Yes — you’ll usually pay more to weld aluminum than to join common thermoplastics. Aluminum demands costly capital equipment, inert gas, specialized filler and strict process control, plus higher-skilled operators and more QC, which raises both upfront and per-job costs. Plastics often need simpler tools, cheaper consumables and less operator certification, though complex polymers or cosmetic standards can flip that. Below you’ll find a breakdown of when each option becomes the cheaper, longer‑term choice.

Cost Components: Materials, Consumables, and Equipment

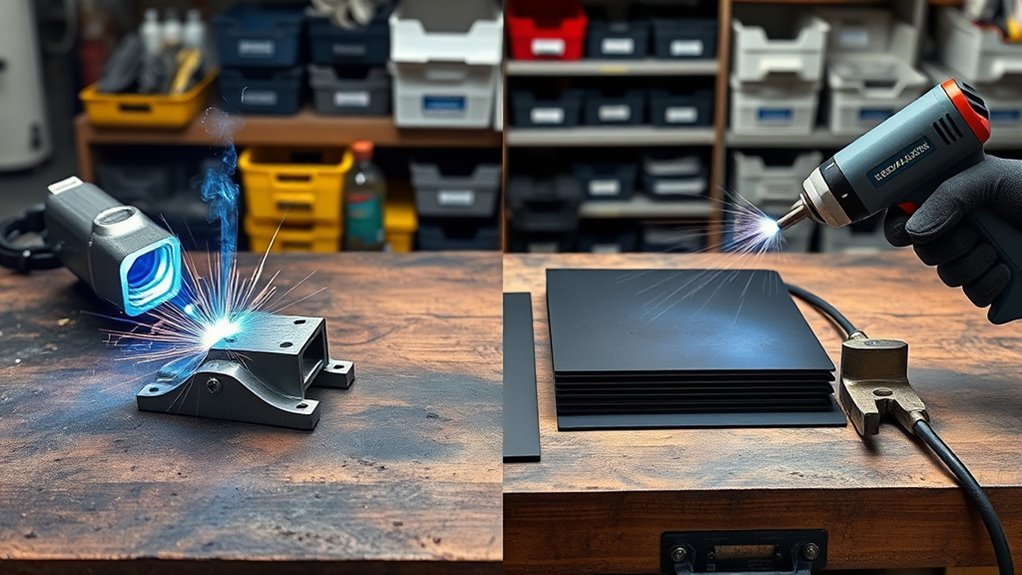

Compare the line items side by side: aluminum welding demands pricier capital equipment and ongoing consumables, while plastic welding keeps entry costs low and consumable use minimal.

You’ll evaluate material selection and cost analysis by quantifying equipment, consumables, and preparatory needs. TIG machines for aluminum often run $2,000–$3,000; plastic hot-air welders start near $50.

Aluminum requires shielding gas (argon) and specialized filler wire (e.g., 5356), increasing per-job expense, plus rigorous surface cleaning.

Plastic welding typically uses modest filler rods or adhesives and minimal prep, lowering variable costs.

Repair complexity for aluminum elevates total repair spend.

Skill, Training, and Labor Time Differences

Because aluminum demands tighter heat control and technique, you’ll generally need more specialized training and hands-on practice to weld it reliably.

You’ll face a steeper learning curve: mastering TIG or MIG welding parameters, oxide removal, and filler selection requires focused instruction and supervised practice.

That specialized training translates into higher labor expertise and credentialing expectations, which providers factor into hourly rates.

Providers factor higher hourly rates to cover advanced training, certifications, and the greater expertise aluminum welding demands.

Labor time also increases: thicker aluminum often needs multiple passes, interpass temperature control, and slower travel speeds, extending shop hours versus typical plastic repairs.

Because you’ll rely on advanced welding techniques and experienced operators, per-hour charges rise and job throughput falls.

In short, skill acquisition and increased labor time make aluminum welding costlier than most plastic welding scenarios.

Process Complexity and Quality Control Requirements

Having covered how skill and labor time raise aluminum welding costs, it helps to look at how process complexity and quality control amplify those differences.

You’ll face greater process intricacies with aluminum: high-amperage power sources (often 200–300 A), AC or square-wave capability, and rigorous surface prep for oxide removal and joint fit-up. That equipment and preparation escalate capital and cycle costs compared with simpler plastic welding tools.

Your quality-control burden rises too; aluminum’s heat sensitivity requires precise control of amperage, travel speed, and cooling to avoid distortion or porosity. You must implement tighter monitoring standards, documented parameter control, and often non-destructive inspection, all increasing operational expense.

In short, complexity and QC demands make aluminum welding materially costlier to manage.

Typical Applications and Lifecycle Cost Considerations

When you compare typical applications, factor the initial equipment outlay—AC TIG and HF systems for aluminum can be several times more expensive than basic plastic welders.

Also quantify operating and consumable costs: aluminum requires pricier filler wires and sensitive components with tighter maintenance schedules, while plastic uses cheaper fillers or adhesives.

Finally, assess long-term repair cycles and labor: aluminum’s higher upfront and training costs can be offset by reduced frequency of repairs due to greater durability, whereas plastics may incur lower initial costs but higher repeat repair rates.

Initial Equipment Outlay

If you’re budgeting for initial equipment outlay, expect aluminum welding to demand a substantially higher upfront investment and ongoing lifecycle costs than basic plastic welding.

You’ll face an initial investment of $1,000–$3,000 for MIG machines or $2,000–$3,000 for quality TIG units, plus 230V power upgrades where required.

