You’ll typically pay a welder $50–$125 per hour (labor is about 60–70% of total cost) plus materials and consumables that add roughly 10%. Rates vary by process: stick $50–75, MIG $65–90, TIG $75–125, FCAW $55–90. Material affects price too: mild steel is cheapest, stainless and aluminum are 1.5–2× higher per inch. Small jobs may have 1–2 hour minimums; complex or certified work costs more — keep reading for a full breakdown.

Average Welding Rates and What They Cover

Anyone hiring a welder should expect typical hourly rates between $50 and $125, which bundle the welder’s wage, equipment use, overhead, and basic consumables.

You’ll find labor makes up roughly 60–70% of total project expense, so hourly shop rates reflect skill and indirect costs.

Expect material charges separately: mild steel ~ $0.50–$2.00 per inch, stainless and aluminum $1.00–$4.00 per inch depending on complexity.

Welders may apply a minimum fee equal to 1–2 labor hours to cover travel and setup, affecting small jobs.

In your project planning, allocate contingency for complexity and consumables.

Maintain welding safety by budgeting for PPE, ventilation, and pre-job inspection to avoid rework and hidden cost escalation.

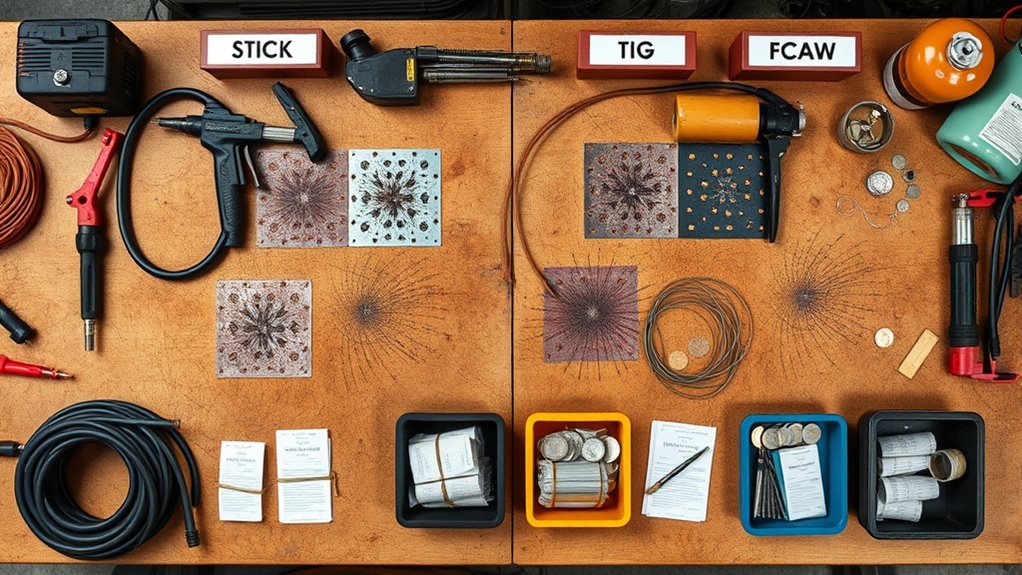

Costs by Welding Method (Stick, MIG, TIG, FCAW)

Compare hourly rates first: stick runs about $50–$75, MIG $65–$90, TIG $75–$125, and FCAW $55–$90, so you can see immediate cost differentials.

Then factor material-specific costs—thin stainless or aluminum with TIG raises labor and filler cost, while carbon steel with FCAW or MIG reduces per-inch price.

Finally assess complexity and prep time, since joint fit-up, cleaning, and positional work can push a lower hourly rate into a higher total project cost.

Hourly Rate Comparison

When budgeting a welding job, you’ll need to account for method-specific hourly rates—stick runs about $50–$75/hr, MIG $65–$90/hr, TIG $75–$125/hr, and FCAW $55–$90/hr—because labor typically makes up 60–70% of total costs and directly drives overall project expense.

You should select welding techniques that match joint design, tolerance, and throughput requirements: stick for simple field repairs, MIG for faster production work, TIG for precision or aesthetic-critical joints, FCAW for heavy fabrication.

Compare hourly rates against expected weld time, accessibility, and operator skill to calculate realistic labor totals. Track effective deposition rates and rework likelihood per method; small time differences scale into substantial cost variance.

Use these rate bands in project budgeting to prioritize method efficiency and quality trade-offs.

