You’ll typically pay between about $3,000 and $25,000 for welding trade school depending on program length and school. Short certificate courses run roughly $3k–$10k, yearlong diplomas $5k–$15k, and two‑year associate degrees $10k–$25k. Expect extra costs for gear, books, testing and living expenses that can add $100–$15,000. Financial aid, scholarships and payment plans often lower your out‑of‑pocket share, and the next sections explain how to compare total value.

Typical Price Ranges for Welding Trade School Programs

You’ll typically pay between $5,000 and $15,000 for a welding trade school program, though costs vary by credential and institution.

You’ll find certificate programs often cost $3,000–$10,000, while diploma tracks usually fall in the $5,000–$15,000 range.

If you pursue an associate degree, expect two-year programs that can reach $10,000–$25,000.

Remember to budget for additional trade school expenses: safety gear, welding machines, and books can add $100–$2,500 to your total.

Specialized training, such as advanced underwater welding, can push welding program costs above $15,000 because of equipment and instructor needs.

Use these ranges to compare programs and estimate your total outlay before you enroll.

Types of Institutions and How Costs Differ

Those price ranges give a baseline, but where you enroll has a big effect on what you actually pay.

If you pick a community college, you’ll typically pay closer to $5,000 for a two-year welding program; those schools often include general education and may offer lower in-state tuition.

Trade schools focus on hands-on vocational training and commonly charge between $5,000 and $20,000 depending on equipment and specialization.

Short certificate programs cost $3,000–$10,000 and let you enter the workforce faster.

Highly specialized tracks, like underwater welding, can exceed $15,000 due to specialized gear and instruction.

Always confirm program accreditation and local fees so you compare true cost across welding schools and avoid surprises.

Program Lengths and What You Get for Your Money

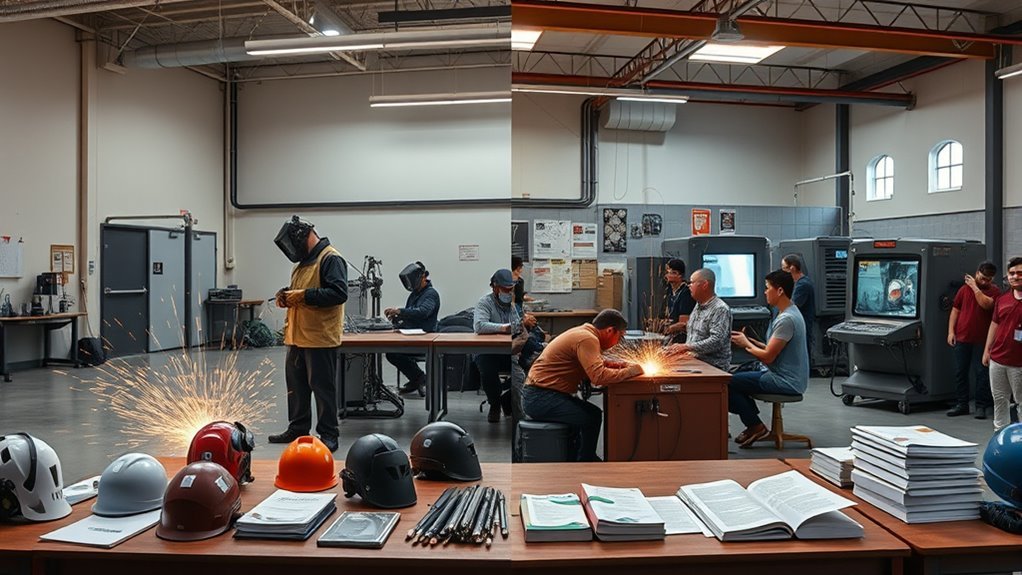

When you compare certificates to degrees, you’re weighing shorter, skills-focused training against longer programs that add general education and broader credentials.

Certificate courses (weeks to months, $3k–$10k) usually concentrate on hands-on welding skills and a job-ready certificate.

