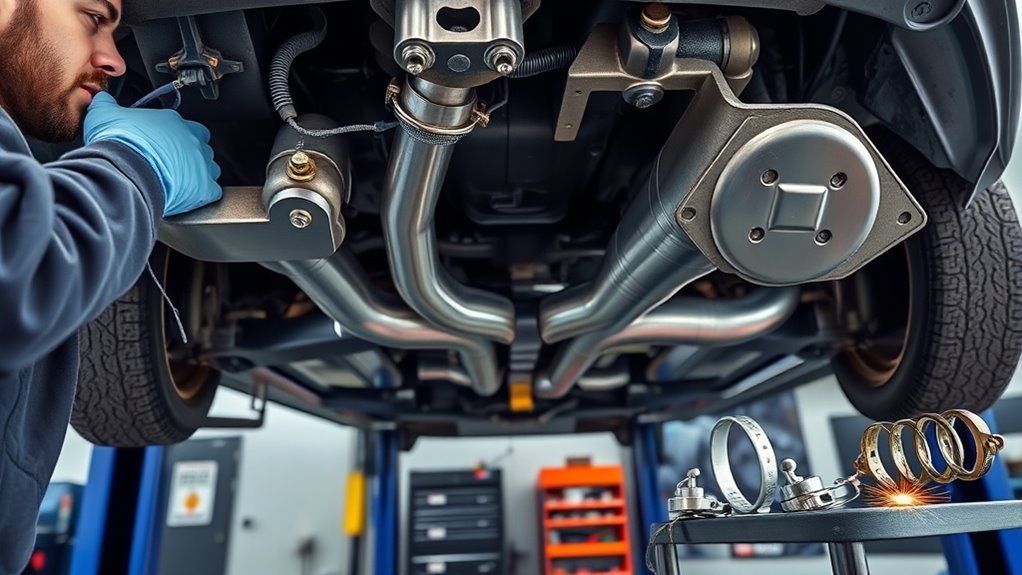

What the Exhaust System Does

Think of the exhaust system as your engine’s waste pipeline: it channels combustion gases safely out of the vehicle while cutting noise and emissions.

You rely on exhaust components—manifold, pipes, catalytic converter, muffler, tailpipe—to route exhaust, attenuate sound, and enable emissions reduction. The catalytic converter chemically converts CO, HC, and NOx into less harmful gases before they exit the tailpipe.

Mufflers and resonators use chambers and baffles to reduce acoustic energy. The manifold and piping maintain flow and backpressure for engine efficiency; damaged or corroded sections disrupt performance and raise emissions.

Regular inspections catch rust, leaks, or failed converters early, letting you repair or replace specific components rather than the entire system, preserving performance and regulatory compliance.

Typical Cost Range for Cutting and Welding an Exhaust

You can expect cutting and welding an exhaust to run roughly $20–$100 depending on shop rates and job complexity.

Prices trend lower at small independent shops and higher at national chains, with common welding quotes around $40–$75 and regional averages pushing some jobs to about $100.

Remember labor often makes up 25–40% of the total, so ask for a parts vs. labor breakdown when comparing estimates.

Typical Price Range

Typical exhaust cutting and welding jobs usually cost between $20 and $100, with independent local shops often charging less than national chains like Midas or Meineke.

You’ll see quotes like $20 for a simple 3-inch weld and $40–$75 for more involved work; complexity and technician experience drive the upper end.