Material-Specific Costs

The costs you’ll see for each welding method combine operator hours and consumables, so pick the process that matches material, joint size, and finish requirements. You’ll weigh welding techniques against material properties: Stick ($50–$75/hr) for mild steel, MIG ($65–$90/hr) for speed with mild steel or aluminum, TIG ($75–$125/hr) for precision on stainless or aluminum, and FCAW ($55–$90/hr) for outdoor or thick sections. Material charge per inch further shifts cost: mild steel $0.50–$2.00, stainless $1.00–$3.50, aluminum $1.25–$4.00. Use the table below to feel the trade-offs quickly.

| Method | Emotional weight |

|---|---|

| TIG | precise, costly |

| MIG | efficient, versatile |

| FCAW/Stick | rugged, economical |

Complexity & Prep Time

Because complexity and prep time directly drive labor hours, you’ll see considerable cost variation between Stick, MIG, TIG, and FCAW jobs.

You must assess project accessibility and design intricacy before quoting: tight joints, awkward orientations, or confined spaces increase setup, fixturing, and welding time.

Stick runs $50–$75/hr and suits field repairs with minimal prep; MIG at $65–$90/hr speeds production but needs clean joints and proper fit-up.

TIG, $75–$125/hr, demands the most prep and skill for thin or exotic metals, raising labor considerably.

FCAW at $55–$90/hr handles heavy sections with less edge prep but still suffers when access is limited.

Material type and required bead length (mild steel vs. aluminum) add per-inch costs and premium labor for intricate metallurgy.

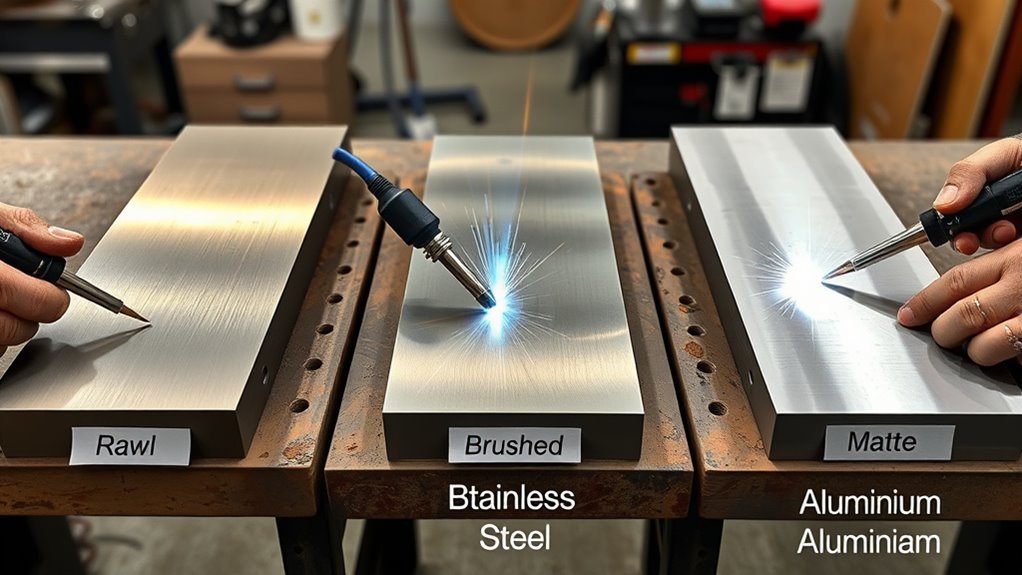

Price Differences by Metal Type (Steel, Stainless, Aluminum)

You’ll see clear cost tiers by metal type: mild steel typically runs $0.50–$2.00 per inch, stainless steel about $1.00–$3.50 per inch, and aluminum roughly $1.25–$4.00 per inch.

Expect higher labor and technique premiums for stainless and aluminum, since they require specialized procedures and account for roughly 60–70% of total project cost.

Also factor in material-price volatility—aluminum and stainless prices can spike during market swings, changing project estimates.

Mild Steel Costs

1 key cost driver in welding projects is metal selection, and mild steel usually gives you the lowest per-inch welding rate—about $0.50 to $2.00—because it’s widely available, easy to weld, and requires less-prepared joint fit-up than stainless or aluminum.

You’ll find mild steel advantages in faster travel speeds, lower filler consumption, and less stringent pre/post-heat controls, all reducing labor and consumable costs.

For common mild steel applications — structural frames, brackets, fixtures, and repair work — expect predictable weld quality with MIG or stick processes.

Material thickness and joint complexity still affect labor time and heat input, so quote accordingly.

Compared to stainless and aluminum, mild steel minimizes total project cost, especially for large linear weld lengths where per-inch savings compound.

