You’ll typically pay $50–$65 per hour for general welding, with TIG, FCAW, and certified structural work running $75–$200/hr depending on skill and standards required. Expect minimum charges of $40–$75 to cover setup and travel, plus flat equipment-initiation fees near $60 and separate consumable, gas, and material charges. Mobile jobs add travel/setup fees; complex alloys and inspections raise rates. Continue for a breakdown of process-specific, material, and overhead cost drivers.

Welder Hourly Rates and Minimum Charges

Hourly welder rates typically fall between $50 and $65 nationwide, but specialized work can reach $200 per hour. Many shops enforce a minimum charge—often about $75 for the first hour—to cover setup and travel.

You’ll classify welding service types (MIG, TIG, specialty) and apply consistent pricing strategies: set a flat equipment-initiation fee (commonly $60) then bill an hourly rate (often $60) or use procedure-based flat pricing.

For basic MIG work you’ll expect minimums near $40; TIG minimums commonly start at $75 due to material and skill differentials.

You’ll document minimum service fees, clearly state start-time billing, and standardize rate cards to align with shop standards and customer expectations, ensuring transparent, reproducible invoicing.

Factors That Influence Welding Costs

Because multiple variables directly affect price, you should evaluate labor, materials, complexity, consumables, and location when estimating a welding job.

You’ll assess welder hourly rates (typically $50–$65; specialized work up to $200/hr) against the project scope to determine baseline labor cost. Choose welding techniques that match joint design and base metal—technique affects time, qualification level, and inspection requirements.

Material selection alters preparation, fixturing, and heat control; higher-cost alloys often need slower travel speeds and specialized procedures. Consumables and additional supplies increase unit cost proportional to usage.

Finally, geographic location modifies labor and overhead: urban markets commonly demand higher rates. Use standards-based estimating, quantify hours per procedure, and include contingency for complexity and inspection.

Material Expenses and Consumables

When budgeting welding work, you should account for consumables and supplies—welding rods, grinding wheels, sanding stones—and their replacement frequency.

Factor in gas and welding wire costs explicitly (for example, a 30 lb roll of wire may be ~$40 and flux can run $120–$150 every 1.5–2 weeks), and remember clients usually cover full material purchases even if not fully consumed.

Also consider metal type and market volatility, since aluminum or stainless can cost 1.5–2× steel and prices can spike during downturns.

Consumables and Supplies

Consumables like wire, flux, grinding wheels and sanding paper form a predictable and material portion of your welding budget, and you’ll typically see weekly sanding-paper costs around $64 and a 30‑lb spool of wire near $40. You must budget for sanding paper costs and welding wire pricing as recurring line items; flux, discs and replacement tips compound per-job totals. Material-selection affects consumable consumption — aluminum and stainless demand more prep and abrasive life than steel. You’re charged for full material costs even if you use partial quantities. Price volatility can shift a component from routine to significant exposure, so apply unit-cost tracking and reorder thresholds. Use the table below for quick reference.

| Item | Typical Unit Cost |

|---|---|

| Sanding paper (weekly) | $64 |

| 30 lb wire spool | $40 |

| Flux/grinding discs | $10–$50 |

Gas and Welding Wire

You’ve already budgeted for abrasives and tips; now quantify the gas and welding‑wire line items that drive routine operating costs.

You’ll typically buy a 30‑lb roll of welding wire at about $40 each; track roll counts per project to allocate costs precisely.

Flux and shielding gas consume more: expect $120–$150 every 1.5–2 weeks depending on throughput and process (MIG/TIG/flux‑core).

Monitor gas prices regularly, since fluctuations directly alter per‑hour material rates.

Include full consumable markup in customer estimates, because billing commonly covers complete items even if partially used.

Implement periodic inventory audits and per‑job material tickets to standardize unit costs, reduce waste, and produce verifiable, standards‑based budget projections for welding operations.

