Replacing a torque converter can be essential for your vehicle’s health. But how much does it cost?

The expense of replacing a torque converter can vary greatly. Factors include the type of vehicle, labor costs, and parts prices. Knowing the cost helps you budget and avoid surprises. In this blog, we’ll explore the factors that influence the price.

You’ll gain insight into what you might expect to pay. This knowledge is crucial for making informed decisions about your car’s maintenance. Let’s dive in and break down the costs involved in torque converter replacement and Find the answer for the question “How Much Does It Cost to Replace a Torque Converter?”

As an Amazon Associate, I earn from qualifying purchases.

As automotive expert John Smith from AutoRepairGuide.com explains, “Replacing a torque converter is a big job, but it’s also a crucial one. Getting it fixed as soon as you notice issues can save you from a more expensive transmission rebuild later.”

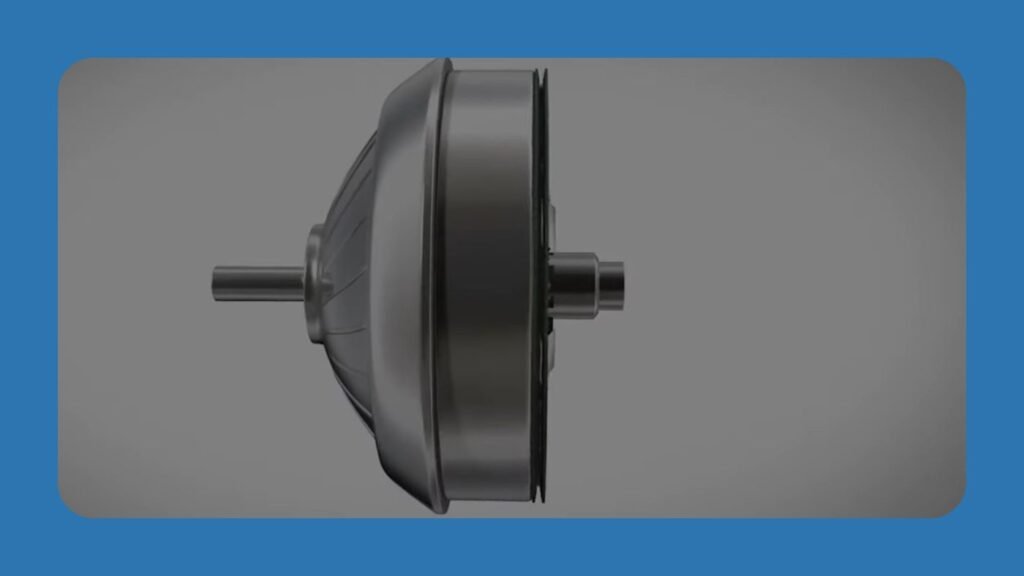

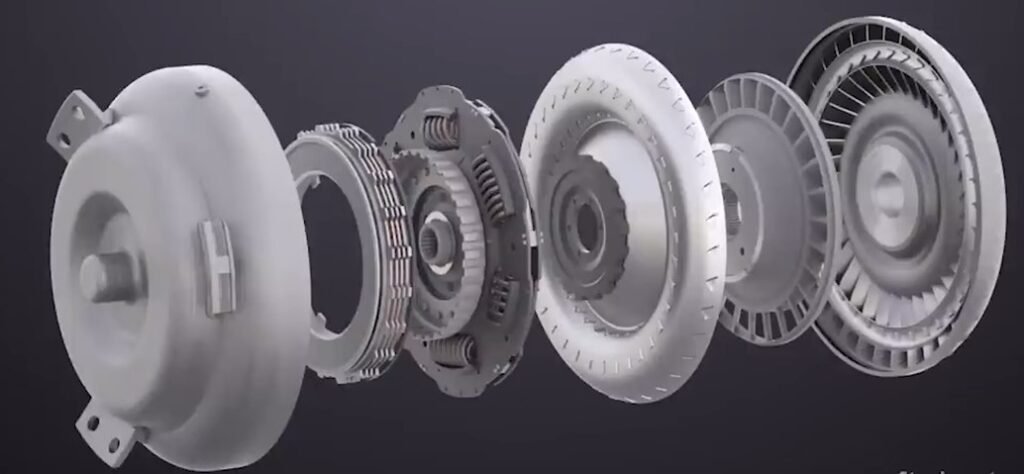

Introduction To Torque Converters

Torque converters play a critical role in automatic transmissions. They connect the engine to the transmission and allow the vehicle to change gears smoothly. Understanding their function is key to grasping their importance in vehicle performance.

Role In-Vehicle Performance

Torque converters enhance vehicle performance. They transfer power from the engine to the transmission. This allows the vehicle to start and stop smoothly. They also multiply engine torque, providing better acceleration.

Without a functioning torque converter, the vehicle may struggle. It might have difficulty shifting gears or accelerating. This component ensures a smooth and efficient driving experience.

Common Issues And Failures

Torque converters can develop several issues. A common problem is slipping. This occurs when the converter fails to transfer power effectively. The vehicle may struggle to accelerate or feel sluggish.

