You can cut distortion, rework and filler waste by controlling heat input, right‑sizing welds and sequencing symmetrically about the neutral axis. Use intermittent and backstep patterns, minimize passes with properly matched electrode size, and keep arc length and travel angle consistent to reduce shrinkage. Pre‑set strong jigs, clamp against shrink vectors, and consider water‑cooled fixtures or controlled peening for stress control. Follow documented WPS and qualified operators — more specific techniques and parameters follow below.

What Is Welding Distortion and Why It Happens

Because welding heats and then cools metal unevenly, distortion happens when expansion and contraction are restrained, causing the weldment to warp and lose dimensional integrity.

You’ll recognize welding distortion as dimensional change from thermal expansion/contraction of weld and base metal; the arc’s heat causes local expansion and, if restrained, contraction during cooling produces warpage.

Apply controlled welding techniques to manage heat input and sequence, reducing uneven thermal effects that generate residual stress.

Use intermittent welds and planned stitch patterns to cut heat transfer and weld metal usage—often up to 75% reduction—while maintaining strength.

Position welds near the neutral axis and plan sequencing to balance forces and minimize leverage for distortion.

Inspect dimensions against standards and adjust technique to meet tolerance requirements.

Right-Sizing Your Welds to Reduce Shrinkage

When you size welds to the joint’s load and geometry, you cut shrinkage forces and the risk of distortion without sacrificing strength.

You match weld size to required throat and tensile capacity to avoid overwelding and preserve material efficiency. For plates over 0.25 in, bevel edges to create joint access that reduces filler metal volume.

Use fewer, larger passes when appropriate to limit cumulative shrinkage from repeated thermal cycles. Inspect and document weld procedure specs to guarantee consistent application.

Use fewer, larger weld passes when suitable to reduce cumulative shrinkage; always document and verify procedure specifications for consistency.

- Match weld size to design throat and load case

- Bevel thick plates to lower filler volume and heat input

- Prefer controlled larger passes over many small passes

- Verify procedures and measure finished dimensions against prints

This approach improves integrity and minimizes distortion.

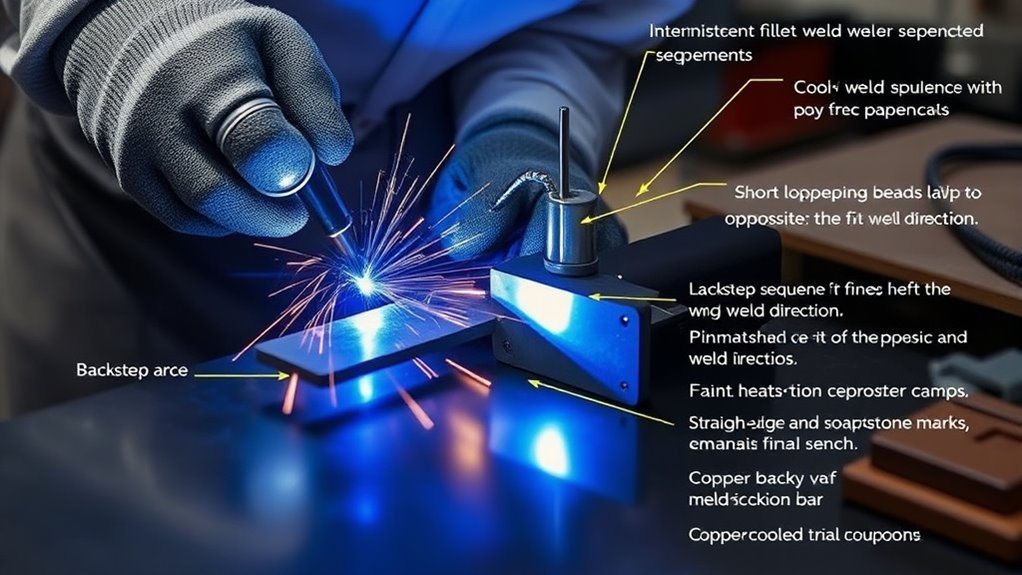

Intermittent and Backstep Welding Techniques

Although you’ll usually use continuous beads for full-strength joints, intermittent and backstep techniques let you cut heat input and weld metal by as much as 75% while preserving required strength and alignment.

Intermittent welding spaces welds to control shrinkage and metal usage, and backstep welding sequences beads in alternating directions so heat is distributed outward evenly, bringing plates back together and reducing distortion.

You’ll apply intermittent welding when continuous welds are unnecessary; specify weld length, pitch, and end conditions to meet code and structural requirements.