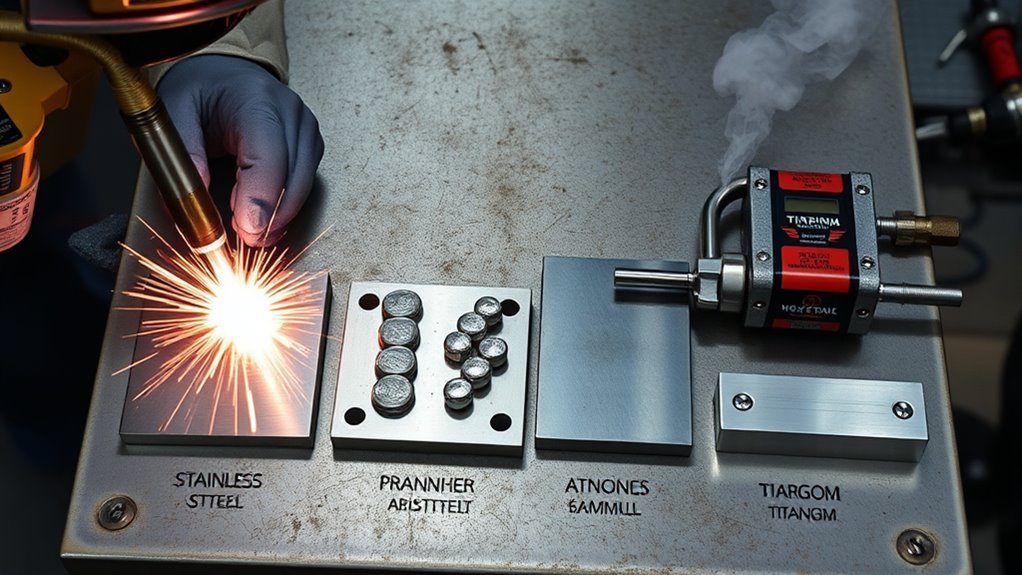

How Metal Type Affects Pricing

Because different metals demand different materials, techniques, and skilled labor, the metal you choose has a direct and often predictable impact on welding costs. You’ll evaluate welding techniques and metal properties to estimate expenses: steel is cheapest, aluminum and stainless typically raise costs by 1.5–2×, and exotic alloys or thicker sections need specialized processes and higher labor rates. Consumables (gases, rods) vary by metal and add to totals. Market volatility affects steel pricing—e.g., a 25-foot stick of 2×6 14-gauge can run $44–$50, spiking to $125 in downturns—so budget contingencies.

| Metal | Relative Cost | Notes |

|---|---|---|

| Steel | Low | Widest availability |

| Aluminum | 1.5–2× | Requires different filler, technique |

| Stainless/Alloys | 1.5–2×+ | Higher consumables, skilled labor |

Typical Costs for Repairs and Small Jobs

You’ll typically encounter minimum service fees—often $40 for basic shop MIG work, $75 for TIG starts, and $75 for the first hour of mobile calls—that cover setup and travel.

Expect typical hourly ranges to produce total small-repair costs from about $124 to $486, with a national average near $298.

Be aware material cost add-ons (aluminum versus steel, filler wire, shielding gas) will measurably raise estimates based on complexity and consumable usage.

Minimum Service Fees

Most mobile welding services set a clear minimum fee—typically about $75 for the first hour—to cover travel, setup, and basic overhead; expect smaller bench MIG repairs to start around $40 and TIG work to begin near $75 due to higher consumable and setup costs.

You’ll use welding service comparisons and pricing transparency to select providers that match your tolerance for diagnostic estimates versus fixed minimums.

Standards-focused notes: initial equipment initiation is often a $60 flat charge, with an additional $60 hourly thereafter; small jobs get time-and-materials quotes after visual assessment.

- Confirm the stated minimum and what it covers (travel, setup, diagnostics).

- Ask if MIG vs TIG minima differ in writing.

- Require line-item estimates for consumables.

- Verify visual-assessment procedures and refund policies.

Typical Hourly Ranges

Hourly welding rates typically fall between $50 and $65 for routine repairs, with experienced technicians and urban markets pushing rates higher; specialized or limited-access work can climb to $200/hour or more due to added skill and certification requirements. You’ll see minimums: mobile services often require $75 for the first hour, basic MIG tasks start near $40, and TIG minimums are higher. Choose a provider based on required welding techniques and specific project types; complexity and certifications drive hourly escalations. Typical small-job totals range roughly $124–$486, averaging about $298 nationally. Use the table below to compare common scenarios and expected hourly expectations.

| Service Level | Typical Rate | Notes |

|---|---|---|

| Routine repair | $50–$65 | MIG/TIG basics |

| Specialized access | $100–$200+ | Certifications required |

Material Cost Add-Ons

Because material charges are often applied as whole-unit costs rather than prorated usage, expect repairs and small jobs to carry add-ons for wire, flux/gas, grinding wheels, and abrasives that can materially affect your bill.