Stainless Steel Pricing

When comparing metal types for welding costs, stainless steel typically runs higher than mild steel—about $1.00 to $3.50 per inch versus $0.50 to $2.00—because it demands tighter joint preparation, slower travel speeds, and often specialized filler metals and shielding to control contamination and heat tint.

You’ll pay more as complexity and thickness increase, since thicker sections require preheat, interpass temperature control, and more precise welding techniques.

Stainless’s corrosion resistance and strength justify costs in critical stainless applications like food, chemical, and medical equipment.

Expect material price fluctuations to affect quotes; stainless market swings raise base costs and consumable pricing.

Budget for skilled operators and appropriate equipment when specifying stainless work to avoid rework and guarantee consistent metallurgical properties.

Aluminum Welding Rates

Aluminum welding typically runs $1.25–$4.00 per inch of weld, making it generally more expensive than mild steel ($0.50–$2.00/in) and often costlier than stainless ($1.00–$3.50/in) because aluminum’s thermal conductivity, oxide layer, and low melting point demand specialized techniques, filler metals, and equipment.

You’ll pay more because aluminum welding techniques require controlled heat input, AC TIG or pulse MIG setups, and skilled operators. Material thickness and joint complexity raise labor time and prep costs. TIG rates ($75–$125/hr) often drive final price for precision aluminum welding applications.

- Thin-gauge parts need strict heat control and oxide removal.

- Thicker sections demand preheat and specific filler alloys.

- Cleanliness and fit-up increase labor time.

- Specialized equipment raises hourly shop rates.

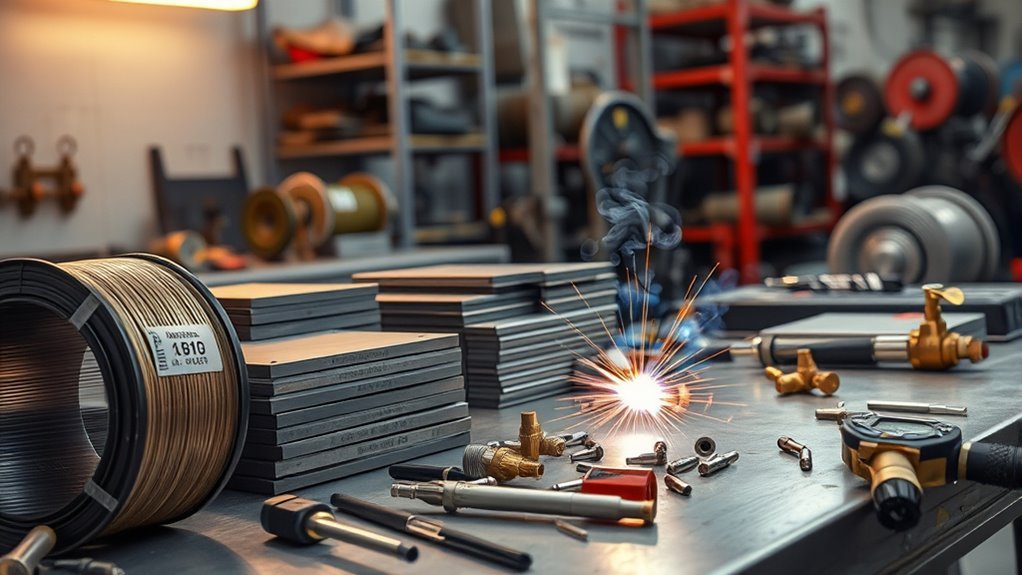

Typical Material and Consumable Expenses

Expect consumables to add roughly 10% to your total welding project cost, driven by items like filler metals, tungsten electrodes, shielding gas, and abrasives. You’ll budget welding supplies into a clear cost breakdown: wire (~$40/30 lb), flux or gas ($120–$150 per 1.5–2 weeks), sanding paper (~$64/week), plus electrodes and filler metals whose prices vary by metal type. Mild steel keeps consumable costs lowest; aluminum or stainless multiply them 1.5–2×. Track weekly and project totals to avoid surprises, and choose processes that minimize gas or specialty filler consumption when possible.

| Item | Typical Price | Frequency |

|---|---|---|

| Wire (30 lb) | $40 | per roll |

| Flux/Gas | $120–$150 | 1.5–2 weeks |

| Sanding paper | $64 | weekly |

How Project Complexity Impacts Price

Because complexity multiplies both labor and materials, you’ll pay noticeably more for intricate welding than for straightforward seams.

Because complexity multiplies labor and materials, intricate welding costs significantly more than simple seams.