Use backstep welding to sequence short beads opposite the overall travel direction so heat flow counteracts distortion.

Both methods demand documented procedures, qualified operators, and inspection criteria to guarantee strength, alignment, and minimized warpage.

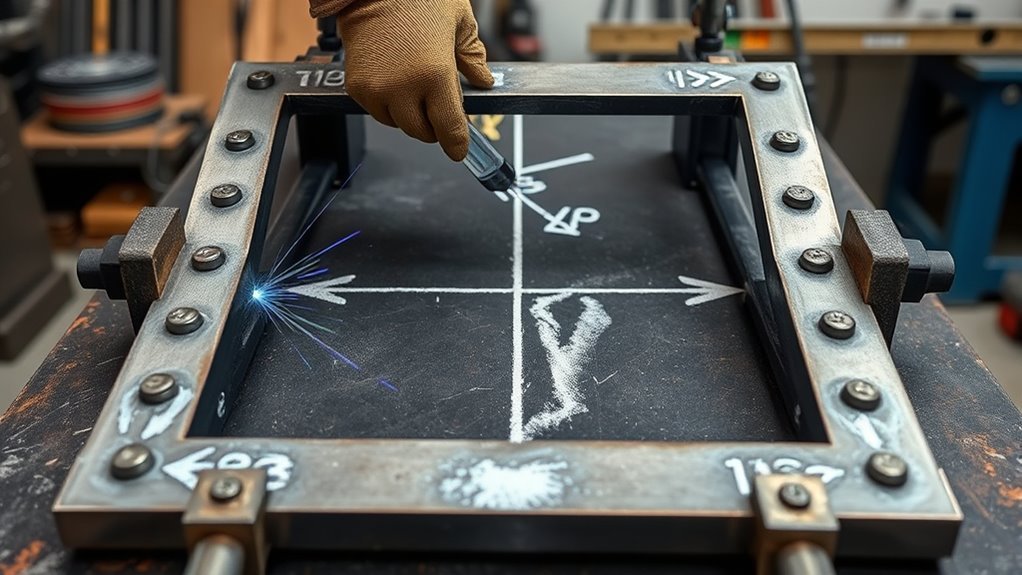

Planning Weld Sequence and Balancing Around the Neutral Axis

To control shrinkage and minimize distortion, plan your weld sequence so welds are placed and executed symmetrically around the neutral axis, alternating sides and locations to keep net restraint forces near zero.

Plan welds symmetrically around the neutral axis, alternating sides to balance restraint forces and minimize distortion.

You’ll sequence weld placement to let shrinkage occur locally, one region at a time, preventing cumulative distortion. Balance around the neutral axis to offset thermal forces and preserve alignment.

Use intermittent welds strategically to limit heat input and material use while maintaining equilibrium. Follow code-based tolerances and document sequence steps.

- Alternate welds left/right of the neutral axis to neutralize bending moments.

- Sequence from stiff, central members outward to control constraint.

- Insert short intermittent welds where full seams aren’t required.

- Verify alignment after each critical pass and adjust sequence as needed.

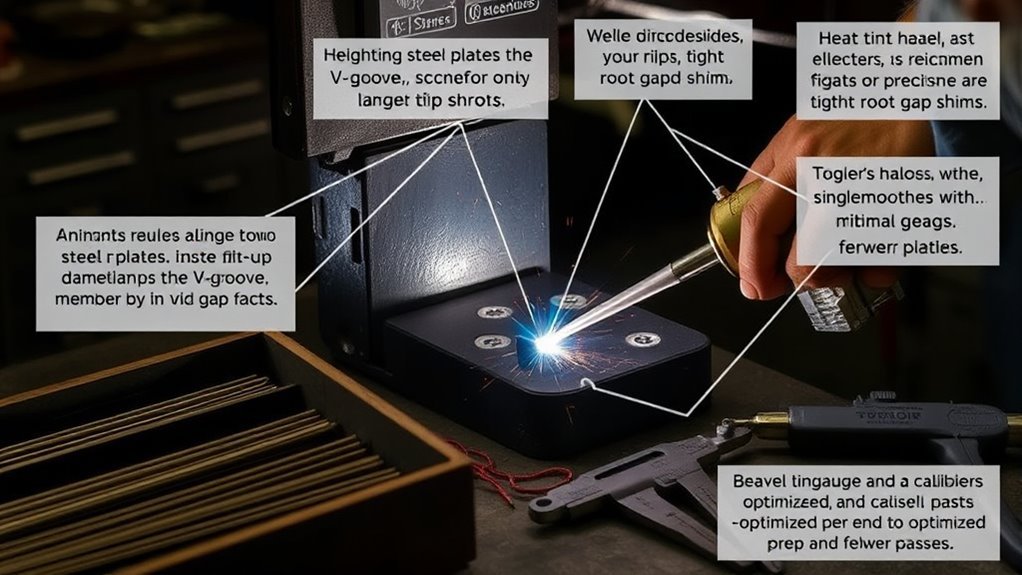

Minimizing Number of Weld Passes and Optimizing Electrode Size

You should plan for fewer, larger passes to limit cumulative shrinkage and simplify thermal control.

