You can picture a clean welding booth, torch glowing, test coupon waiting on the table; you want to know what getting certified will cost. You’ll usually pay $460–$520 for the basic test depending on code and position, but don’t stop there — add PPE, tools, materials, and possible retest fees and totals rise quickly. Keep going to see a clear breakdown, savings tips, and where to take the exam.

Typical Price Range for Welding Certification Tests

You’ll typically pay between $460 and $520 for a standard welding certification test, though specific codes like AWS D1.1 or ASME IX and test scope can push some fees higher.

You’ll find that base fees cover the practical qualification for a single position and thickness; retests usually run about $120 to $250 per position.

If you want the AWS Accredited Test Facility (ATF) Upgrade—which adds registry entry and a certification card—expect roughly $155 to $165 more.

Some AWS D1.1 tests, depending on thickness and position, can reach $685 with the ATF Upgrade included.

Send-in test kits offer flexibility in scheduling and location and may affect total cost modestly.

When you weigh welding certification benefits, include long-term earning potential and broader job access against upfront costs.

Explore funding options early: employer sponsorships, apprenticeship programs, and workforce grants often offset fees and speed your return on investment.

Breakdown of Certification Fees by Code and Test Type

Start by separating costs by code and test type so you can compare options quickly. You’ll find fees vary by certification types and by test specifics; methodically list them so decisions are clear. Tests run mainly Tuesdays and Thursdays at 8:00 AM, and bring a picture ID and required safety gear to the testing locations.

| Code / Test | Fee | Notes |

|---|---|---|

| AWS D1.1 3/8″ V&O | $460 | ATF upgrade: $615 total |

| AWS D1.1 1″ V&O | $520 | ATF upgrade: $685 total |

| ASME IX 6G (Stick/MIG/TIG) | $460 | Retest: $120 |

Retest fees for AWS D1.1 are $250 per position; factor that into your budget if you anticipate repeats. Scheduling constraints at testing locations can limit options, so book early. This breakdown helps you tally base costs, upgrade choices, and potential retest liabilities with precision.

Additional Costs: Equipment, PPE, and Materials

You should budget for personal protective equipment—helmets, gloves, jackets and respirators—which typically adds $100–$500 and must be maintained for compliance.

Factor in essential welding tools and machines, which can range from $500 to $2,000 depending on type and specs.

Also account for consumables and materials (electrodes, wire, shielding gas, and study supplies) plus potential retest fees of $120–$250 per position.

Personal Protective Equipment

Although budgeting for tuition and shop fees is essential, you’ll also need to account for equipment and consumables that can add several hundred to a few thousand dollars to certification costs.

You’ll invest in PPE and related items to meet welding safety standards and guarantee proper gear maintenance. Expect PPE costs from $100–$500 depending on quality.

- Safety glasses: basic eye protection, inexpensive to replace

- Welding helmet: auto-darkening models cost more but improve consistency

- Gloves: heat-resistant options vary by material and price

- Flame-resistant clothing: essential for certification environments

- Consumables and filler metals: ongoing expense during practice

Plan for a welding machine ($500–$2,000) and $100–$500 for books and supplies when finalizing your budget.