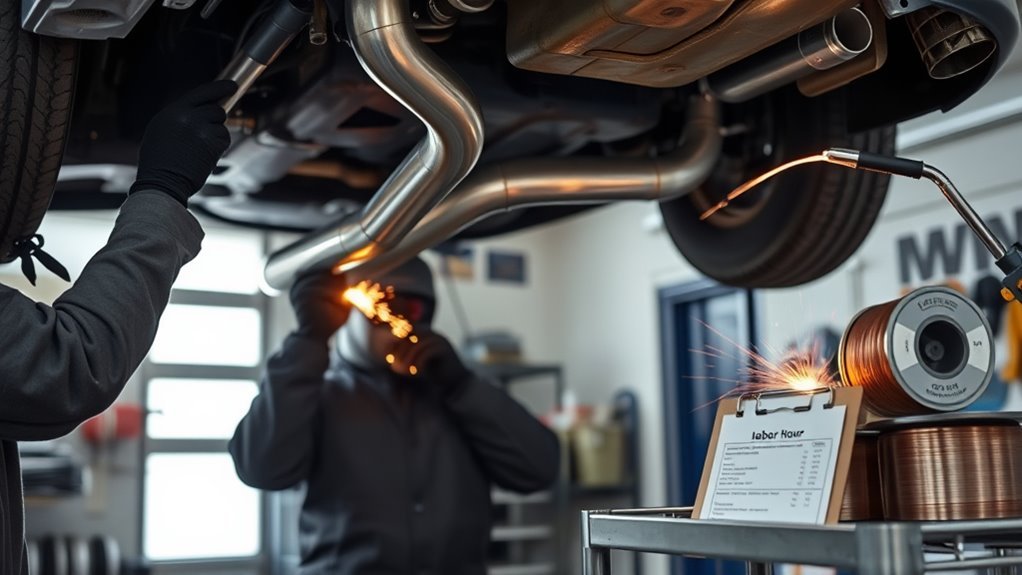

Apply practical welding techniques—MIG or TIG—based on material and access, and expect time-and-skill to influence labor charges.

Use transparent pricing strategies: ask for hourly rates, flat fees per weld, and parts/labor breakdowns.

Don’t assume chains are cheaper; independents often undercut them.

Factor in service quality and local economic conditions when you compare estimates so you can pick the most cost-effective, technically sound option.

Regional Price Differences

After comparing quotes and techniques, it helps to look at how location shifts price: exhaust cutting and welding commonly runs from about $20 to $100, but local markets push that range lower or higher.

You’ll use cost comparison and regional trends to set expectations: an independent shop in a lower-cost town may charge around $30, while a DC-area shop charging $100 reflects higher labor rates and overhead.

National chains often sit above independents; smaller shops usually give better rates for straightforward cuts or basic MIG welds.

If the job needs TIG or more complex pipe work, expect the high end regardless of region.

Always get local quotes, note shop reputation, and factor regional economic conditions into your decision.

Labor Versus Parts

When weighing labor versus parts for an exhaust cut-and-weld, focus first on what the shop will actually charge for hands-on time versus replacement components and consumables.

You’ll typically see total jobs from $20 to $100; that spread reflects labor costs, parts pricing, and technique. Expect hourly rates to range widely — $30 to $100+/hour — so a $40–$75 weld quote can be just labor.

Independent shops usually undercut national chains because of lower overhead, affecting your effective labor cost.

Parts pricing (clamps, pipes, flanges, gaskets) adds modestly but can spike if you need OEM items.

TIG or specialist welding raises both labor and time, so get line-item estimates separating labor costs and parts pricing before authorizing work.

Exhaust Pipe Repair Vs Full Replacement

If the damage to your exhaust is localized, repairing the pipe by cutting and welding will usually cost you between $20 and $100, making it far cheaper than a full system replacement that can run $500–$1,500 (with labor typically 25–40% of that total).

You’ll save immediately with targeted welding, and quality workmanship reduces recurrence, fitting practical cost saving strategies and exhaust longevity tips into routine maintenance.

Choose repair when corrosion or holes are limited to a section; replace when multiple components fail or the system’s age compromises future integrity.

Assess complexity, access, and part availability before deciding.

- Inspect extent of corrosion vs isolated hole.

- Estimate labor access time.

- Verify replacement part cost.

- Prioritize weld quality for longevity.

Manifold and Muffler Repair Costs Compared

When a manifold cracks you’ll weigh welding and patching (typically $500–$1,000) against full replacement ($900–$2,500) based on crack size and flange integrity.

For mufflers, you’ll compare a targeted repair or weld (often $20–$100 for labor) with swapping to an aftermarket ($50–$400) or OEM unit ($300–$1,000+), factoring labor ($75–$200).

Use component condition, parts lead time, and projected rust progression to pick the cost-effective option.

Manifold Crack Vs Replacement

Because a cracked exhaust manifold can often be welded for several hundred dollars, you’ll want to weigh that immediate savings against the longer-term risks and total costs of replacement.

You’ll compare repair longevity and manifold durability: welding typically costs $500–$1,000 and can restore function quickly, but heat cycles and poor penetration reduce repair longevity. Replacement runs $900–$2,500 and restores factory tolerances and durability.

- Inspect crack location and accessibility — affects welding success and labor.

- Evaluate gasket condition and associated labor ($250–$600) for resealing.

- Estimate shop welding rates ($20–$100) versus full replacement labor and parts.

- Factor vehicle-specific costs and workmanship quality into lifecycle cost.

Decide based on projected service life and risk of repeat failure.

Muffler Repair Vs Swap

After weighing manifold welding versus replacement, you’ll next compare muffler repair and full replacement to see where you can save money without sacrificing performance.

