You’ll cut roller costs by switching to inertia friction welding because it joins near‑net blanks and dissimilar metals without filler or shielding gas, slashes cycle times from ~15 minutes to under 2 minutes, and trims material waste by 40–70%. The solid‑state process yields forged‑quality, repeatable joints with less machining, lower labor, and smaller safety factors. It also simplifies supply chains and reduces inventory. Keep going and you’ll find specifics on savings, equipment, and material limits.

What Is Inertia Friction Welding and Why It Matters for Rollers

Inertia friction welding (IFW) is a solid‑state joining process that uses controlled rotation and axial force to forge parts together without filler or gas, producing full‑strength, 100% integral joints ideal for industrial rollers.

You’ll find IFW matters because it delivers consistent joint applications with minimal ancillary inputs: no filler, no shielding gas, and limited pre‑weld prep. You’ll cut cycle times dramatically — from about 15 minutes to roughly 2 minutes per roll — which translates directly into labor savings and higher throughput.

By joining dissimilar metals and enabling near‑net shape components, IFW reduces material consumption by 40–70%, lowering part cost and inventory waste. The resulting joints provide full‑strength continuity across the interface, giving rollers predictable mechanical performance and long service life.

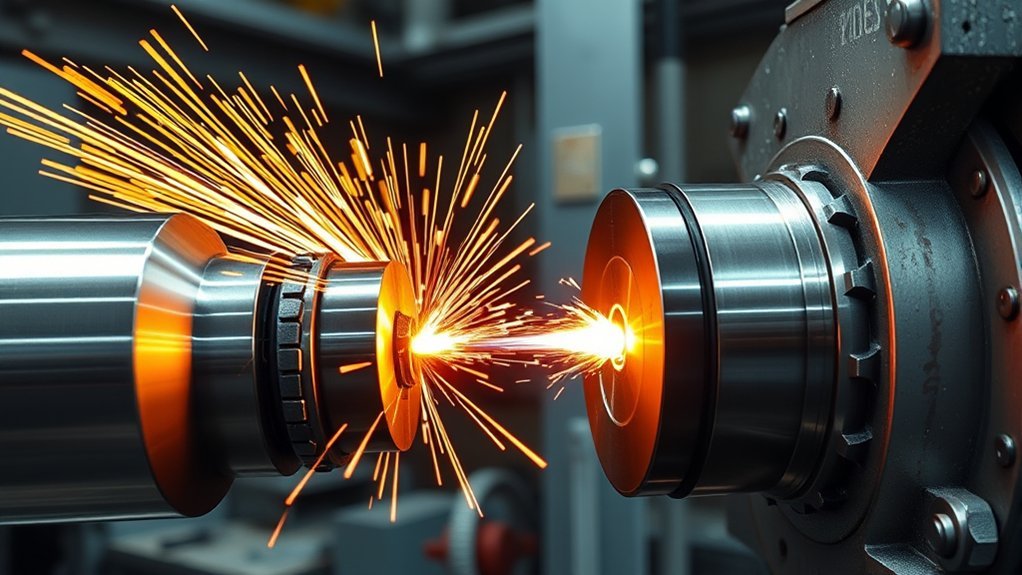

How the Inertia Friction Welding Process Works Step by Step

You’ll see how stored kinetic energy and controlled motion drive the weld by first spinning a flywheel to preload rotational energy.

Then you’ll follow the welding sequence: bring the rotating and static components into contact, apply axial force to convert kinetic energy into frictional heat, and allow plastic displacement to form the bond in 15–45 seconds.

Finally, you’ll note how the short cycle and near-net shaping cut material waste and shrink assembly time from about 15 minutes to roughly 2.