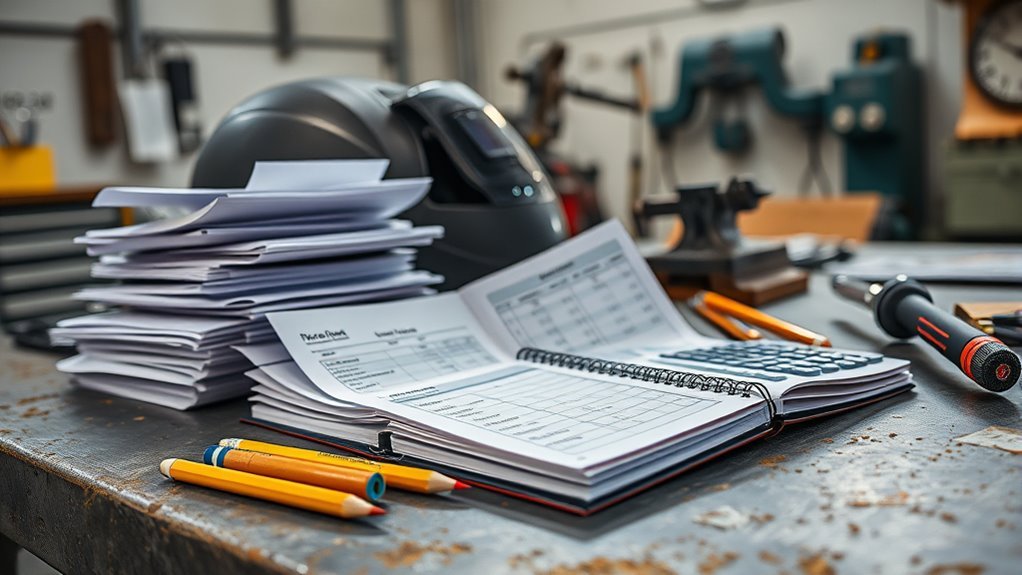

Essential Welding Tools

Having covered PPE and basic consumables, it’s time to itemize the tools and gear you’ll actually use in the shop so you can build a realistic budget.

You’ll plan for welding machines ($500–$2,000), plus hand tools (grinders, clamps, chipping hammers) and a sturdy workbench; combined essentials typically total $500–$1,500 depending on quality.

Add PPE—helmets, gloves, safety glasses—estimated at $100–$500.

When budgeting for certification, separate equipment purchase from consumables to avoid overlap.

Account for periodic equipment maintenance and replacement parts in your projections, since neglect raises long-term costs.

Finally, match tool selection to the welding techniques you’ll learn; choosing appropriate machines and accessories reduces rework and supports consistent practice during training.

Consumables and Materials

Consumables and materials form a predictable portion of your certification budget, so plan for welding rods, filler wire, shielding gases, grinding discs, and replacement contact tips that you’ll use up during practice and testing.

You’ll typically budget $100–$500 for these consumables and PPE; machines and course supplies add more, so isolate material costs when estimating total investment and certification benefits.

Be methodical: track usage per session, note costs by welding technique, and replace worn PPE promptly.

- Welding rods and filler wire (stick, MIG, TIG)

- Shielding gases and regulators

- Grinding discs and cutting consumables

- Replacement contact tips and nozzles

- PPE consumables (gloves, lenses, filters)

This disciplined approach clarifies ongoing expenses and supports efficient practice.

Certification Retest and Upgrade Fees

If you need to retake a welding certification, expect clearly itemized fees and optional upgrades that alter total cost and credentialing: for example, AWS D1.1 retests run $250 per position, while ASME IX retests are $120, and an AWS D1.1 test with the ATF Upgrade costs $615 (which also registers you in the AWS certified welder registry).

You’ll plan retest strategies around these fixed prices: choose which position to repeat, budget for per-position charges, and schedule practice to minimize repeats.

Assess upgrade benefits objectively; the ATF Upgrade raises your marketability and adds registry administration that explains the higher fee. Confirm that stated prices include materials and examiner time so you won’t face hidden charges.

If you’re weighing options, compare the $250 D1.1 retest to the $120 ASME IX retest by total cost versus career value. Track receipts and documentation from upgrades for employer verification and future credential maintenance.

Where and When Certification Tests Are Offered

At and around six regional sites you can schedule welding certification tests on Tuesdays and Thursdays beginning at 8:00 AM; call or submit an online inquiry to reserve a slot and specify the code (for example, AWS D1.1 or ASME IX) and position you’re testing.

Schedule welding certification tests at regional sites on Tuesdays and Thursdays starting 8:00 AM; call or inquire online to reserve.

You’ll use the same process for scheduling appointments at each testing location. Bring a photo ID and required safety gear on test day; arrive early for check-in and setup.

Locations are fixed and follow a consistent calendar, so plan travel and prep to match available dates.

- Baltimore, MD — central testing hub

- Beltsville, MD — weekday sessions

- York, PA — regional coverage

- Scranton, PA — consistent Thursday availability

- Southern MD & Arnold MD Welding Schools — hands-on lanes

Confirm the exact code tested at your chosen site and any site-specific rules when you call. Records of your appointment and fee schedule will be provided at booking; keep that confirmation until results are issued.

Financial Aid, Grants, and Scholarships for Certification

You should start by mapping available scholarship opportunities from groups like the American Welding Society and your chosen schools to see which match your profile and deadlines.