Another issue is overheating. Overheating can cause damage to the internal components. It can lead to a complete failure of the torque converter.

Contamination is also a concern. Dirt and debris can enter the torque converter. This can cause it to malfunction or fail. Regular maintenance helps prevent these issues.

Signs Of A Failing Torque Converter

Recognizing the signs of a failing torque converter can save you from bigger problems. A malfunctioning torque converter can affect your vehicle’s performance. Below are the common signs you might notice if your torque converter is failing.

Transmission Slippage

Transmission slippage is a key indicator of a failing torque converter. You may notice your car struggling to change gears. The vehicle might also slip into neutral without your input. This can happen at random times, making driving unsafe.

| Indicator | Description |

|---|---|

| Gear Changes | Difficulty in changing gears or delayed shifts |

| Neutral Slipping | Car slips into neutral without input |

Overheating And Noise

Another sign is overheating and noise. A failing torque converter can cause your transmission to overheat. This may trigger a warning light on your dashboard. You may also hear strange noises. These noises can include whirring, clicking, or grinding sounds.

- Whirring sounds

- Clicking noises

- Grinding sounds

If you notice these signs, it’s best to get your car checked. Early diagnosis can save you from expensive repairs.

BlueDriver Bluetooth Pro OBD2 Scan Tool

A pro-grade code reader that pairs with your phone to pull transmission-related trouble codes and live data, helping you confirm symptoms like slipping or overheating before you book repairs.

Sarah Lee, a seasoned mechanic, also adds, “Not all torque converters are made equal. Choosing the right one—whether OEM or aftermarket—depends on your car and your budget. Make sure you’re getting good value for your money.”

Factors Influencing Replacement Cost

When replacing a torque converter, several factors affect the cost. Each factor can influence the final price significantly. Below, we’ll explore the main factors that impact the replacement cost.

Type Of Vehicle

The type of vehicle plays a crucial role in determining the cost of replacing a torque converter. Different vehicles have varying designs, parts, and complexity. Here are some examples:

- Compact cars usually cost less to repair compared to larger vehicles.

- Luxury cars often have higher replacement costs due to specialized parts.

- Trucks and SUVs may require more labor and expensive parts.

Additionally, older vehicles might have cheaper parts, but finding them can be difficult. Newer models often have more expensive, advanced parts.

Labor Costs

Labor costs are another significant factor in the overall expense. Labor costs vary based on location, the complexity of the job, and the mechanic’s expertise. Here’s a breakdown:

| Location | Average Labor Cost |

|---|---|

| Urban areas | $100 – $150 per hour |

| Rural areas | $70 – $100 per hour |

Actual market rates vary by state and shop; many U.S. markets report average posted rates in the ~$100–$150+ per-hour range in 2025.

Average Cost Of Replacement

The cost to replace a torque converter varies. Several factors influence this cost. Understanding these factors can help you budget for the repair. Estimates below reflect typical U.S. pricing as of August 2025.

Parts And Labor Breakdown

The cost of a torque converter itself ranges between $150 and $500. High-performance or specialty converters can be more expensive. Labor costs vary based on the mechanic’s hourly rate. On average, expect to pay about $400 to $900+ for labor, since book time is often 5–10 hours. Replacing a torque converter requires skill and time, adding to the labor costs.

Regional Variations

Costs can differ based on location. Urban areas tend to have higher labor rates. Rural areas might offer lower prices. Local demand and availability of parts also impact the cost. Research your area to find the best prices. Comparing quotes from different mechanics can save money.

Diy Vs. Professional Replacement

Replacing a torque converter can cost between $600 and $1,400 if done professionally (U.S.). DIY replacement may cost less but requires significant skill. Consider both the expense and expertise needed before deciding.

Replacing a torque converter can be a challenging task. Deciding between DIY and professional replacement requires careful consideration. Each option has its own set of advantages and disadvantages.

Pros And Cons

DIY Replacement

- Cost Savings: You save on labor costs.

- Learning Experience: Gain valuable hands-on experience.

- Flexibility: Work on your own schedule.

Cons:

- Time-Consuming: Can take longer without professional tools.

- Risk of Errors: Mistakes can be costly to fix.

- Physical Strain: Requires significant physical effort.

Professional Replacement

- Expertise: Mechanics have specialized knowledge.

- Warranty: Professional work often comes with a warranty.

- Time-Efficient: Professionals can complete the task faster.

Cons:

- Higher Cost: Labor costs can be expensive.

- Less Control: Rely on the mechanic’s schedule and availability.

Required Tools And Skills

DIY Replacement

To replace a torque converter yourself, you need specific tools and skills. Here is a basic list:

- Socket Set: Various sizes for different bolts.

- Torque Wrench: Ensure bolts are tightened properly.

- Transmission Jack: Safely lift and lower the transmission.

- Basic Mechanical Knowledge: Understanding of car components.

- Repair Manual: Step-by-step instructions specific to your vehicle.