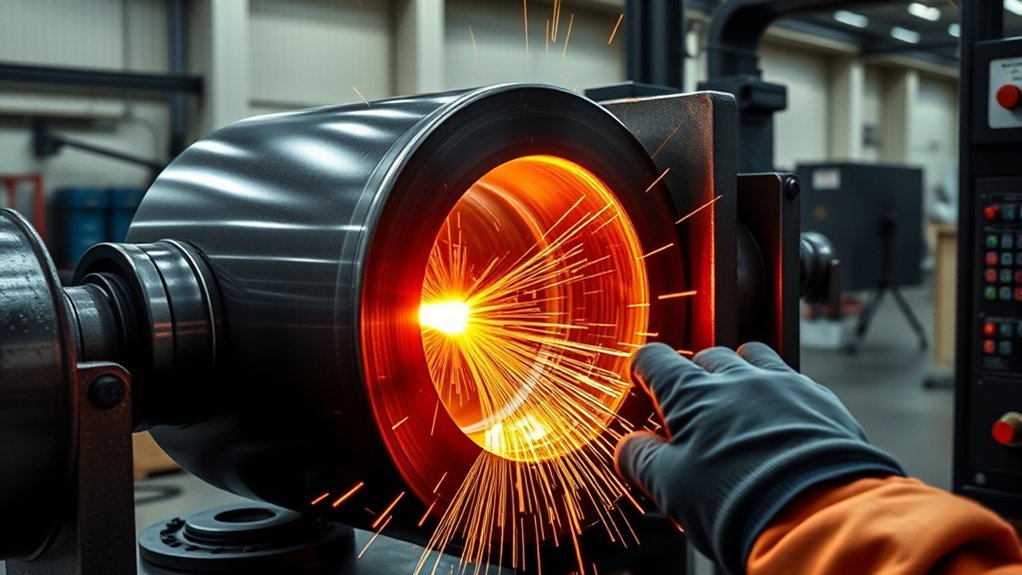

Energy and Motion

Because the flywheel stores the kinetic energy needed for bonding, the process starts by spinning it to a precise speed so you’ve got consistent, controllable energy on tap.

You rely on kinetic energy and engineered friction dynamics to convert rotational motion into localized heat and lateral force. With the flywheel stabilized, you bring the static component into contact with the rotating component; friction produces rapid heating and plastic displacement at the interface without filler metal.

The cycle’s brief duration—typically 15–45 seconds—delivers required energy while limiting the heat-affected zone, so base properties remain intact.

You control energy input and contact pressure to tune joint quality, reproducibility, and throughput, reducing rework and keeping production costs low.

Welding Sequence Steps

Having stabilized the flywheel and controlled the kinetic energy and contact pressure described earlier, you proceed through a tightly sequenced set of steps that convert stored rotation into a forged joint.

You first spin the flywheel to the predetermined speed, storing the kinetic energy needed for welding techniques used in industrial applications.

You initiate contact by advancing the static component into the rotating one, producing frictional heat that plasticizes the interface.

As the flywheel decelerates, you apply axial forging force to consolidate the softened material, forming a homogeneous bond without filler.

The full cycle runs 15–45 seconds, minimizing cycle time.

Finally, you inspect and test the joint for integrity and 100% contact-area weld quality to meet industry standards.

Material Savings: Reducing Waste by 40–70

You’ll see up to 40–70% less material waste because inertia friction welding produces near‑net blanks that match final geometry more closely.

That precision cuts required machining and the volume of scrap turned away from rollers.

With less material removed, you lower raw‑material use and downstream handling costs.

Near-Net Blank Production

Near-net blank production via inertia friction welding cuts material waste by roughly 40–70% compared with traditional machining, since you start with a shape that closely matches the final roller and need far less bulk removal.

You gain near net benefits immediately: raw material purchase drops, handling and stock costs shrink, and your scrap stream is minimized.

By supplying blanks that require limited finishing, you improve production efficiency—shorter cycle times, fewer tool changes, and lower machining energy.

The welding process also lets you combine different metals, so you can substitute lower-cost alloys where appropriate without compromising critical surfaces.

Collectively, these factors reduce per-piece material cost, streamline workflow, and support greener manufacturing through considerably reduced material consumption.

Less Machining Scrap

Because inertia friction welding joins near-net components without filler and cuts out extensive machining, you’ll see machining scrap fall sharply—typically 40–70% less material discarded versus conventional machining.

You’ll use near-net blanks that require minimal final turning, so raw material usage can be four times lower than traditional methods.

The process produces full-strength joints without filler, reducing offcuts and rejected parts.

These welding advantages translate directly into measurable cost efficiency: lower material purchase, reduced handling and disposal fees, and fewer rework cycles.

You’ll also lower environmental impact by cutting waste streams.

For roller production, this means tighter inventory control, predictable yield improvements, and a clearer return-on-investment calculation centered on reduced scrap and streamlined downstream machining.

Cutting Cycle Time and Increasing Throughput

When manufacturers switch to inertia friction welding, they’ll cut assembly time per roller from about 15 minutes to roughly 2 minutes, boosting throughput and enabling roughly ten times the output versus traditional welding.

You’ll realize clear welding benefits: a 50–60% reduction in cycle time and near-net shape parts that slash downstream machining.

You can plan capacity precisely—what once took many hours now yields about 50 rollers in the same window, so floor space and labor costs per part drop sharply.

Because the process minimizes material loss and secondary operations, each machine run finishes faster and with fewer touchpoints, reducing bottlenecks and work-in-progress inventory.