Check for grants and institutional aid that don’t require repayment, and note eligibility criteria, application materials, and award timelines for each.

Apply to multiple sources—combining scholarships, grants, and, if necessary, federal student loans—so you can minimize out-of-pocket certification costs.

Scholarship Opportunities Overview

Because scholarships and grants can cut certification costs dramatically, start by mapping the funding sources available to you: professional associations (like the American Welding Society), manufacturers and trade companies, community colleges and vocational schools, and state or federal grant programs.

You’ll assess scholarship eligibility, document requirements, and the application process so you target awards you actually qualify for. Check deadlines, GPA or enrollment criteria, and required essays or recommendations. Apply broadly and track submissions.

- American Welding Society scholarships for students entering welding programs

- Manufacturer or trade-company awards tied to apprenticeships

- School-specific scholarships at community colleges and vocational centers

- State workforce development grants that cover tuition

- Need- and merit-based private scholarships with varying criteria

Grants and Aid Tips

While exploring certification costs, prioritize identifying grants and aid that don’t require repayment so you can reduce out-of-pocket expenses quickly and reliably.

Start by listing local, state, and national grant programs, plus scholarships from the American Welding Society and private companies; note eligibility, deadlines, and required documents. Use a spreadsheet to track grant applications, award amounts, and submission dates.

Include federal student loans as a backup—record interest rates and repayment terms for comparison. Apply to multiple scholarships and grants to maximize non-repayable aid, then integrate potential loan costs into your financial planning.

Review award letters carefully, accept funds in the order that minimizes debt, and update your budget as offers arrive to guarantee a cost-effective path to certification.

Apprenticeships and Employer-Sponsored Certification Options

If you join an apprenticeship or employer-sponsored program, you’ll get hands-on training paired with classroom instruction and often have your certification costs covered or heavily subsidized.

You’ll gain apprenticeship benefits through structured tasks, measured skill progression, and direct supervision while employer sponsorship can underwrite testing fees, typically $300–$550 per certification.

Programs vary: some cover full tuition, others pay only testing or specialized certifications relevant to your role. Unions may offer similar packages with formal placement pipelines.

You should document what’s covered before you commit—training length, testing sites, renewal responsibilities, and any employment obligations tied to sponsorship.

- apprenticeship benefits: paid training, progressive skills assessment, and mentorship

- employer sponsorship: testing fees covered, targeted specialty certifications

- union apprenticeships: tuition coverage and placement support

- cost range impact: $300–$550 per external certification

- obligations: service commitments, renewal, and scope of covered tests

Assess offers methodically, prioritize programs that minimize out-of-pocket certification expenses.

How Certification Impacts Earning Potential and Job Prospects

When you earn welding certification, you typically increase your market value—certified welders had a median annual wage of $47,540 in May 2022, and employers often prefer or require specific credentials for specialized roles like aerospace or underwater welding.

You’ll see clearer hiring signals: certifications align your skills with industry demands and current welding trends, making you eligible for roles non-certified peers can’t access.

Certification also creates upward mobility; documented competency lets you pursue supervisory or specialized positions that pay more.

Portable credentials—such as AWS registry entries—expand geographic and sectoral opportunities, so you can follow demand where it exists.

Finally, the certification process itself promotes continuous learning: each renewal or new qualification compounds your technical breadth and long-term earning potential.

In practice, you should view certification as an investment in measurable marketability, not merely a credential. Its value is evident in higher starting pay, broader job listings, and clearer paths to advanced roles aligned with evolving industry demands and technologies.

Tips for Reducing Certification Costs

Start by asking your employer about reimbursement or tuition assistance and document their policy so you can claim eligible costs.

Combine scholarships and grants from trade associations with school financial aid to minimize out-of-pocket expenses.

Prepare using free or low-cost practice tests and targeted study plans so you pass on the first attempt and avoid repeat fees.

Use Employer Reimbursement

Because many employers run reimbursement programs, you can often cut your welding certification outlays substantially by verifying eligibility and following their procedures precisely.

Check employer policies first: verify whether certifications must be job-related, what documentation is required, and any reimbursement limits. Track costs—tests typically run $300–$550—and retain receipts. Submit proof of completion promptly and follow the timeframes set by HR or finance.