You’ll need advanced welding techniques and more intensive project planning when thickness, alloys, and access complicate execution. Expect higher hourly rates for experienced welders and longer shop time for prep, fit-up, and multi-pass welds.

Consumables also rise: specialty filler metals, fluxes, and shielding gases add cost.

- Thick or exotic metals demand preheat, interpass control, and specific welding techniques.

- Tight or awkward access increases labor hours and fixturing needs.

- Higher-skilled operators command premium rates; certification level matters.

- More consumables and inspection steps (NDT, radiography) elevate final pricing.

Estimating Total Project Costs and Using a Calculator

Now that you’ve considered how complexity drives labor, materials, and inspection needs, it’s time to quantify those factors so you can set a realistic budget.

You’ll build a welding budget by calculating labor (typically $50–$125/hr), which usually represents 60–70% of total costs. Add material premiums: mild steel baseline, aluminum or stainless at 1.5–2×. Include filler metals and consumables (~10% of total).

Factor complexity adjustments for size, shape, and accessibility into hourly estimates or added setup time.

Use a welding cost calculator to input welding method, material type, and estimated hours; it returns a precise cost breakdown and highlights dominant cost drivers.

Verify calculator outputs against local labor rates and update for inspections or specialty procedures.

Ways to Save on Welding Costs

If you plan and set up carefully, you can cut welding costs considerably by reducing billable shop time, material waste, and unnecessary travel. You’ll lower expenses by doing prep work, specifying simpler joints, choosing affordable metals, and scheduling to capture welding discounts and bulk pricing.

Use clear project budgeting to track savings and avoid scope creep.

- Clean and organize materials before the welder arrives to minimize labor hours.

- Simplify design and reduce complex welds to shorten skilled labor time.

- Select mild steel when appropriate to decrease material costs versus aluminum or stainless.

- Hire mobile welders to reduce transport fees and shop overhead.

Implement these tactics in your project budgeting to realize measurable cost reductions.

Questions to Ask When Getting Welding Quotes

After you’ve trimmed design complexity and organized materials to lower shop hours, focus on the questions that will make quotes comparable and reliable. Ask hourly rates ($50–$125) and minimum fees, request itemized estimates covering labor, materials, and complexity surcharges, and confirm experience with stainless, aluminum, or other specific metals. Verify certifications, insurance, and welding safety protocols. Ask for a projected project timeline and milestones, plus contingencies for rework or delays. Collect multiple quotes to benchmark pricing and services. Use the table below to standardize comparisons.

| Item | Question | Expected Answer |

|---|---|---|

| Rate | Hourly/minimum fee | $50–$125; specify minimum |

| Scope | Itemized costs | Labor, materials, extras |

| Credentials | Certs/insurance/timeline | Proof, safety plan, ETA |

Frequently Asked Questions

Do Welders Need Certification Beyond Basic Training for My Project?

Yes — you’ll likely need certification beyond basic training. Assess certification types (AWS, ASME, CWB), verify project codes, and require specific training programs or endorsements for materials, positions, and procedures to guarantee qualified, code-compliant welders.

How Long Will My Welded Repair or Build Take to Complete?

You’ll get it done “in no time” — realistically, repair timelines vary: simple fixes take hours, moderate projects a day or two, complex fabrications several days to weeks; project complexity, access, and inspections determine actual duration.

Are There Warranty or Guarantee Terms on Welding Workmanship?

Yes — you’ll get warranty terms covering workmanship; they’ll specify duration, coverage limits, and remediation steps. Expect welding quality assurance protocols and craftsmanship evaluation criteria, including inspection methods, acceptance standards, and corrective action procedures.

Can Welding Work Be Scheduled for Evenings or Weekends?

Yes — you can schedule welding work for evenings or weekends. We offer welding availability with scheduling flexibility; you’ll select specific times, confirm technician qualifications, and receive precise start windows plus contingency plans for equipment or permit-related delays.

Do Environmental Regulations Affect Where Welding Can Be Performed?

Yes — environmental regulations restrict welding locations: you’ll assess environmental impact, control emissions, manage waste, and guarantee regulatory compliance for ventilation, permits, and containment. Noncompliance can halt work, trigger fines, or require relocation.

Conclusion

You want predictability, but welding costs fluctuate — hourly rates, metal type, and complexity pull price in opposite directions. You’ll pay less per inch on simple steel MIG work, yet a tiny TIG stainless repair can cost more because of skill and prep. Balance labor, consumables, and travel when comparing quotes, and demand detailed line items. With clear specs and smart choices, you’ll turn uncertainty into a reliable budget rather than a surprise bill.