You’ll often be billed for full rolls or bottles: a 30‑lb wire roll (~$40) and flux/gas runs ($120–$150 every 1.5–2 weeks) drive baseline costs.

Material pricing trends and welding supply sources affect estimates; steel remains the least costly base metal, while aluminum and stainless run 1.5–2× higher.

Anticipate consumable turnover—grinding wheels and sanding stones—when evaluating quotes.

- Wire: full-roll billing, price variance by alloy.

- Flux/gas: periodic consumption, supply-cycle pricing.

- Abrasives: per-piece replacement, safety-grade specs.

- Metal type: multiplier for aluminum/stainless.

Pricing for Different Welding Processes

When you compare welding processes, expect rates to reflect skill, deposition speed, and material demands; SMAW commonly runs $50–$65/hr, MIG about $75–$125/hr, TIG generally starts near $75/hr, FCAW falls in the $65–$100/hr range, and SAW typically exceeds $100/hr for heavy structural work.

Expect rates to mirror skill, deposition speed, and material demands—SMAW $50–65, MIG $75–125, TIG $75+, FCAW $65–100, SAW $100+.

You’ll select a process based on joint design, base metals, filler selection, and code requirements; weld procedures (WPS) quantify parameters you’ll control.

Consider that MIG and FCAW give higher deposition per hour, reducing labor cost on large fillets, while TIG demands slow, precise control for thin or exotic alloys.

Factor in consumables, preheat, interpass temperature, and required welding safety protocols—PPE, ventilation, and inspection standards—when comparing effective hourly cost and qualification needs.

Mobile Welding vs. Shop Rates

When you compare mobile welding to shop rates, account for travel and setup fees that commonly produce a higher minimum (often ~$75) to cover transportation and on-site rigging.

In-shop work typically yields lower minimums (around $40 for basic MIG) and better access to full-size equipment, consumables, and controlled environment standards that reduce rework risk.

On-site limitations — lighter-duty power sources, constrained fixturing, and variable material supply — directly affect hourly rates and allowable tolerances.

Travel and Setup Fees

One clear cost distinction you’ll encounter is that mobile welding carries added travel and setup fees—often creating minimum charges that start around $75 for the first hour—while shop work typically bills only labor and materials at lower hourly rates.

You should assess travel logistics and setup considerations up front: distance, vehicle fuel, equipment transport, and on-site anchoring or scaffold needs all factor into the baseline charge.

Urban markets may reduce per-mile or minimums; rural jobs usually raise them to cover time and consumables. You can sometimes supply materials to avoid supplier markups, but confirm weld-spec compliance.

Seasonal material price swings and gas cost volatility will alter estimates; request a detailed fee breakdown before authorizing work.

- Distance and time

- Equipment transport

- Consumables and gas

- Material sourcing

In-Shop Cost Advantages

1 clear cost advantage of in-shop welding is lower baseline rates: shops typically bill around $50–$65 per hour because fixed overhead spreads across many jobs and they avoid mobile travel/setup minimums.

You’ll see in shop benefits manifest as reduced hourly rates, lower material markup from bulk purchasing, and the absence of travel surcharges.

For standards-driven projects, a controlled shop environment improves throughput and minimizes rework, which lowers total cost per welded assembly.

When you compare line items, competitive pricing for in-shop work typically excludes transportation and on-site setup allowances that mobile welders add.

Choose in-shop services when project geometry, tolerances, and fixture requirements favor repeatability and cost-efficiency; reserve mobile options for when convenience outweighs the higher, itemized expense.

On-Site Equipment Limitations

Because mobile welders must transport power sources, gas, and fixtures to each site, you’re often paying a visible premium for the logistical burden compared with shop work.

You face on site challenges and equipment limitations that change pricing: mobile work typically has higher minimums (about $75 for the first hour) to cover travel, setup, and consumables.

Urban markets may compress rates; rural jobs usually cost more due to distance. You can reduce markups by supplying materials, but heavy fixtures and gas still drive a premium.

Assess job scope against shop capabilities; complex or precision work often remains cheaper and more consistent in a dedicated shop environment.

- Travel and setup time increases baseline cost.

