To calculate TIG welding cost step-by-step, identify base metals, joint geometry and weld length, then set amperage, travel speed and filler type to compute weld volume and filler weight. Convert length and speed to arc time and add prep/finishing allowances (20–30%) for total labor hours, multiply by the welder’s hourly rate. Add costs for filler rods, shielding gas consumption, electrode wear, equipment depreciation, utilities and a 10–20% contingency. Follow the full method for worked examples and templates.

Understanding TIG Welding Cost Components

When you estimate TIG welding costs, start by breaking the job into five measurable components: labor (driven by welder skill and task complexity), materials (base metals, filler rods, and shielding gas), equipment (purchase, lease, depreciation, and maintenance of TIG machines), overhead (workspace, utilities, and administrative support), and ancillary work (surface preparation and post‑weld inspection/finishing).

You’ll quantify labor by hourly rates adjusted for skill level and task complexity. Material costs require up-to-date pricing for base metals, filler rods and shielding gas, factoring market volatility.

Equipment costs encompass acquisition, rental alternatives, depreciation schedules and maintenance frequency. Overhead must be allocated per job using workspace footprint and utility consumption.

Account for equipment acquisition, rental options, depreciation, maintenance, and allocate overhead by workspace footprint and utilities.

Finally, include ancillary operations like cleaning and inspection. Use this breakdown for rigorous TIG welding cost analysis.

Defining Scope and Selecting TIG Parameters

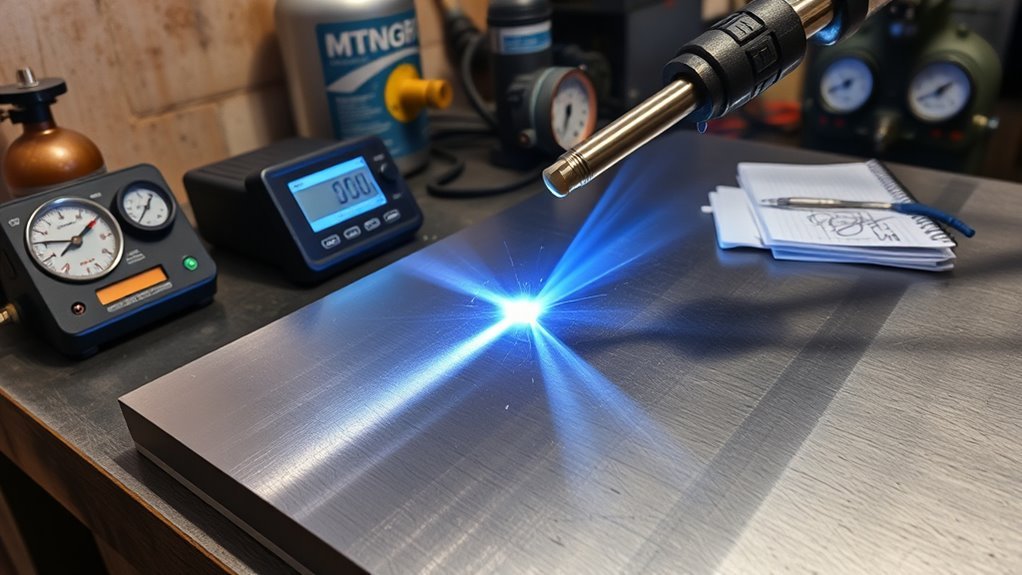

Having quantified labor, materials, equipment and overhead, you now define the weld scope and choose TIG parameters that will drive those cost elements.

You identify base metals and required filler; different alloys dictate filler chemistry and shielding gas.

Specify joint preparation—single or double-V, root gap, bevel angle—and calculate joint length to estimate filler volume and weight using material density.

Determine amperage, travel speed and shielding gas flow to achieve penetration targets.

For tungsten selection, choose electrode type and diameter to match current and metal thickness; record expected electrode life and replacement rate.

Document all parameters methodically so consumable usage, equipment duty cycles and shielding consumption feed directly into your cost model.