On the production-efficiency front, shorter cycles let you shift from batch to continuous workflows, improving takt time and responsiveness to demand.

You’ll also lower per-unit energy and overhead allocations, so throughput gains translate directly to unit-cost reductions and faster return on capital for roller manufacturing investments.

Joining Dissimilar Metals for Lightweight, High-Performance Rollers

Although joining different alloys can be challenging, inertia friction welding lets you combine lightweight cores with wear-resistant sleeves in a single, robust bond that preserves each material’s mechanical properties.

You can join dissimilar metals to produce lightweight rollers that cut material costs 40–70% by replacing costly alloys with lower-cost alternatives while meeting performance thresholds.

The process uses near-net shape components, minimizing waste and trimming machining time by up to 15%, so you speed production without extra finishing.

Because the welds eliminate filler and gas, you reduce consumables and emissions, lowering both expense and environmental impact.

You maintain the original metallurgy at the interface, so strength and durability are retained and component life improves.

In practice, you optimize resource allocation by pairing a low-density core for mass reduction with a hardened sleeve for wear resistance, achieving high-performance rollers at lower total cost.

This targeted material pairing delivers efficiency gains across manufacturing and in-service operation.

Quality and Strength: Forged-Quality Welds and Repeatability

You’ll get forged-quality joint integrity with inertia friction welding, achieving full-strength bonds across the contact area without filler.

The process limits heat-affected zones and delivers extreme consistency, so each roller meets the same mechanical specifications.

That repeatability—backed by industry standards and faster cycle times—reduces variability and improves overall reliability.

Forged-quality Joint Integrity

Integrity matters: inertia friction welding delivers forged-quality joints that give you 100% contiguous weld integrity across the contact area, producing strength and fatigue resistance superior to fusion methods.

You get predictable joint performance that withstands cyclic loads common in rollers, letting you specify smaller safety factors and reduce material costs.

The solid-state process removes filler and gas variables, yielding cleaner microstructures and consistent metallurgical bonding—even for dissimilar metals—so optimized material selection won’t compromise integrity.

Machine-controlled parameters enhance manufacturing efficiency by minimizing rework and nonconformances, and compliant procedures (AWS C6.1, ISO 9001:2015) support clear inspection criteria.

Consistent, Repeatable Results

When you need uniform, forged-quality strength across every roller, inertia friction welding delivers machine-controlled, solid-state bonds that eliminate filler and gas variables and produce 100% contiguous joint integrity. You get consistent weld quality because the process is driven by precise inertia and force profiles, removing operator variability. Cycle times drop 50–60%, so you improve production efficiency while keeping strength and cleanliness high. Near-net components reduce post-weld machining, reinforcing repeatability from part to part. Data-driven parameter control means each joint meets the same mechanical criteria, lowering inspection burdens and scrap.

| Benefit | Impact |

|---|---|

| 100% joint integrity | Predictable service life |

| No filler/gas | Cleaner microstructure |

| Shorter cycle time | Higher throughput |

| Near-net shape | Less machining, tighter tolerances |

Equipment Capabilities: Welder Sizes and Work Envelopes

Three Inertia Group models cover a wide range of roller sizes and work envelopes, letting you match welder capacity to part geometry and production needs.

You’ll pick the Inertia Welder 120 for small shafts (0.25”–1.2” dia., 3.5” x 21.25” envelope), the 180BX for medium parts (0.5”–1.8” dia., 4” x 144” envelope) and the 250B for large rollers (1.0”–10.0” dia., 10” x 104” envelope).

The 180BX’s open-end design gives nearly infinite weld length, so you can handle long assemblies without custom fixturing.

With its open-end design, the 180BX enables virtually unlimited weld length for long assemblies—no custom fixturing required.

Each machine delivers high-strength joints across diverse metal combinations, enabling near-net-shape components that cut post-weld machining.

By aligning welding technology to specific geometries, you’ll minimize material waste and setup time.

The result is higher production efficiency: fewer operations, less material removed, and versatile part designs.

Choose the model whose work envelope matches your largest and most frequent parts to maximize throughput and flexibility.

Real-World Cost Reductions in Roller Manufacturing

Matching the right Inertia Group welder to your parts not only streamlines setup but also reveals substantial cost savings across production.

You’ll see dramatic labor reductions: assembly time drops from about 15 minutes to roughly 2 minutes per roll, translating directly into lower hourly labor expense and higher throughput.

A targeted cost analysis shows material savings too — near‑net blanks cut scrap and machining by 40–70% versus conventional methods.