- Gas and transport are direct add-ons.

- Site constraints limit tooling and power.

- Customer-supplied materials lower markups.

Estimating Job Time and Labor Costs

When you estimate job time and labor costs, assess the weldment’s complexity first—simple repairs will take far less time than multi-pass, tight-tolerance fabrications—since complexity directly drives hours and therefore labor expense.

You must quantify job complexity and use project estimation protocols: break the work into setup, welding, inspection, cleanup, and travel tasks.

Multiply total estimated hours by the welder hourly rate (typically $50–$125) to produce the base labor figure. Use historical data and experienced judgment to adjust for atypical access, fixtures, or rework risk.

Include minimums for setup/cleanup and remote-site travel when applicable. Regularly benchmark local shop rates to validate your rates.

Document assumptions and contingency hours to prevent underquoting and guarantee compliant, repeatable estimates.

Licensing, Insurance, and Overhead Considerations

Although regional rules and client requirements vary, you should explicitly account for licensing, bonding, insurance, and overhead when pricing welding services to guarantee compliance and protect margins.

Always factor licensing, bonding, insurance, and overhead into welding quotes to ensure compliance and protect margins

You’ll factor licensing costs and insurance requirements into every estimate so charges reflect legal obligations and risk transfer. Include equipment maintenance, consumables, and ongoing certification in overhead calculations.

In jurisdictions like California, specific permits add line-item expense. Maintain documentation to satisfy audits and client prequalification.

- Verify jurisdictional licensing costs and bonding levels, include as fixed-per-job amortized expense.

- Specify insurance requirements (general liability, professional, auto) and allocate premiums across billable hours.

- Calculate equipment depreciation, consumables, and shop utilities into hourly rates.

- Budget for recurrent training and certifications as required by standards and clients.

Tips for Getting Accurate Welding Quotes

To get an accurate welding quote, give the fabricator complete, specific information—detailed drawings or photos, material specs (grade, thickness), joint type, required weld process and position, access constraints, surface prep, and any post-weld treatments—so they can assess labor, filler, and inspection needs precisely.

Then request free estimates from multiple qualified shops, compare line-item breakdowns for labor, consumables, overhead and inspection, and confirm assumed welding parameters (amperage, travel speed).

Verify certifications and practical experience for the required codes; qualifications affect time and inspection requirements.

Communicate budget and acceptance criteria up front and maintain standardized project documentation (drawings, revisions, NDT plans).

Include welding safety requirements and any site constraints in the quote to prevent scope changes and unexpected costs.

Frequently Asked Questions

Do Welders Offer Warranties or Guarantees on Their Work?

Yes — you’ll often get welding warranties and service guarantees; reputable welders provide written, standards-based coverage specifying scope, duration, inspection criteria, repair obligations, and exclusions, ensuring compliance with codes and traceability for structural integrity and safety.

Can Welding Fumes Affect Indoor Air Quality and Health?

Yes, welding fumes degrade indoor air; they cause acute respiratory irritation, chronic lung disease, neurological effects, and systemic toxicity. You’ll monitor fume exposure, apply ventilation and PPE, and follow standards to mitigate health effects.

Are Permits Required for Structural Welding Projects?

Yes, you’ll usually need permits for structural welding projects; permit requirements enforce inspections, welding procedure specifications, qualified welder qualifications, and testing to guarantee structural integrity, compliance with building codes, and documented quality control.

How Do Seasonal Demand Fluctuations Affect Welding Availability?

Think of a calendar as a valve: you’ll see seasonal pricing spike when demand tightens, and labor availability drop during peak months; you’ll plan schedules and standards compliance to mitigate delays and maintain welding quality.

Can I Finance Large Welding or Fabrication Jobs?

Yes — you can finance large welding or fabrication jobs. You’ll evaluate financing options, integrate costs into project budgeting, use payment milestones, cost-plus clauses, and guarantee contracts reference standards, inspections, and contingency reserves.

Conclusion

When getting welding work, know that precise quoting matters: 60% of small welding shops report hourly rates between $50–$100, so expect variability. You’ll pay for minimums, travel, materials and certifications; welding stainless or aluminum typically raises costs due to filler and technique. Insist on weld procedure specifications, proof of welder qualifications, and written time estimates to avoid surprises. With those standards, you’ll compare bids objectively and control quality and cost.