Skills Needed:

- Basic Mechanical Skills: Understand how car parts work.

- Attention to Detail: Ensure everything is done correctly.

- Patience: The process can be slow and detailed.

Professional Replacement

Professionals have access to advanced tools and specialized skills. They can handle complex repairs efficiently. This option is ideal if you lack the necessary tools or skills.

Warranty And Insurance Considerations

When replacing a torque converter, understanding warranty and insurance options is crucial. These can help manage repair costs and provide peace of mind.

Coverage Options

Many warranties cover torque converter replacement. Check if your vehicle’s warranty includes powertrain components. Manufacturers typically list the torque converter under transmission coverage in the powertrain booklet; always confirm details in your model-year guide.

Extended warranties often cover torque converters. They can be purchased from the manufacturer or third-party providers.

Insurance policies might offer coverage too. Check with your provider about mechanical breakdown insurance. Standard auto insurance generally does not cover mechanical failure; MBI (if available in your state) is an optional add-on that may cover major components like the transmission/torque converter.

| Warranty Type | Coverage |

|---|---|

| Manufacturer Warranty | Often includes powertrain components |

| Extended Warranty | Can include torque converters |

| Mechanical Breakdown Insurance | May cover torque converter replacement |

Claim Process

Filing a claim for torque converter replacement involves several steps. First, gather all necessary documents. This includes receipts and service records.

Next, contact your warranty or insurance provider. Explain the issue clearly. Provide all required documentation.

An adjuster may inspect your vehicle. They will determine if the replacement is covered. Once approved, the provider will cover the costs as per the policy terms.

- Gather necessary documents

- Contact your provider

- Explain the issue

- Provide required documentation

- Wait for approval

Understanding your warranty and insurance coverage can save you money. It ensures that your torque converter replacement is hassle-free.

Mike Johnson, a car repair consultant, says, “Torque converter issues often go unnoticed until they become severe. Paying attention to your car’s behavior early on can help prevent costly repairs down the road.”

Cost-saving Tips

Replacing a torque converter can be costly. But there are ways to save money. Here are some cost-saving tips to help you.

Sourcing Affordable Parts

First, find affordable parts. Check local auto shops for deals. Compare prices online too. Some websites offer discounts on auto parts. Look for refurbished parts. They are cheaper and work well. Always check the warranty. It protects your purchase.

LUBEGARD 19610 Instant Shudder Fixx (2 oz)

A compact friction modifier used in service bays for addressing torque-converter shudder. Useful as a diagnostic aid or interim step—always verify fluid specs and follow your vehicle’s service guidance.

Choosing The Right Mechanic

Next, choose the right mechanic. Not all mechanics charge the same. Ask friends for recommendations. Read online reviews. Find a mechanic with fair prices. Some shops offer free inspections. Use them to get a quote. Compare quotes from different mechanics. Pick one with good service and fair pricing. Remember, a good mechanic saves you money in the long run.

Preventive Maintenance

Preventive maintenance is key to avoiding costly torque converter replacements. Simple steps can help extend the life of your vehicle’s components. Focus on the transmission system. This ensures smooth operation and minimizes wear and tear.

Extending Torque Converter Life

Follow a regular maintenance schedule. Change the transmission fluid as recommended. Clean fluid helps the torque converter function efficiently. Check for leaks. Address them immediately. Leaks can cause significant damage. Use high-quality transmission fluid. This keeps the system in top shape.

Hayden 679 Rapid-Cool Add-On Transmission Cooler

An auxiliary plate-and-fin cooler designed to help keep ATF temperatures in check during towing, hills, or hot climates—supporting transmission and torque-converter longevity.

Regular Transmission Checks

Regularly inspect the transmission. Look for signs of trouble. Unusual noises or rough shifting can indicate issues. Address them early. This prevents more serious problems. A professional mechanic can perform thorough checks. They can spot and fix minor issues. This saves you money in the long run.

Frequently Asked Questions

What Is The Average Cost To Replace A Torque Converter?

The average cost to replace a torque converter ranges between $600 and $1,400 (parts and labor, U.S.). Prices vary based on vehicle make and model.

How Long Does It Take To Replace A Torque Converter?

It typically takes a mechanic about 5 to 10 hours to replace a torque converter. Time can vary by vehicle.

Can I Drive With A Bad Torque Converter?

Driving with a bad torque converter can cause further damage to your transmission. It’s best to replace it promptly.

What Are The Symptoms Of A Failing Torque Converter?

Symptoms include slipping gears, overheating, shuddering, and strange noises. If you notice these signs, consult a mechanic.

Conclusion

Replacing a torque converter can be expensive but necessary. Costs vary widely. Labor and parts influence the total price. Always get multiple quotes. This ensures a fair price. Regular maintenance can prevent sudden failures. Protect your vehicle and wallet. Research trusted mechanics.

Quality work matters. Consider the long-term benefits. A well-maintained car runs smoother. Save money on future repairs. Budget for unexpected expenses. This helps avoid stress. Keep your car in top shape. Enjoy a reliable ride.