You’ll also eliminate filler metals and shielding gases, simplifying supply chains and reducing per‑part consumable costs.

Using dissimilar metals strategically reduces overall material spend by 15–35% while improving performance where it matters.

OEM reports confirm consistent quality gains and less scrap, which further improves manufacturing efficiency and lowers warranty or rework liabilities.

Taken together, these factors compress unit cost, shorten lead times, and improve your plant’s competitive position without adding process complexity.

Limitations and Material Considerations for Roller Applications

Because inertia friction welding depends on plastic flow at elevated temperatures, you’ll need to screen materials and geometries up front: brittle alloys (for example cast iron or leaded bronzes >0.3% Pb), metals with low ductility or persistent brittle phases like graphite and MnS, and extremely hard substrates often won’t forge satisfactorily or will crack during upset.

Inertia friction welding requires pre-screening materials and geometries—avoid brittle alloys, low-ductility metals, and overly hard substrates.

You’ll also face welding challenges tied to joint type and part geometry: inertia friction welding is optimized for axial butt welds, so you can’t rely on angled or complex orientations without redesign. For roller applications you must evaluate ductility, hardenability, and the presence of inclusions that nucleate cracks under compressive shear.

- Conduct material selection based on high-temperature malleability and inclusion content.

- Quantify geometry limits: section ratio, length-to-diameter, and upset volume.

- Test combinations for interfacial integrity and residual stress.

- Reject candidates with persistent brittle phases or excessive hardness.

Make decisions early to avoid scrap, control welding challenges, and guarantee robust, repeatable roller joints.

How to Partner With a Friction Welding Specialist for Roller Production

When you partner with a friction welding specialist, plan the relationship around measurable goals — cost reduction, cycle-time improvement, and material efficiency — so you can evaluate proposals against clear KPIs. You’ll focus on cost effective collaboration, defining target savings (15–35% material reduction via near‑net blanks), cycle-time cuts (from ~15 to ~2 minutes per roller), and waste reduction (up to 70% through optimized metal combinations). Assess technical capabilities: range of material pairings, quality control, and environmental benefits (no filler or gas emissions). Demand pilot runs, sample reports, and agreed acceptance criteria tied to industry standards. Negotiate volume pricing, lead times, and continuous improvement clauses that capture friction welding advantages. Monitor KPIs regularly and use data to scale production or adjust specs. A clear contract with performance metrics, testing protocols, and escalation paths guarantees predictable quality, lower cost-per-roller, and sustained operational gains.

| Objective | Measure |

|---|---|

| Cost savings | % material reduction |

| Cycle time | Minutes per roller |

| Waste | % reduction |

| Quality | Compliance tests |

Frequently Asked Questions

What Safety Precautions Are Unique to Inertia Friction Welding Operations?

You must enforce specialized safety training, lockout/tagout, and thermal/rotational guards; keep strict equipment maintenance logs, inspect flywheels, bearings, and clamps; monitor for sparks, control energy storage, and guarantee emergency shutdowns are tested.

How Does Inertia Friction Welding Affect Roller Surface Finish and Post-Process Machining?

Inertia friction welding preserves good surface quality at the joint, reducing defects; you’ll need minimal post-process machining, so machining efficiency improves, cutting cycle time and tool wear while ensuring consistent roller geometry and finish.

What Inspection and Non-Destructive Testing Are Recommended for Welded Rollers?

You should use visual inspection, dye penetrant, ultrasonic and radiographic testing methods, plus hardness mapping and dimensional checks to verify weld quality; document results and perform periodic NDT to guarantee consistent roller performance.

Are There Long-Term Fatigue or Creep Concerns for Inertia-Welded Roller Joints?

Yes — you’ll see excellent fatigue resistance in properly processed inertia-welded joints, and creep behavior is minimal at moderate temperatures; monitor heat treatment, residual stresses, and service temperatures to prevent long-term degradation.

What Lead Times and Logistics Are Typical When Outsourcing Inertia Friction Welding?

Coincidentally, you’ll see lead times typically range two to six weeks; you’ll factor in tooling, scheduling, and transport. You’ll mitigate logistical challenges via consolidated shipments, clear specs, buffer stock, and vendor-capacity verification to avoid delays.

Conclusion

You’ll cut costs and boost throughput by switching to inertia friction welding for rollers: it slashes raw-material waste, trims cycle time, and joins dissimilar metals for lighter, stronger assemblies. You’ll need proper equipment and metallurgical oversight, and it isn’t magic—limitations exist for some alloys. Partner with a specialist to size welders, validate processes, and quantify savings. Think of it as a steam engine-era innovation refit for modern manufacturing efficiency.