You’ll find muffler repairs usually cost $50–$400 for aftermarket units, while OEM mufflers run $300–$1,000+. Labor adds $75–$200, though you can DIY if you’ve got basic skills.

Consider muffler types — straight-through, chambered, turbo — to match backpressure and noise targets. Repair benefits include lower cost, faster turnaround, and targeted fixes for holes or seams; exhaust welds often run $20–$100 depending on complexity.

Because manifold jobs generally hit $900–$2,500, prioritizing muffler repair or selective swap preserves performance at a fraction of manifold replacement expense.

Factors That Influence Exhaust Welding Prices

Although labor and parts each play a role, the final price you’ll pay for cutting and welding an exhaust is driven by shop type, geographic labor rates, and job complexity.

You’ll pay less at local independent shops than national chains; welding techniques and exhaust materials also change time and consumable costs.

Geographic labor rates can swing by region, so a $30 labor market will be cheaper than higher-cost cities.

Complexity — access, corrosion, and custom bends — increases hours and precision work.

Building rapport can yield better quotes or minor discounts.

- Shop type: independent vs. chain affects markup and overhead.

- Labor rates: regional hourly differences determine baseline cost.

- Job complexity: rust, tight spaces, and custom work add time.

- Materials & techniques: stainless vs. aluminized and TIG vs. MIG.

DIY Welding: Tools, Safety, and When to Hire a Pro

Now that you know how shop type, labor rates, and job complexity affect shop prices, you might consider doing smaller exhaust repairs yourself to save money.

You’ll need a MIG welder, appropriate safety gear (face shield, welding shirt, gloves), and cleaning tools like a wire wheel to prep surfaces. Disconnect the negative battery cable before you start to avoid electrical damage.

Use proper welding techniques: tack welds to hold alignment, then adjust wire speed and arc volts for penetration without burn-through.

Evaluate the job complexity and your experience—simple patch panels or joint reworks are DIY candidates; rusted flanges, structural mounts, or unknown metallurgies mean hire a pro.

Shops charge roughly $20–$100 depending on scope.

How to Find the Best Local Shop and Get a Fair Price

Where should you take your exhaust to get good work at a fair price? Use local recommendations first: ask friends and community forums for smaller, independent shops with proven service quality rather than national chains.

Check online reviews and testimonials to verify reliability and past exhaust work.

Check online reviews and testimonials to confirm a shop’s reliability and past exhaust work quality.

- Compare quoted labor rates in your region — expect wide variance (≈$30–$100 for a basic weld).

- Confirm shop experience with exhaust-specific cutting and welding; ask for examples or photos.

- Inspect credentials, weld quality, and warranty terms before approving work.

- Build rapport with a trusted mechanic to negotiate better pricing and faster service.

You’ll avoid repeat repairs by prioritizing targeted experience and verifiable service quality when selecting a local shop.

Frequently Asked Questions

Can Welding Void My Vehicle’s Warranty?

Yes — you can void warranty coverage for related components if exhaust modifications cause damage. You should document professional work, use OEM-equivalent parts, and check manufacturer policy; unrelated systems should remain covered unless causation is proven.

Will Welding Affect Emissions or Make My Car Fail Inspection?

“A stitch in time saves nine”: you’ll usually avoid failing inspection if welding preserves exhaust emissions controls and meets inspection criteria; welds mustn’t bypass catalytic converters, oxygen sensors, or add leaks that alter emissions readings.

Can I Use Stainless Steel Patches Instead of Welding?

Yes — you can use stainless steel patches instead of welding; they offer corrosion resistance and durability. Use proper patching techniques: clean/degrease, clamp securely, apply high-temp sealant, and braze or use rivets for mechanical strength.

How Long Does a Welded Exhaust Repair Typically Last?

Like a sturdy bridge, a proper welded exhaust typically lasts 3–7 years depending on materials and conditions; welded exhaust durability improves with regular inspection, rust prevention, and repair maintenance tips like sealing joints and replacing corroded sections promptly.

Is Mobile Welding More Expensive Than Shop Welding?

Yes — mobile welding’s usually pricier per hour, but you’ll gain mobile welding benefits like convenience, faster turnaround, and on-site diagnostics. For a clear cost comparison, weigh travel premiums against shop hourly rates and equipment access.

Conclusion

You’ve seen what the exhaust does and what cutting, welding, and replacement typically cost, so choose confidently. Compare quotes, check certifications, and consider cost versus corroded components before committing. Do-it-yourself only if you’ve got the right tools, technique, and toughness; otherwise hire a pro. Prioritize proven pros with transparent pricing and warranties to prevent repeat repairs, preserve performance, and protect emissions — practical, precise, and prepared choices pay off.