By contrast, plastic welding tools can start near $50 with minimal power needs.

Prioritize equipment durability when comparing total cost of ownership: aluminum rigs require higher-amperage components (200–300 A), more maintenance, and specialized consumables that accelerate wear.

Those factors raise lifecycle cost even before operating expenses.

For precise procurement, factor capital cost, expected duty cycle, maintenance schedules, and replacement intervals to model true long-term expenditure.

Operating and Consumables

Now that you’ve accounted for capital outlay, operating expenses and consumables become the dominant factors in total lifecycle cost.

You’ll find aluminum welding demands specialized consumables — argon shielding gas, aluminum filler wire, and faster-wearing contact tips and nozzles — which elevate per-job spend versus minimal plastic filler rods.

Typical applications reflect different priorities: aluminum’s structural roles require durable, high-integrity joints, increasing consumable use and maintenance frequency.

Your labor costs rise too, since complex welding techniques and sensitivity to material properties require more training and time.

By contrast, plastic welding suits repairs and noncritical parts, with lower consumable and replacement-component rates and simpler techniques.

Quantitatively, lifecycle cost models should weight consumable burn rates, maintenance intervals, and labor skill premiums for aluminum.

Long-Term Repair Cycles

Because aluminum repairs demand specialized skills and equipment, their long-term repair cycles tend to be less frequent but costlier per event than plastic. You should model that trade-off explicitly in lifecycle analyses.

You’ll factor higher capital cost (TIG/MIG units ~$2,000–$3,000) and likely professional labor into each aluminum service event, reducing repair frequency but increasing per-event expense.

Plastic welding uses low-cost tools (<$100) and often on-site fixes, raising repair frequency but lowering unit cost.

Assessments should quantify expected repair frequency, predicted material durability, and cumulative lifecycle cost to compare total cost of ownership.

- Quantify repair frequency vs. per-event cost for each material

- Model material durability impact on replacement intervals

- Include capital, labor, and outsourcing probabilities

When Plastic Welding Becomes the More Expensive Choice

When a plastic repair calls for specialized gear or reinforcement materials, you’ll quickly see costs climb above those for aluminum welding.

You must often invest in specialized equipment — temperature-controlled hot-air welders, extrusion units — ranging from tens to thousands of dollars; that capital outlay alone can exceed typical aluminum setups.

Add filler materials: stainless-steel mesh, fiberglass cloth, compatible thermoplastic rods — and per-job consumable costs rise.

Recycled or degraded polymers may demand larger, more complex remediation, lengthening cycle time.

Because plastics conduct heat poorly, welding is slower, increasing labor hours.

If you lack experience, training expenses or lower first-pass yield further inflate totals.

In aggregate, these factors can make plastic welding the more expensive choice for certain repair scenarios.

Choosing the Right Method for Budget and Performance

If you’re balancing upfront cost against long-term performance, match the welding method to project frequency, material demands, and required joint properties.

You’ll assess budget constraints and performance expectations: aluminum demands higher capital (TIG machines ~$2,000–$3,000) and specialized filler (e.g., 5356), plus skilled labor or training; plastic welding offers low-cost tools (<$100) and cheaper filler, enabling DIY repairs.

Choose aluminum when recurring, structural, or high-temperature applications justify equipment amortization and professional rates. Choose plastic for infrequent, cosmetic, or low-stress repairs where lower initial outlay meets performance expectations.

- For high-frequency projects: prioritize aluminum for durability and long-term ROI.

- For occasional fixes: prioritize plastic to minimize capital expense.

- For mixed needs: evaluate per-job cost vs. required joint properties.

Frequently Asked Questions

Can Either Method Be Reversed or Recycled More Easily?

You can reverse and recycle welded joints differently: aluminum welding supports established recycling processes and higher material sustainability via remelting; plastic welding offers chemical recycling or mechanical reclaiming but often yields lower material sustainability and purity.

Do Environmental Regulations Affect Welding Costs Differently?

Like tuning a complex engine, you’ll see environmental compliance and regulatory impacts raise aluminum welding costs more often; you’ll need stricter controls, fume extraction, and recordkeeping, whereas plastic welding faces fewer emissions but still demands material-specific controls.

How Does Joint Accessibility Impact Method Choice?

You’ll choose methods based on joint design and accessibility challenges: tight, complex joints push you toward smaller torches, specialized fixturing or robotic manipulators, while open, simple designs let you use standard welding or welding-grade plastic fusion equipment efficiently.

Are Hybrid Metal-Plastic Assemblies Common and Costly?

Like a steam-powered clock, you’ll find hybrid metal-plastic assemblies are common but complex; you’ll face hybrid assembly challenges—material compatibility, fastening, sealing—and cost comparison factors include design, tooling, testing, and lifecycle maintenance.

What Are Typical Warranty Differences Between the Two Methods?

Warranty comparison: you’ll see metal welds often carry longer service longevity guarantees (5–10 years) with stricter fatigue and corrosion clauses, while plastic welds usually get shorter warranties (1–3 years) focused on joint integrity and UV resistance.

Conclusion

Think of choosing between aluminum and plastic welding like picking tools from a craftsman’s chest: you’ll match the tool to the job, budget, and skill. You’ll find aluminum often demands pricier gear, skilled hands, and stricter quality checks, while plastic can hide long-term costs in material variability and repair frequency. You’ll weigh upfront capital, labor rates, and lifecycle performance; pick the method whose predictable variables best align with your specification, risk tolerance, and total-cost targets.