Match electrode diameter to joint geometry and material thickness so each pass achieves full penetration without over‑welding.

Where code and fit‑up allow, use single‑pass techniques with a larger electrode for sections over 0.25 in to maintain strength and reduce defect risk.

Fewer, Larger Passes

When you reduce the number of weld passes and choose larger electrodes, you cut cumulative shrinkage and lower distortion risk while maintaining required deposit properties; aim for no more than one pass per 1/4 inch of thickness and select an electrode that reliably deposits the needed bead geometry in that single pass.

You’ll optimize pass selection to balance heat input, deposition rate, and mechanical properties, preserving weld quality and lowering rework. Use procedure qualification to validate single-pass strength, heat-affected zone extent, and defect absence.

- Larger electrode reduces passes, shortens cycle time, and lowers total heat input.

- One pass per 1/4″ limits cumulative distortion and simplifies fixturing.

- Fewer passes improve bead appearance and reduce cold-lap risk.

- Verify parameters per code and record for traceability.

Match Electrode Diameter

Having reduced pass count with larger electrodes in the previous section, now match electrode diameter to material thickness so each bead achieves proper penetration and deposition in as few passes as practical.

You’ll apply the rule of thumb: roughly 1 amp per 0.001″ of electrode diameter to set welding current precisely during electrode selection. For materials over 1/4″ choose larger diameters (3/32″, 1/8″) to increase penetration, deposition rate, and reduce cold-lap risk.

Fewer passes lower cumulative shrinkage and distortion; you’ll document parameters to meet code and repeatability.

Verify material compatibility—coating, alloy, and joint geometry—before sizing electrodes. Optimize travel speed and angle to match diameter, then confirm fusion with inspection.

This disciplined approach saves time, consumables, and preserves weld integrity.

Single-Pass Techniques

Because single-pass techniques cut cumulative heat input and shrinkage, adopt them wherever joint design and material thickness allow to preserve fit-up and dimensional tolerances.

You’ll get single pass benefits: reduced distortion, faster cycle time, and more consistent metallurgy. Choose electrode size by the rule of thumb—1 amp per 0.001-inch diameter—to obtain the penetration needed in one pass and enable efficient welding.

Train to control travel speed, arc length, and heat input so a single bead achieves full fusion without undercut.

- Use larger electrodes to decrease pass count and cumulative shrinkage.

- Verify amperage-to-electrode ratio for expected penetration and bead profile.

- Monitor interpass temperature even when single-pass is planned.

- Practice consistent technique to improve bead appearance and mechanical properties.

Presetting, Clamping, and Using Jigs to Hold Alignment

You should preset parts—prebend or prespring—so shrinkage forces are countered and final geometry meets tolerances.

Clamp components securely before welding and use strongbacks or fixed stops to keep joint alignment stable during all passes.

Where heat input is critical, employ water-cooled jigs to extract thermal energy and maintain dimensional control throughout the weld cycle.

Preset for Counter-Shrinkage

When you pre-bend or prespring parts to offset expected contraction, clamp them in purpose-built jigs so the assembly stays within tolerances as weld heat is applied and withdrawn.

You’ll use preset techniques for precise shrinkage management: measure anticipated contraction, apply calculated prebend, and secure components in fixtures that locate datum points rigidly.

Trial welds validate preset amounts and reveal adjustments. Use jigs that provide thermal control—water-cooled where needed—to remove heat and stabilize geometry.

Document preset values and fixture settings for repeatability. Follow weld procedure specifications and tolerances; record deviations and corrective presets.

- Prebend/prespring to counter predicted linear shrinkage.

- Datum-based jigs lock critical alignment.

- Trial welds confirm preset magnitude.

- Thermal jigs (water-cooled) reduce distortion.

Clamp Before Welding

Clamp the assembly in its jig before striking the first tack to lock datum points and neutralize thermal movement during welding.