Calculating Labor Time and Skilled Welder Rates

Because accurate labor estimates hinge on weld length, joint complexity and travel speed, start by calculating arc time from measured weld length divided by the welder’s travel speed.

Then add allowances for joint preparation and post-weld finishing (typically 20–30% extra) and adjust for the welder’s efficiency/duty cycle to arrive at the total productive hours required.

Next, quantify welding complexity to determine required skill level and whether multiple operators are needed simultaneously.

Convert productive hours to labor cost by multiplying by the appropriate hourly rate; skilled TIG welder rates typically range $20–$50/hr, varying with welder experience and region.

Finally, include any shift overlaps or supervision time and sum costs for the project duration to produce a definitive labor estimate.

Estimating Materials, Gas, and Consumables

Although TIG welding quality hinges on technique, accurate cost estimates start with quantifying materials, gas, and consumables for the specific joint geometry and process parameters.

You calculate base-metal and filler-metal quantities from joint dimensions and weld volume, then apply a reasonable material loss percentage to cover waste and errors.

For shielding gas, use typical consumption (12–15 L/min) and cylinder capacity (~10,000 L) to convert welding hours to cylinder usage; this yields roughly 10–12 hours per cylinder under nominal gas efficiency.

Include supplier quotes for filler rods and tungsten electrodes, noting price differences by alloy.

Track electrode care and handling procedures to reduce consumable turnover.

Summarize totals for metal, gas, and consumables separately so you can update estimates as parameters change.

Adding Equipment, Overhead, and Contingency

When you move beyond materials and consumables, add equipment costs, overhead, and contingency so your estimate reflects true project expense; include depreciation or rental fees for TIG machines, scheduled maintenance, and any ancillary gear (chillers, wire feeders, fixturing, and gas regulators), and calculate their cost per welding hour. You’ll quantify equipment depreciation and rental, measure power consumption per hour, and record scheduled maintenance intervals. Apply overhead expenses (utilities, rent, admin, safety gear) as 15–30% of subtotal. Add contingency 10–20% for unforeseen issues. Use the table below to structure inputs and derive a per-hour rate.

| Item | Rate basis | Notes |

|---|---|---|

| Machines | $/hour | depreciation + maintenance |

| Utilities | % or $/hour | power consumption |

| Contingency | % | 10–20% of total |

Frequently Asked Questions

Can TIG Welding Costs Be Reduced by Outsourcing to a Different Region?

Yes — you can reduce TIG welding costs by outsourcing to a different region; you’ll evaluate outsourcing benefits, regional pricing, quality control, logistics, and compliance, then quantify labor, material, transport, and risk to decide methodically.

How Do Warranty or Liability Considerations Affect Final TIG Pricing?

46% of claims stem from fabrication defects, so you’ll factor warranty impact into unit pricing, adjust for extended liability coverage premiums, document limits, and set contingency rates methodically to guarantee pricing covers potential claim exposure.

Do Surface Finish or Cosmetic Requirements Change Cost Significantly?

Yes — surface finish and aesthetic preferences greatly affect cost; you’ll need finer grinding, polishing, or filler adjustments, increasing labor, time, inspection, and consumables. You’ll quantify added hours and processes to update pricing precisely.

Can Automation or Robots Ever Be Cheaper Than Manual TIG Here?

Yes — you can find robots cheaper long-term: when you quantify robot efficiency and perform a cost comparison, you’ll model capital, maintenance, throughput, cycle-time reduction, and quality gains to justify automation versus manual TIG labor.

How Do Currency Fluctuations Impact International Material Cost Estimates?

You’ll see currency exchange swings alter quoted prices, forcing you to adjust material sourcing buffers, apply forward contracts or hedging, and recalc landed costs methodically to maintain margin accuracy and procurement schedules across international suppliers.

Conclusion

You’ve now got the methodical framework to price TIG jobs: break costs into labor, materials, gas, consumables, equipment, overhead, and contingency, then calculate using chosen parameters and scope. Note that skilled TIG welders often charge 30–50% more than MIG welders; industry surveys show TIG rates average about 45% higher due to skill and time intensity. Use precise time estimates and part-specific consumable counts to keep estimates accurate and defensible.