Associate and diploma tracks (one to two years, $5k–$25k) cost more but often include extra lab time, general coursework, and credentials that can boost hiring and pay.

Certificate vs. Degree

Although shorter programs get you into the job market faster, the length and cost of welding education directly affect the depth of training and career options you’ll have:

certificate programs take weeks to months and cost roughly $3,000–$10,000 for essential entry-level skills; diploma programs run about a year for $5,000–$15,000 and offer more hands-on practice; associate degrees take two years, cost $10,000–$25,000, and add general education alongside specialized welding; and bachelor’s programs, at four years and $40,000–$100,000, mix advanced welding, engineering, and business concepts that can lead to higher-paying roles.

You’ll weigh certificate benefits like speed and lower cost against degree advantages such as broader knowledge, credential strength, and longer-term earning potential.

Choose based on time, budget, and career goals.

What’s Included

Now that you’ve weighed certificates against degrees, let’s look at what each program actually gives you for the time and money.

Certificate programs run weeks to months, cost roughly $3,000–$10,000, and focus on core welding techniques with intensive hands-on labs; curriculum details emphasize flux-core, MIG, TIG, basic safety, and shop practice, producing quick program outcomes like entry-level readiness and basic certifications.

Diploma options typically take about a year, cost $5,000–$15,000, and add more shop hours and specialized modules.

Associate degrees span two years, $10,000–$25,000, and combine technical training with general education.

Expect extra expenses for materials and safety gear ($100–$2,000).

All formats aim for practical skills and industry-recognized certifications to boost employability.

Mandatory and Optional Additional Expenses

Budgeting for welding trade school means accounting for more than just tuition; you’ll also need to cover mandatory costs like materials and safety gear ($100–$500), potential equipment purchases such as a personal welding machine ($500–$2,000), and certification test fees (typically $300–$550 each).

While keeping in mind that living expenses can add another $5,000–$15,000 per academic year and push the total from a basic $5,000–$30,000 tuition up substantially.

You should list mandatory costs first so you don’t underestimate. Then decide which optional expenses make sense: a personal machine for practice, upgraded PPE, reference books, or travel for externships.

Track one-time purchases versus recurring fees, and factor living costs into monthly budgets to see true program cost.

Certification, Licensing, and Testing Costs

If you want to maximize hiring prospects, plan on paying separately for certification and testing—most welder exams run $300–$550 each and often aren’t covered by school tuition.

You should budget for American Welding Society or similar Certified Welder exams because testing requirements vary by employer and specialty. Schools may offer prep and specific certifications that validate skills and deliver clear certification benefits, especially in pipe, structural, or stainless welding.

Even in states without licensing, like Illinois or Missouri, employers often prefer certified welders, so certification can improve job opportunities and credibility.

Expect additional fees for retests, paperwork, or specialty endorsements. Include these costs alongside tuition and materials so you won’t be surprised when you’re ready to take the exam.

Financial Aid, Scholarships, and Payment Options

Having accounted for certification and testing fees, you’ll want to explore financial aid, scholarships, and payment plans to keep overall costs manageable.

Federal grants and low-interest loans are primary financial aid strategies; apply early for FAFSA to see what you qualify for.

Check with schools about GI Bill® eligibility if you’re a veteran or dependent—this can cover a large portion of tuition.

Look for scholarship opportunities from professional associations, private companies, and welding programs; competitions and high school senior status often increase chances.

Many schools offer payment plans that let you spread tuition in installments, reducing upfront pressure.

Combine grants, scholarships, veteran benefits, and payment plans to minimize borrowing and lower total program costs.