You’ll select clamp types based on fixture geometry, load direction, and material thickness: C-clamps for simple holds, toggle clamps for repeatability, and magnetic or strap clamps for thin sections.

Position clamps to oppose anticipated shrinkage vectors and minimize lever arms that produce distortion. Use progressive clamping techniques — pre-tension, tack-weld, then retighten — to maintain alignment as heat cycles.

Design jigs to register primary datums and allow access for welding sequence control. Inspect for slippage after each pass and document clamp locations and torque values per procedure.

Proper clamping techniques reduce post-weld distortion and preserve weldment integrity.

Use Water-Cooled Jigs

After securing the assembly in its jig, consider water-cooled jigs to actively remove heat from the welding area and hold alignment under thermal load. You’ll control thermal management by routing water circulation through channels that contact fixture surfaces, extracting heat and minimizing distortion.

Clamp-to-jig interfaces must be rigid, repeatable, and referenced to datum points so parts can’t shift during welding. Implement monitoring for inlet/outlet temperature and flow to enforce standards and verify consistent cooling performance.

- Design channels to maximize surface contact and uniform water circulation.

- Use hard stops and repeatable clamps tied to inspection datums.

- Verify flow rates and ΔT to confirm thermal management targets.

- Document procedures for setup, purging, and leak testing before welding.

Stress Relief, Peening, and Thermal Control Methods

Although you’ll rely primarily on sound welding technique to limit distortion, targeted stress-relief practices such as controlled peening and thermal stress relief are essential tools for managing residual stresses and shrinkage forces in critical weldments.

You’ll apply peening techniques by systematically striking the bead to stretch and thin it, reducing localized stress concentration and minimizing distortion, but you’ll avoid root beads and final passes to prevent cracking or surface damage.

For thermal relief, you’ll use controlled heating to an appropriate temperature, hold to permit stress redistribution, and cool gradually per material-specific procedures to improve alignment and mechanical performance.

Both methods address shrinkage forces; you’ll select and document processes per applicable codes and material specifications.

Practical Tips for Arc Length, Travel Angle, and Current Settings

When you control arc length, travel angle, and current precisely, you’ll prevent common defects and produce consistent, code-compliant welds; you’ll maintain an ideal arc length equal to the electrode diameter, set current at 1 A per .001″ diameter, and place the puddle in the leading third for full penetration.

Apply a 0–15° drag/backhand travel angle for flat and overhead positions and limit weave to twice the electrode core diameter on heavy sections.

- Keep arc length = electrode diameter to avoid erratic arcs and improve bead appearance.

- Set amperage: 1 A per .001″ electrode diameter for proper fusion.

- Use 0–15° travel angle (drag/backhand) toward travel direction for control.

- Weave no wider than 2× core diameter; keep speed so pool leads one-third.

Frequently Asked Questions

How Do Different Filler Metals Affect Distortion?

Different filler metals change heat input and solidification shrinkage, so you’ll select filler metal selection to control distortion factors like thermal expansion, cooling rate, and weld metal strength; you’ll follow specs to minimize residual stresses and warpage.

Can Welding Sequence Change Metallurgical Properties?

Like tuning a piano, you’ll change harmonics: welding sequence can alter metallurgical properties by modifying thermal cycles, cooling rates, phase transformations and residual stresses, so you must plan weld order per code, material, and heat input.

How Does Preheating Alter Residual Stress Patterns?

Preheating alters residual stress patterns by reducing thermal gradients and slowing cooling rates; you’ll get preheating benefits like stress reduction, refined microstructures, lower transformation stresses, and improved ductility, meeting welding procedure specification limits.

When Is Vibration Stress Relief Preferable to Thermal Methods?

I’d choose vibration stress relief when tight tolerances, low thermal distortion, or complex assemblies demand it; like a clockmaker using gentle taps, vibration techniques complement stress analysis, meeting standards while avoiding heat-induced metallurgical changes.

Do Shielding Gas Choices Influence Shrinkage?

Yes — you’ll see shrinkage changes: gas composition alters arc stability and heat input, while flow rate affects shielding integrity and cooling rates; control both to meet welding procedure specifications and minimize distortion within qualified limits.

Conclusion

You’ve got the tools and techniques to cut distortion like a surgeon—right-size welds, plan sequences around the neutral axis, use intermittent/backstep patterns, and minimize passes with proper electrode sizing. Clamp, jig, and preset fixtures to hold alignment, then control heat with peening, stress relief, and measured thermal cycles. Dial in arc length, travel angle, and current per procedure. Follow these standards-driven steps consistently to guarantee predictable, repeatable, and dimensionally stable welds.