- Verify job-related criteria and approval steps

- Note reimbursement limits and percentage covered

- Save itemized receipts and exam confirmations

- Meet submission deadlines and required formats

- Follow up on claims with HR or finance

Be methodical: document every step, record communications, and keep copies of approvals to guarantee timely reimbursement.

Combine Scholarships & Grants

If you combine scholarships and grants strategically, you can cut a large portion of your certification expenses without taking on extra debt.

Start by listing welding-school scholarships, industry funds (like the American Welding Society), and public grant programs; track deadlines and required documents in a spreadsheet.

When preparing scholarship applications, tailor each essay to selection criteria, quantify costs covered, and attach transcripts or recommendations requested.

For grant eligibility, confirm residency, program enrollment, and income thresholds before applying to avoid wasted effort.

Combine awarded scholarships and grants first, then fill remaining gaps with federal loans or employer reimbursement if needed.

Apply to multiple sources—certification fees ($300–$550) add up—so systematic submissions increase your chance of substantial savings.

Prepare to Pass First-Time

After you’ve maximized scholarships and grants to cover fees, focus on strategies that help you pass on the first try so you don’t pay retest charges.

Be methodical: review certification requirements, testing procedures, and the specific welding codes (AWS D1.1, ASME IX) so you know scoring criteria and avoid $120–$250 retest fees per position. Use targeted exam strategies and vetted study resources to close weak spots.

- Take preparatory courses or workshops focused on required techniques and codes.

- Use practice tests from schools or professional organizations to simulate exam conditions.

- Choose programs offering bundled training plus testing to lower total cost.

- Track competency with a checklist of mandatory skills and weld types.

- Apply for certification-specific scholarships or grants before enrolling.

Preparing for Your Welding Certification Exam

When you prepare for your welding certification exam, start by studying the specific code you’ll test on (for example, AWS D1.1 or ASME IX) and map out the exact positions and processes—TIG, MIG, plate thicknesses, joint types—that the exam requires.

You’ll use focused exam strategies: list required weld positions, allowable variables, and acceptance criteria from the code. Create a study schedule that allocates time to theory, code review, and hands-on sessions.

Apply practice techniques that mirror test conditions: set up identical materials, tooling, and safety gear; time your welds; and record settings for repeatability.

Bring required items to the test site—photo ID, PPE, specified tools—and verify facility rules in advance. Consider a targeted prep course or workshop to bridge skill gaps and get instructor feedback.

Track progress with checklists and mock tests. Budget for exam fees ($300–$550) and possible retest charges so administrative details won’t derail your focus on welding performance.

Frequently Asked Questions

Do Certification Fees Vary by State Licensing Requirements?

Yes — you’ll encounter varying state requirements that affect certification costs; you’ll need to compare jurisdictions, factor exam fees, training expenses, renewals, and any endorsements, and budget accordingly to meet each state’s specific licensing criteria.

Will Certification Transfer Between Countries or International Employers?

About 60% of employers accept some foreign welding credentials, but you’ll still need verification: check international recognition and certification equivalence, obtain endorsements or testing, and follow precise reciprocity procedures for each country or employer.

Are There Age or Education Prerequisites for Taking Certification Tests?

You usually won’t face strict age limitations, though some programs set minimums; you’ll need to meet basic education requirements (high school diploma or equivalent often preferred) and any specific course or training prerequisites before testing.

Can You Appeal a Failed Certification Test Result or Request a Review?

Yes—you can often appeal or request a review; check test retake policies first, then follow the review process options provided by the certifying body, submit required forms, evidence, and comply with timelines and fees for reassessment.

Do Welding Certifications Expire if Unused for Several Years?

Yes — and coincidentally, if you leave it unused, many certs do expire: you’ll need to check expiration policies precisely, because certification renewal often requires retesting, refresher training, or documented recent welds to regain validity.

Conclusion

You’ll likely pay $460–$520 for a basic welding certification, and coincidentally the extra $700–$2,500 for PPE, tools, and consumables often matches the cost of a beginner’s first month of living expenses — a stark reminder that investment in safety and skill arrives with life’s other bills. Plan for $120–$250 per retest, pursue apprenticeships or employer sponsorships, and prepare methodically so your upfront cost accelerates long‑term earning potential.