Comparing Return on Investment by Industry and Location

Because industry and location directly shape your earning potential, you should weigh program costs against where and in what sector you’ll work. Consider ROI factors like program cost ($5k–$20k+), program length, and Industry demand in your region. Shorter certificates get you working sooner; community college programs (~$5k) lower upfront cost and still lead to stable wages. High-paying sectors — oil and gas, shipbuilding, aerospace — offer median wages around $47,540, boosting ROI and justifying pricier training if demand is strong. Geography matters: regions with concentrated industry demand produce higher wages and placement rates, speeding payback. Use the table below to compare typical scenarios and estimate how location plus industry affect your payback timeline.

| Scenario | Typical outcome |

|---|---|

| Community college, local demand | Lower cost, steady ROI |

| Advanced program, high-demand region | Higher cost, faster payback |

How to Choose the Most Cost-Effective Welding Program

You should add up tuition, program length, and all extra fees so you know the true total cost instead of just the sticker price.

Compare schools side-by-side — community colleges often run $5,000–$15,000 while trade schools can exceed $20,000, and certificate vs. diploma timelines affect price.

Then evaluate scholarships, grants, and loan options to lower your out‑of‑pocket expense and weigh that against local job placement and wage prospects.

Compare Total Costs

Start by tallying the real total cost of each program so you can compare apples to apples: list tuition, fees, equipment and safety gear, materials, testing and certification fees, and an estimate for living or transportation expenses.

Add certificate, diploma or associate costs—programs range roughly $3,000–$25,000, with total outlays often $5,000–$30,000 once you include extras. Include a realistic equipment and living buffer of $500–$15,000.

Then weigh program quality and hands-on training: higher upfront cost can yield faster certification and better job placement, boosting long-term welding salaries.

Rank programs by total cost per expected outcome (skills, certifications, placement rate). That lets you choose the option with the best return without overlooking hidden expenses.

Evaluate Funding Options

Now that you’ve tallied true program costs and ranked value by outcomes, look at how you’ll pay for the option that gives the best return.

Start with federal loans and grants—they usually carry lower interest and favorable repayment terms; grants don’t need repayment, so prioritize them.

Compare community college tuition (~$5,000) to trade school costs ($5,000–$20,000) and factor in $500–$2,000 for gear, tools, and certification.

Seek private scholarships from professional associations and companies to cut out-of-pocket expenses. If eligible, use institutional payment plans to spread costs without high interest.

Add projected loan payments to your budget and choose the program whose net cost, after scholarships and grants, yields the strongest return on investment.

Frequently Asked Questions

Can I Work While Attending Welding Trade School?

Yes — you can work while attending welding trade school. You’ll find part time jobs with flexible schedules, and you’ll need to balance shop hours, homework, and safety training to keep progress steady and avoid burnout.

Are Online Welding Courses Accepted by Employers?

Yes — some employers accept online welding courses, but you’ll need strong online course credibility, hands-on certifications, and relevant experience; employer preferences vary, so prioritize accredited programs, documented practical training, and industry-recognized credentials.

What Health Risks Come With Welding Training?

Like a storm cloud, welding training brings hazards: you’ll face respiratory hazards from fumes and gases, burn and eye injury risks, noise and UV exposure; practice welding safety, use ventilation, respirators, gloves, and eye protection.

Do Employers Reimburse Tuition After Hiring Graduates?

Yes — many employers offer tuition reimbursement and employer incentives after hiring graduates; you’ll often need to meet service time, performance, or certification conditions, so review contracts carefully and confirm eligibility before assuming reimbursement.

How Quickly Do Welding Certifications Expire?

Ironically, your welding certification duration often already feels short: most certifications expire in one to three years. You’ll need to follow the renewal process — retesting, continued training, or employer-sponsored refreshers — to stay qualified.

Conclusion

You’ll see welding school costs vary widely, but don’t assume higher price equals better outcome. Investigate the theory that expensive programs guarantee superior jobs: compare curricula, instructor experience, hands-on hours, and employer connections instead of sticker price. Factor certifications, tools, and living expenses, then weigh local industry demand and average wages. Pick the program that gives the necessary skills, credible credentials, and clear employer pathways — that’s the real predictor of return on investment.